Flow device comprising a cavity cooling system

A technology of flow device and cavitation, which is applied to parts of pumping devices for elastic fluids, air transportation, engine components, etc., can solve problems such as temperature life and strength temperature limitations, achieve geometric shape optimization, improve life, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

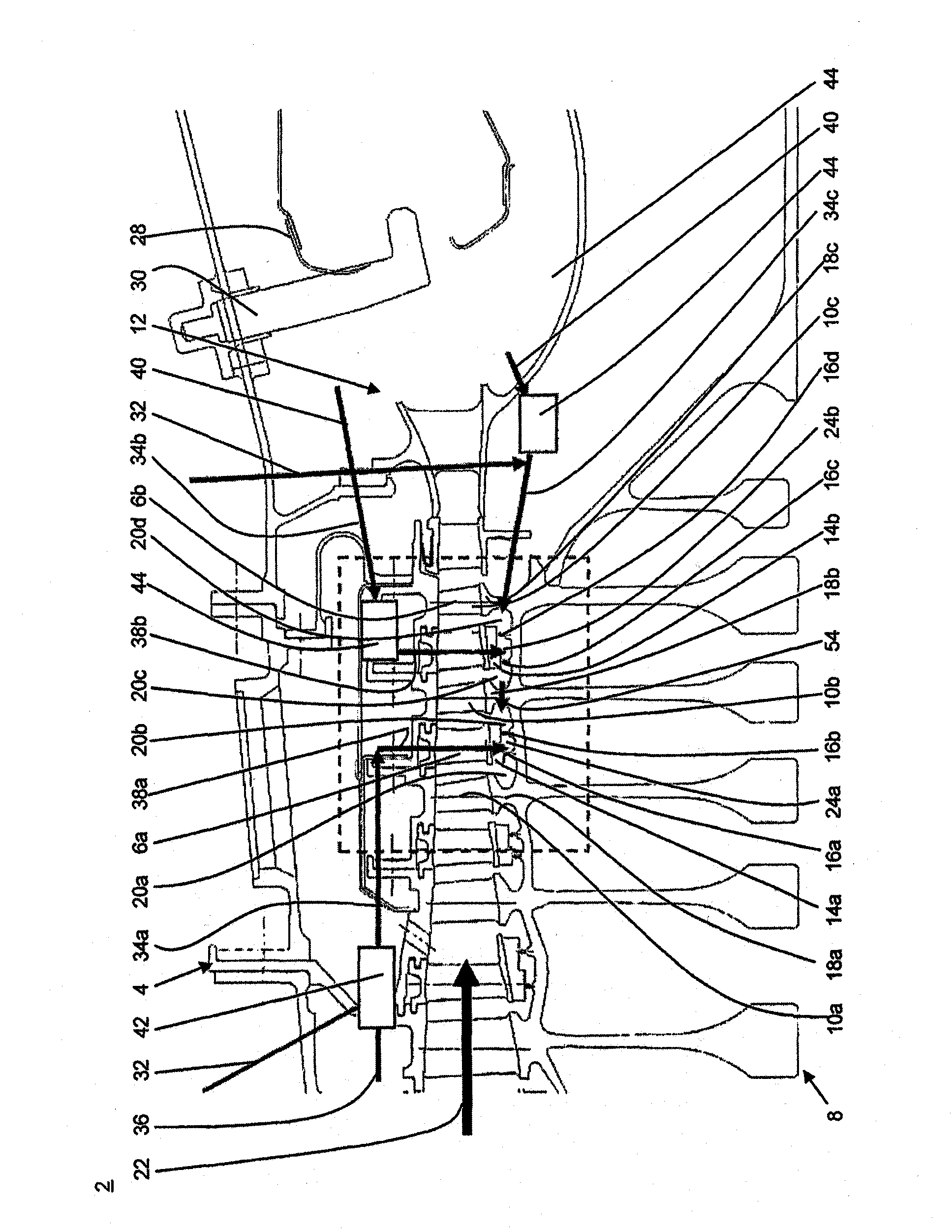

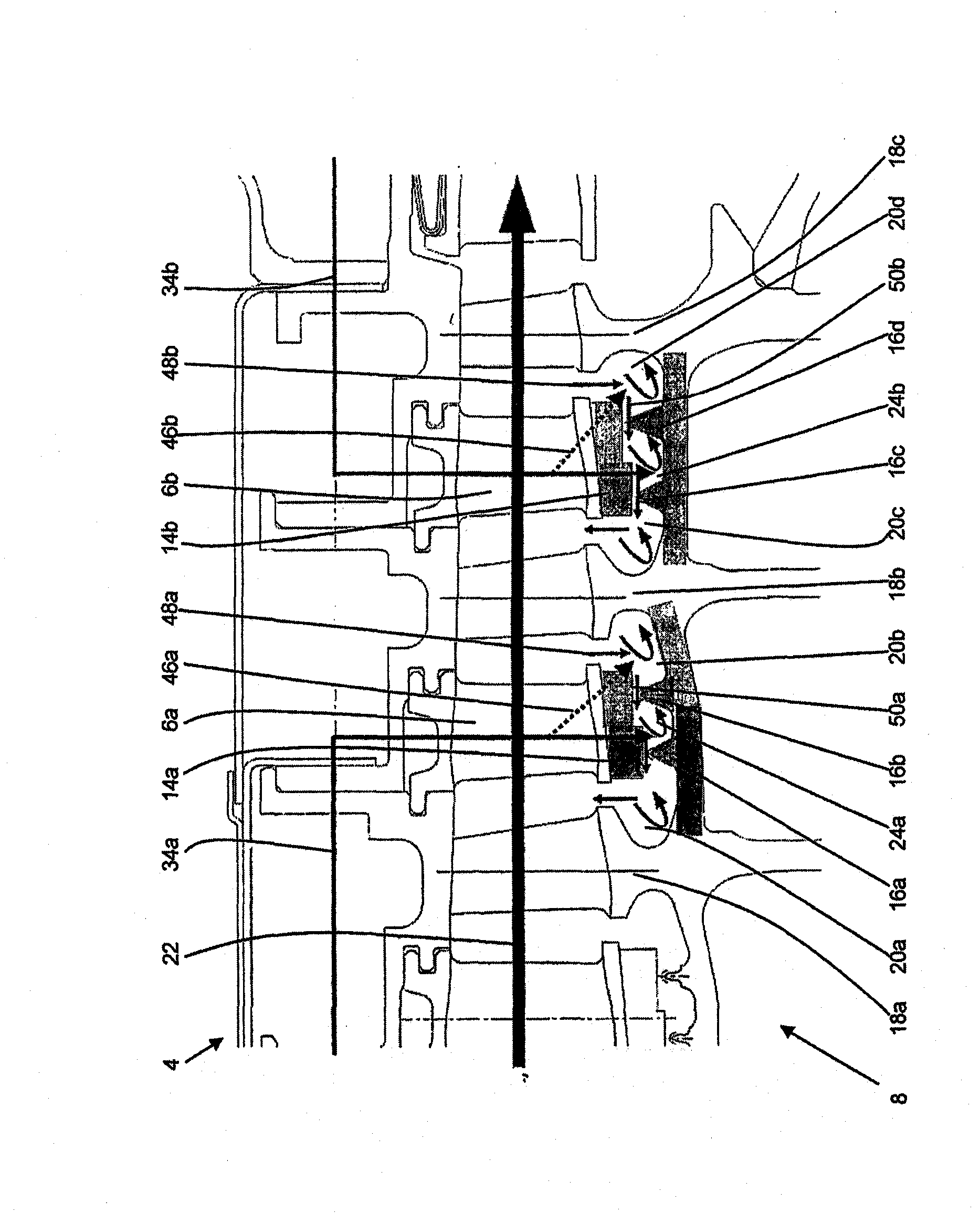

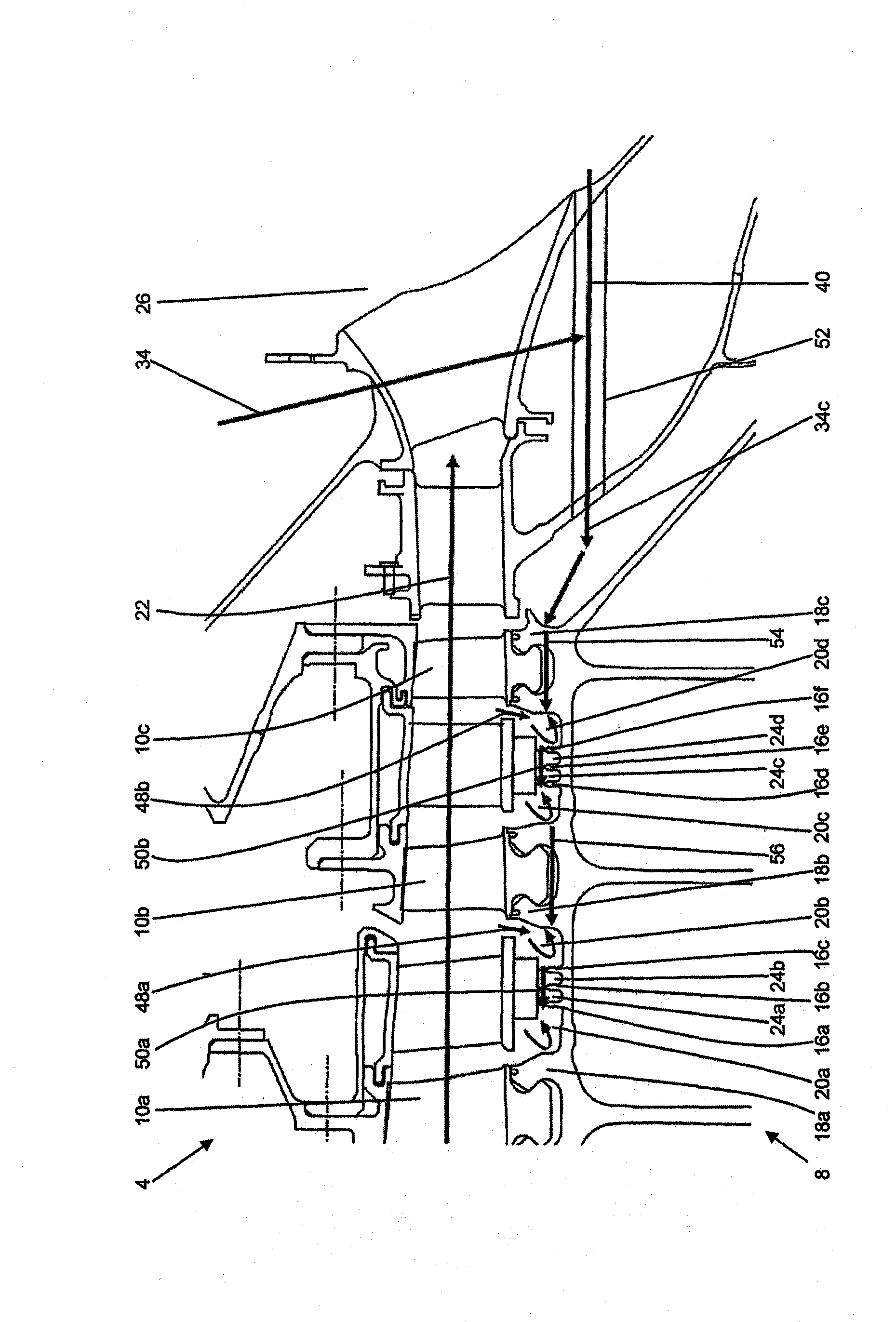

[0017] figure 1 A longitudinal section through the high-pressure region of a flow device designed as a compressor 2 with a cooling air injection system according to the invention is shown. here, in figure 1 Various types of cooling air injection systems are shown in , which can be operated individually or in combination with each other.

[0018] The compressor 2 has an axial design and is part of a gas turbine, in particular an aircraft engine. It has a multi-part housing 4 which supports a plurality of guide vanes 6a, 6b and in which a rotor 8 with a plurality of rotor blades 10a, 10b, . . . is rotatably mounted. Guide vanes 6 a , 6 b and rotor blades 10 a , 10 b , .

[0019] The guide vanes 6a, 6b each bear at their tips a wrapping strip which is provided on its side facing the rotor 8 with a honeycomb-shaped and plate-shaped sealing element 14a, 14b.

[0020] On the rotor side facing the sealing elements 14a, 14b radial flange-shaped or land-shaped sealing bodies 16a, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com