Power factor compensation control circuit of self-turn-off device

A power factor compensation and control circuit technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as inability to adapt to dynamic control compensation current, restricting the promotion and application of compensation equipment, and complex structure of compensation equipment , to achieve the effect of reducing the number of control circuits, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

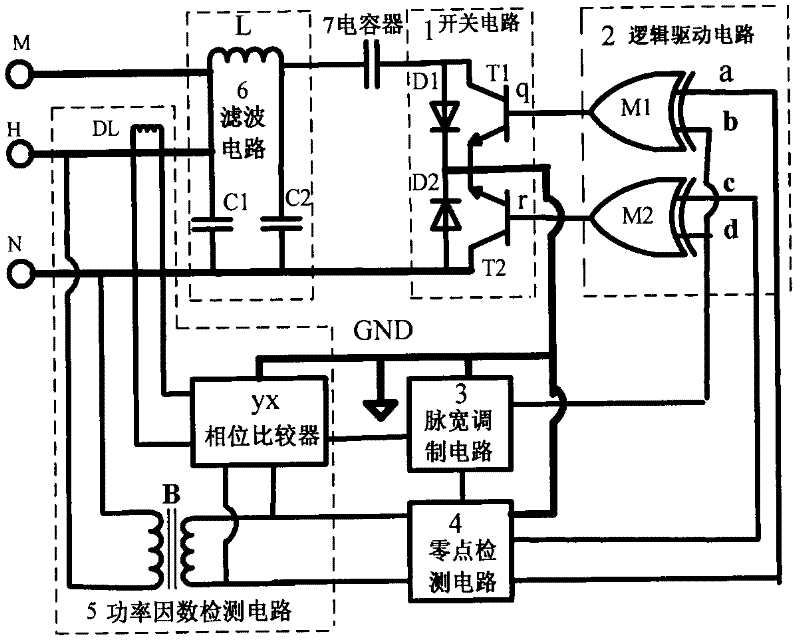

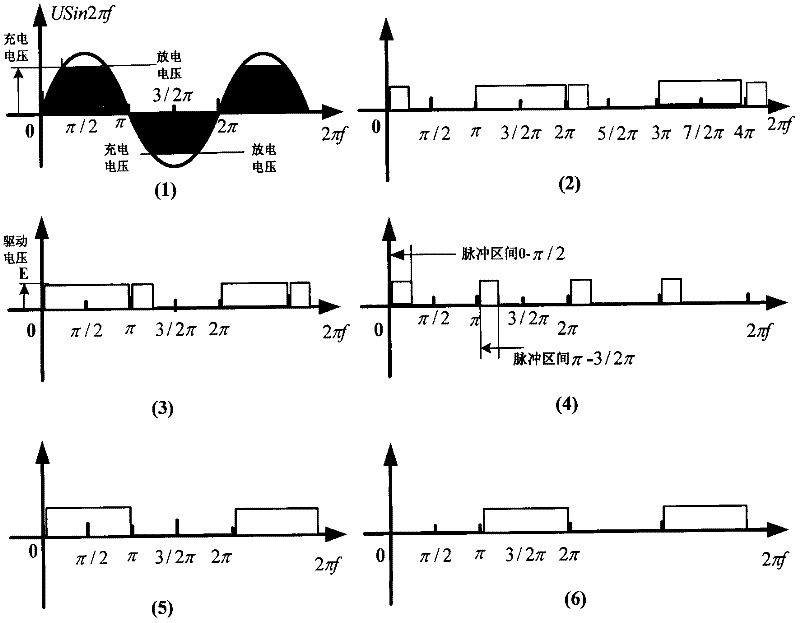

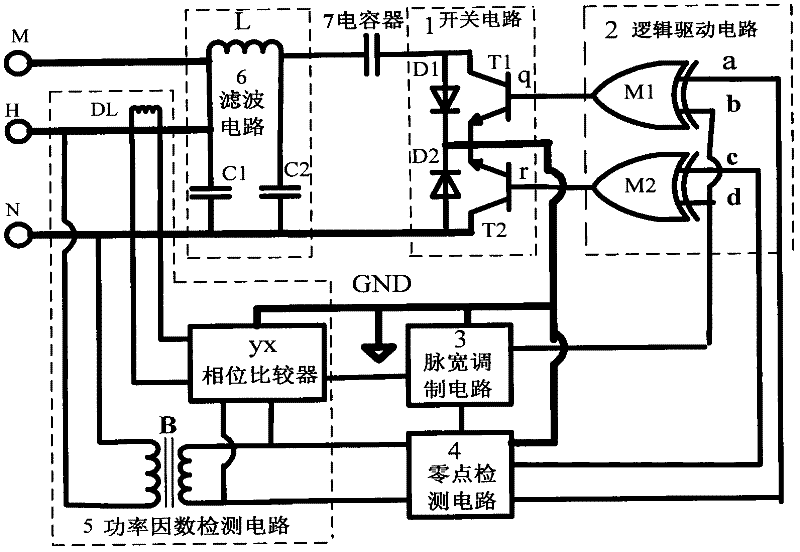

[0029] The invention is a self-shutdown device power factor compensation control circuit. figure 1 It is a schematic circuit diagram of a self-shutdown device capacitor power factor compensation control device implemented by the circuit. The circuit consists of a switch circuit 1, a logic drive circuit 2, a pulse width modulation circuit 3, a zero point detection circuit 4, a power factor detection circuit 5, a filter circuit 6, a capacitor 7, an AC input terminal H, an output terminal M and a common terminal N. . When the input terminal H and the common ground terminal N are connected to the AC power, the output terminal M and the common ground terminal N are connected to the load, the current is filtered by the capacitor C1, the inductance L, and the capacitor C2 in the filter circuit 6, and then the capacitor 7 passes through the switch ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com