Method for preparing ethylbenzene and styrene by side-chain alkylation reaction of toluene with methanol

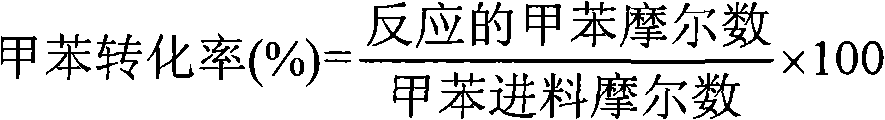

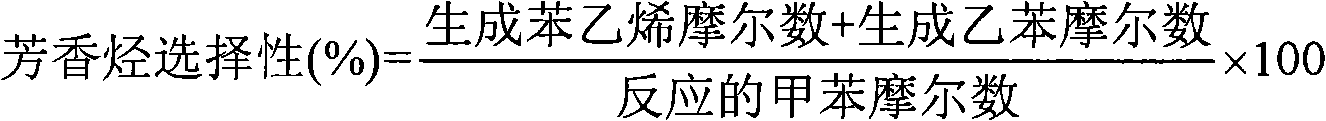

A technology of alkylation reaction and styrene, applied in the field of preparation of ethylbenzene and styrene, can solve the problems of low conversion rate of toluene, low selectivity of ethylbenzene and styrene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 0.15mol of KHCO 3 Dissolve in 300ml of water to prepare a solution with a concentration of 0.5mol / L and divide it into three equal parts, add 10g of 13X molecular sieve to one of the solutions, stir for 2 hours under the condition of heating an oil bath at a temperature of 60°C, and then Put the filtered molecular sieve into the second part of the solution and stir for 2 hours under the same temperature of 60°C in an oil bath, and then put the filtered molecular sieve into the third part of the solution. Stir under bath heating conditions for 2 hours, place the filtered molecular sieve in an oven at 100°C for 24 hours, take it out and raise the temperature from room temperature to 600°C for 6 hours in a nitrogen atmosphere, and keep the temperature at 600°C for 6 hours to obtain a catalyst material (catalyst I) .

[0016] With catalyst I as reaction catalyst, raw material toluene and methyl alcohol are with molar ratio 5: 1, with 2.0 milliliters / hour (raw material weig...

Embodiment 2~11

[0018] Prepare and evaluate the catalyst according to the various steps and conditions of Example 1, just change the concentration, exchange temperature and solid-liquid weight ratio of the potassium salt solution used in the catalyst preparation process, its composition is listed in Table 1, and its evaluation results are listed in Table 1 2.

[0019] The preparation method of catalyst in each example of table 1

[0020] Numbering

potassium salt

Solution concentration (mol / L)

Exchange temperature (℃)

solid-liquid weight ratio

Example 1

KHCO 3

0.5

60

1∶10

Example 2

KHCO 3

1

50

1∶5

Example 3

KHCO 3

1

80

1∶10

Example 4

KHCO 3

1

90

1∶8

Example 5

KHCO 3

1.5

80

1∶10

Example 6

KHCO 3

2

80

1∶10

Example 7

KHCO 3

2.5

80

1∶10

Example 8

K2...

Embodiment 12~18

[0024] Prepare catalyst according to each step listed in embodiment 1 and embodiment 3 concentration, temperature and solid-liquid weight ratio, just change evaluation condition, and its evaluation condition is listed in table 3, and its evaluation result is listed in table 4.

[0025] Table 3 Different evaluation conditions in each example

[0026] Numbering

Toluene to methanol molar ratio

Reaction temperature (°C)

Reaction pressure (MPa)

Raw material mass space velocity (hour -1 )

Example 3

5∶1

450

0

2

Example 12

0.1∶1

200

0.5

0.5

Example 13

2∶1

350

0.2

1

Example 14

3∶1

400

0.1

3

Example 15

4∶1

500

0

5

Example 16

6∶1

600

0

6

Example 17

7∶1

450

0

8

Example 18

10∶1

600

0

10

[0027] Table 4 Evaluation results under differen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap