Textile laser engraving system and method

A technology of laser engraving and textiles, applied in the field of laser engraving systems, can solve the problem of single pattern color and achieve realistic patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

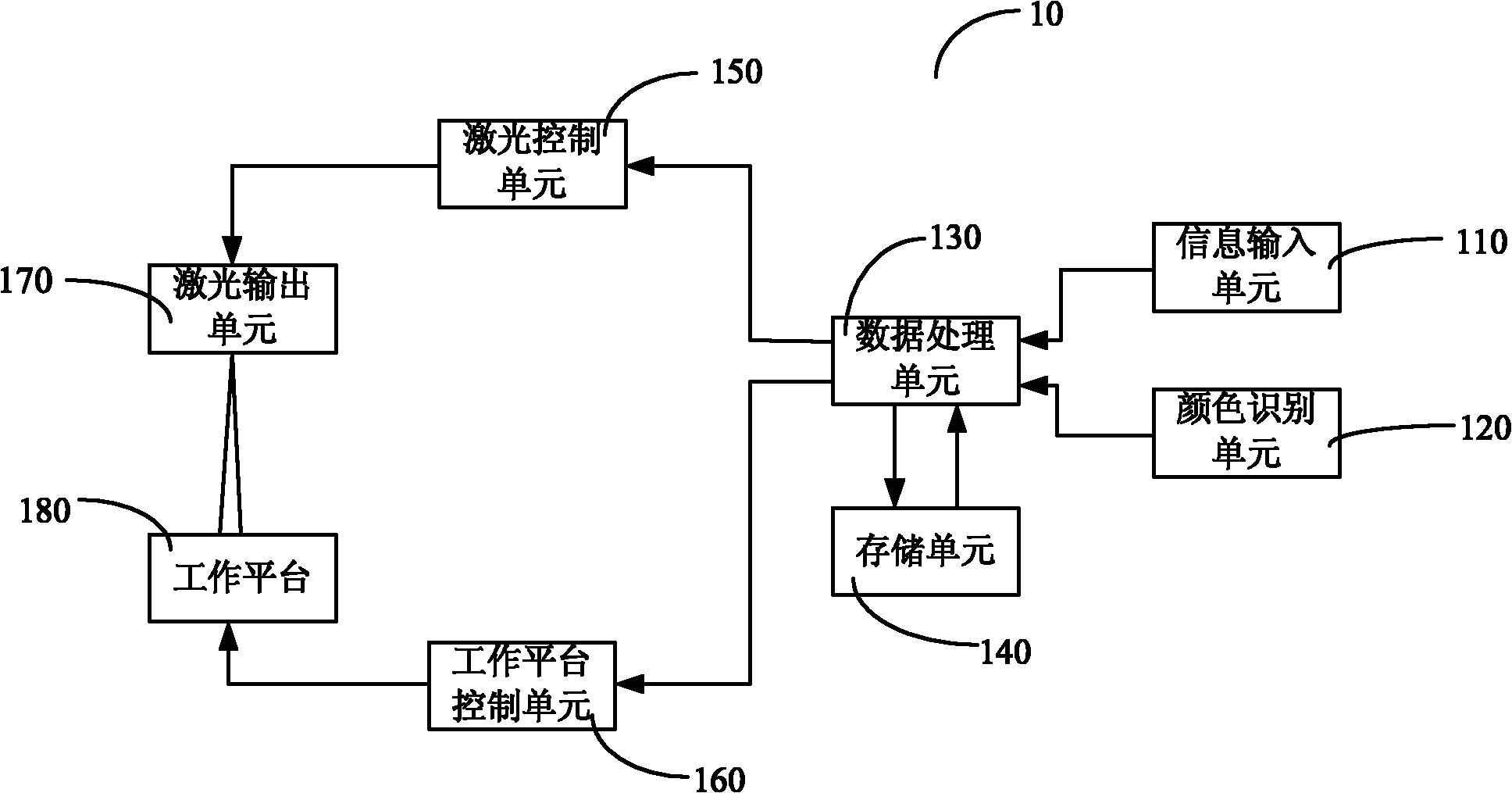

[0024] This embodiment proposes a laser engraving system 10 for textiles. The laser is irradiated on the textiles for high-temperature etching. The yarns at the parts subjected to high-temperature etching are ablated and the dyes are gasified, so that the color of the textiles changes, and the color of the textiles The difference in texture, laser wavelength, power, frequency and irradiation time will cause different changes in the color of the etched textiles. The laser engraving system 10 of the present invention controls the tilt, rotation, movement and CO of the working platform 180. 2 The laser 170 outputs laser light with a specific wavelength, power, frequency and shape to generate desired color patterns on textiles (not shown in the figure).

[0025] Such as figure 1 Shown is a functional block diagram of the textile laser engraving system 10 of the present invention. The system 10 includes an information input unit 110, a color recognition unit 120, a storage unit 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com