Patents

Literature

33results about How to "High toluene conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

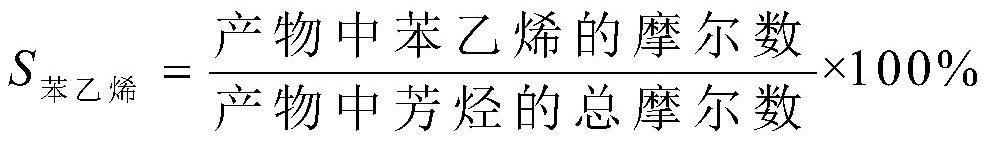

Preparation and application of high-performance toluene side-chain alkylation catalyst

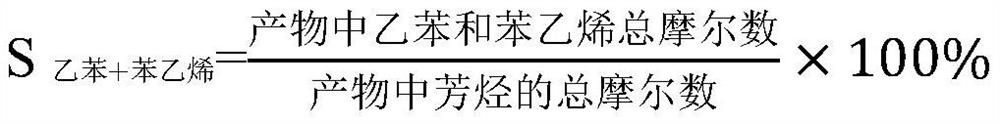

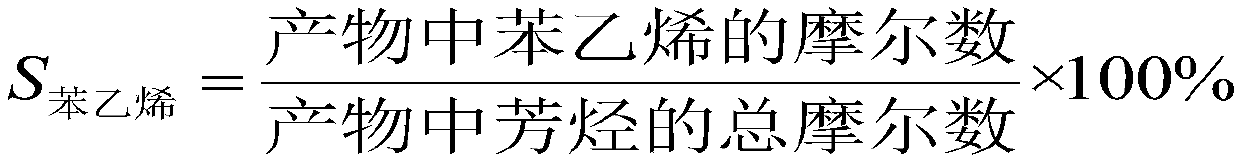

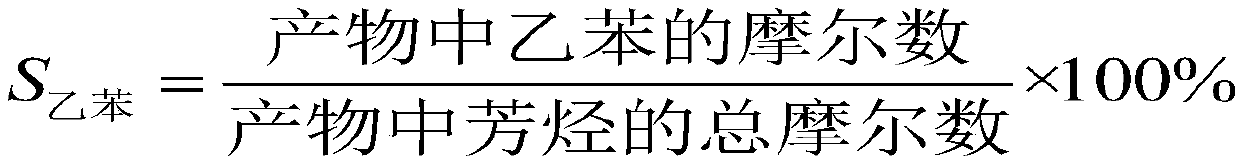

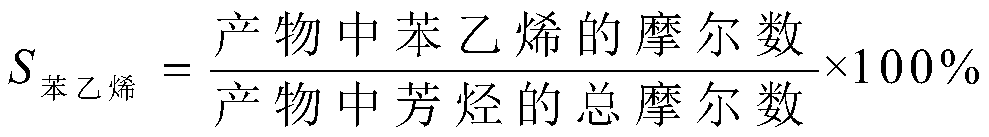

ActiveCN106179459AHigh selectivityHigh toluene conversionMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkyl transfer

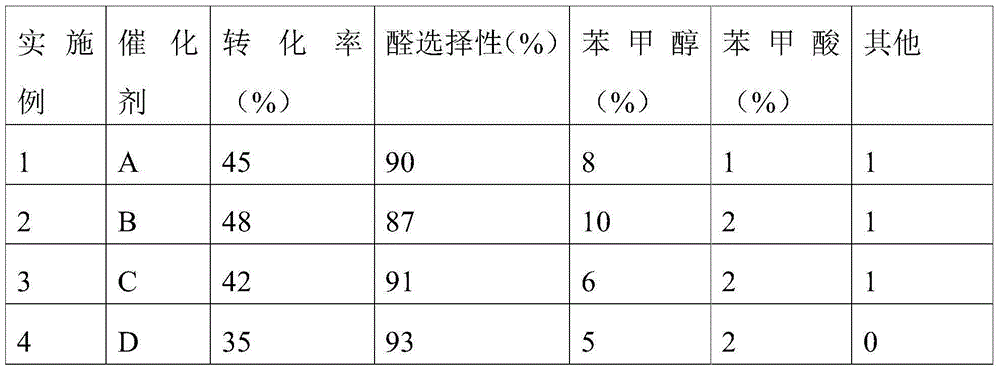

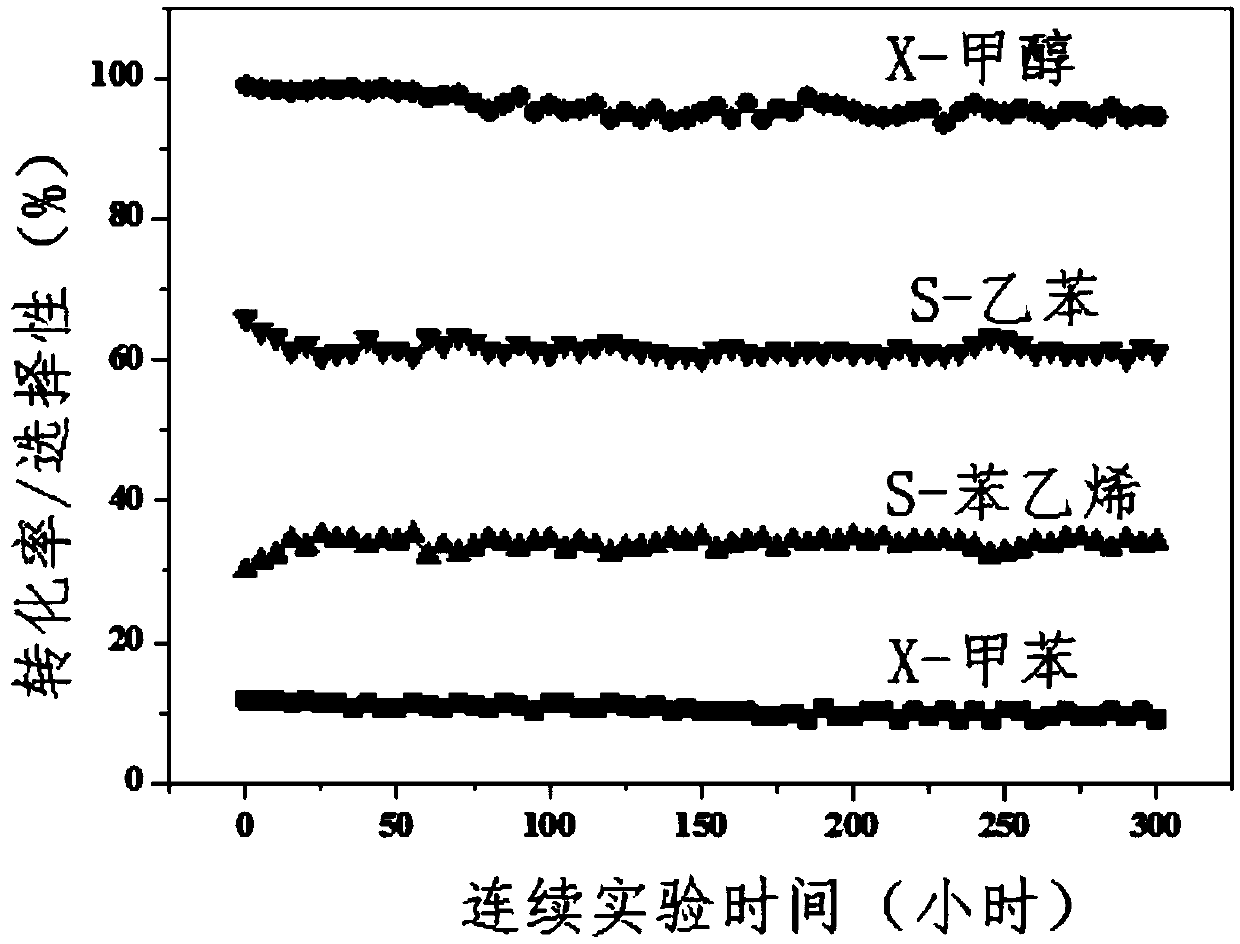

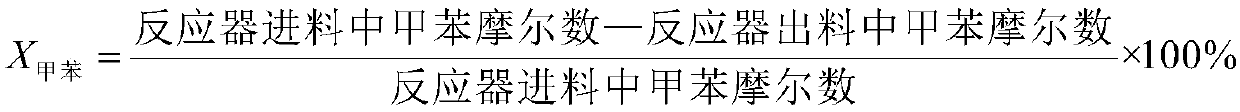

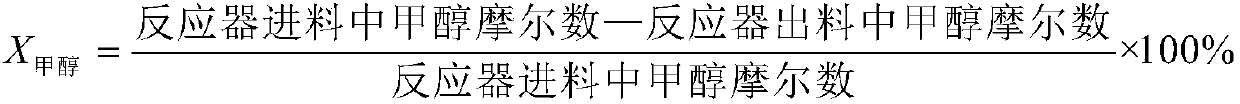

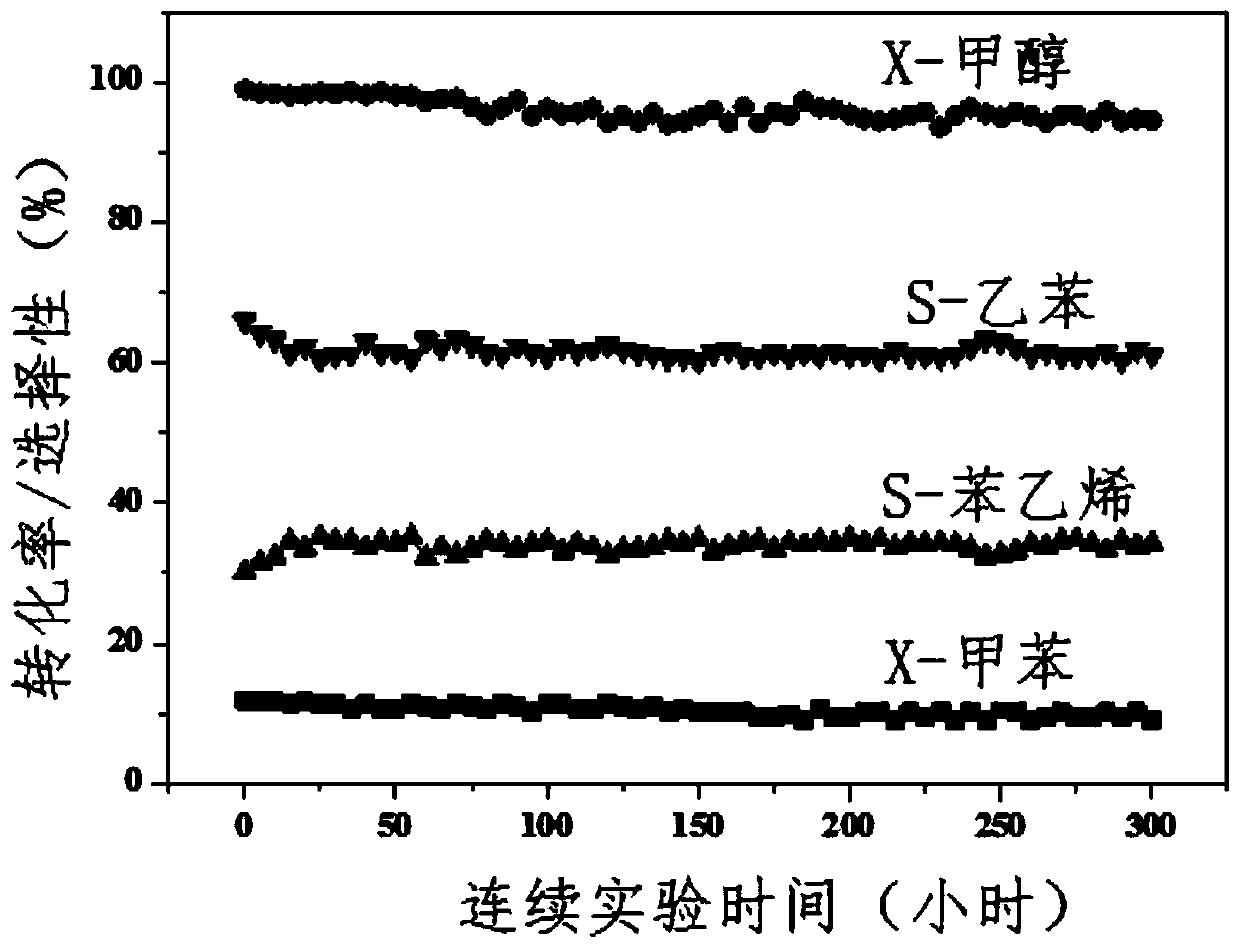

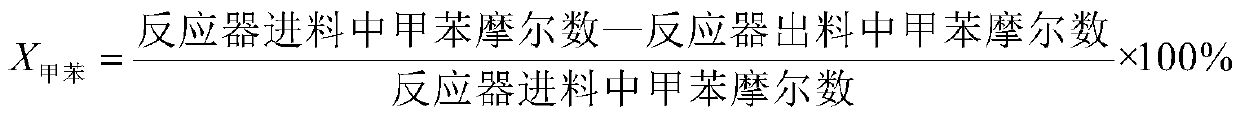

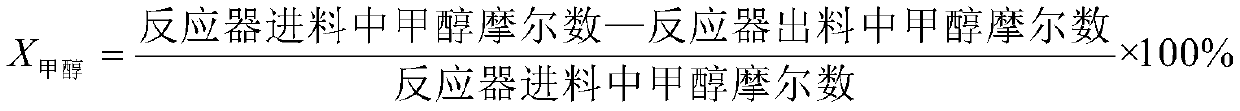

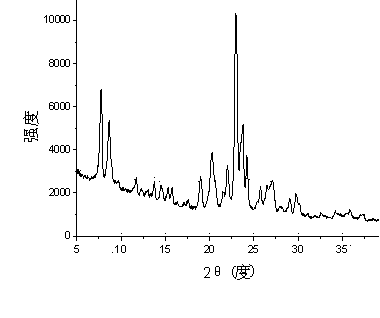

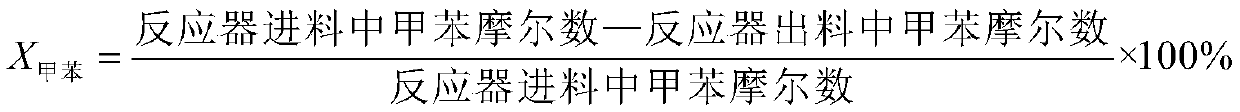

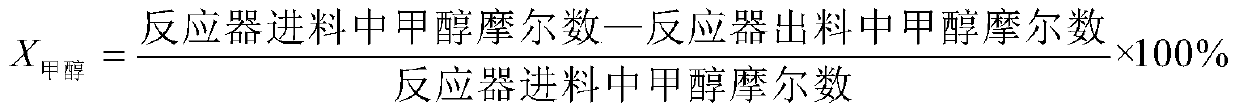

The invention provides a preparation and application of a high-performance toluene side-chain alkylation catalyst. The catalyst can greatly improve the conversion rate of toluene while keeping a high selectivity of styrene in products in a toluene-methanol side chain alkylation reaction system, and is characterized by comprising a basic molecular sieve and a supported alkali metal oxide, wherein the basic molecular sieve is an alkali metal molecular sieve with an FAU structure; the supported alkali metal oxide comprises a carrier and the alkali metal oxide supported on the carrier. The invention further provides the application of the catalyst to preparation of the styrene by toluene and methanol and reaction of ethylbenzene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing ethylbenzene and styrene by side-chain alkylation reaction of toluene with methanol

ActiveCN102372549AHigh selectivityHigh toluene conversionHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferSide chain

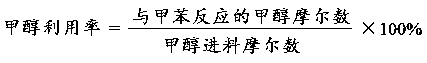

The invention relates to a method for preparing ethylbenzene and styrene by side-chain alkylation reaction of toluene with methanol and mainly solves the problems of low toluene conversion rate and low selectivity of ethylbenzene and styrene in the prior art. According to the invention, toluene and methanol are used as raw materials to contact with a catalyst so as to generate ethylbenzene and styrene while the reaction temperature is 200-600 DEG C, the reaction pressure is 0-0.5MPa, weight space velocity of the raw materials is 0.5-10h<-1>. Sylvite is used for ion exchange before using the catalyst used in the reaction. The technical scheme greatly solves the problems and can be used in the industrial production of ethylbenzene and styrene by side-chain alkylation reaction of toluene with methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

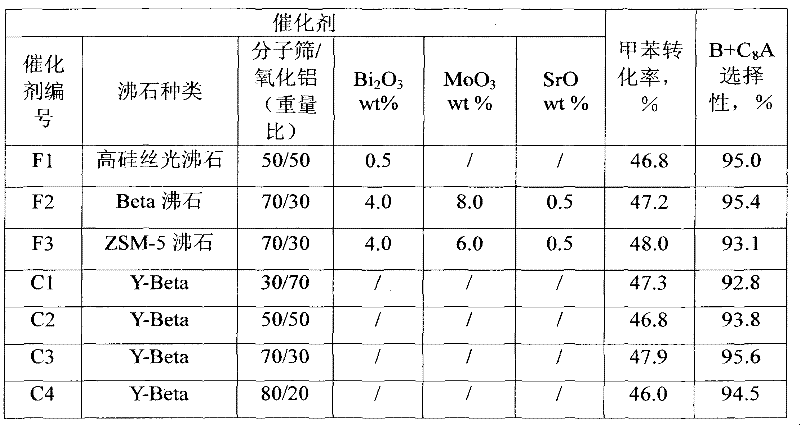

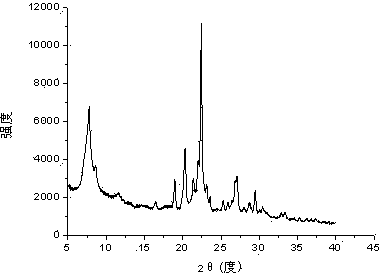

EU-1/ZSM-5 composite molecular sieve, and catalyst for toluene disproportionation and transalkylation and application of catalyst

ActiveCN102909061AFacilitated DiffusionHigh selectivityMolecular sieve catalystsHydrocarbonsMolecular sieveBenzene

The present invention discloses an EU-1 / ZSM-5 composite molecular sieve and a toluene disproportionation and transalkylation catalyst and application of the catalyst. In the EU-1 / ZSM-5 composite molecular sieve, a ZSM-5 molecular sieve is embedded around a EU-1 molecular sieve, the EU-1 molecular sieve accounts for 30% to 70% weight percent of the composite molecular sieve, and the molar ratio of silica / alumina is 30 to 50. The toluene disproportionation and transfer catalyst includes the composite molecular sieve. The composite molecular sieve-containing toluene disproportionation and transalkylation catalyst of the present invention has excellent performance in use without carrying metal components, and has relatively high toluene conversion rate, and benzene and xylene (B + C8A) selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

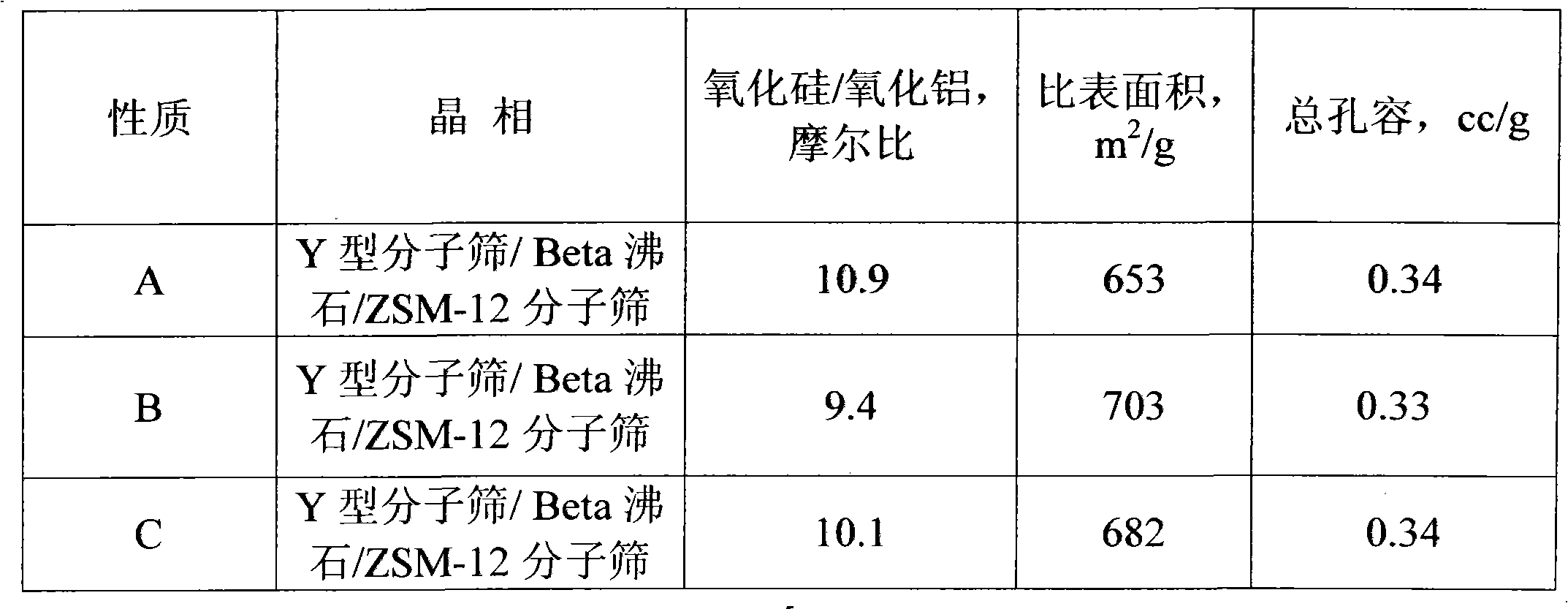

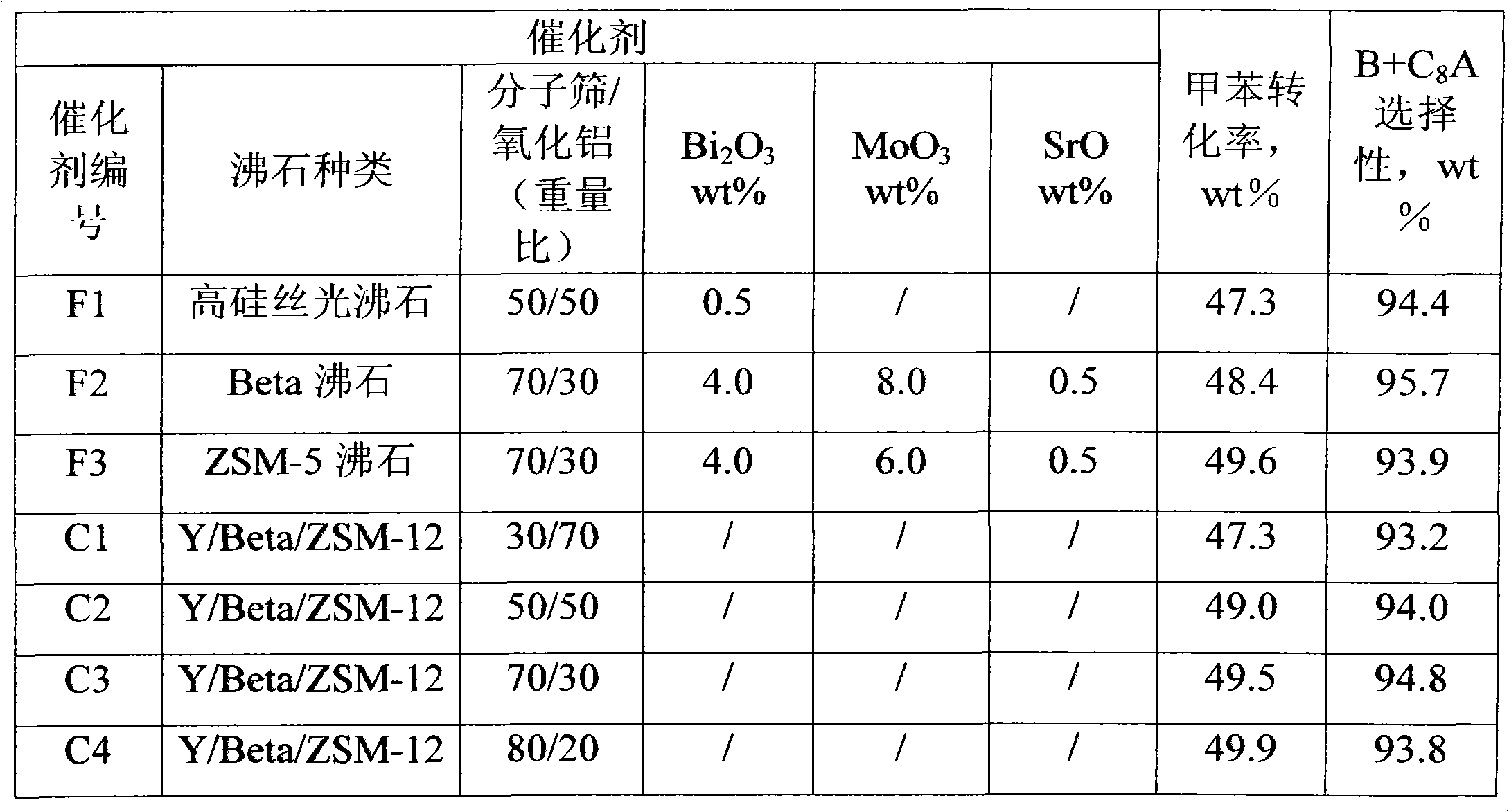

Toluene disproportionation and transalkylation catalyst and preparation method thereof

The invention discloses a toluene disproportionation and transalkylation catalyst and a preparation method thereof. The catalyst consists of hydrogen type Y / Beta / ZSM-12 composite zeolite and inorganic refractory oxide, wherein the content of the composite zeolite is 10wt%-90wt%, and the silica alumina ratio of the composite zeolite is 5-30. The preparation method of the catalyst comprises the following steps: kneading hydrogen type Y / Beta / ZSM-12 composite zeolite, inorganic refractory oxide, peptizing acid, extrusion assistant and the like for shaping, drying, and roasting to obtain the catalyst. The preparation method of the toluene disproportionation and transalkylation catalyst is easy, the cost of the catalyst is low, the toluene conversion and B+C8A selectivity are higher, and the stability is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

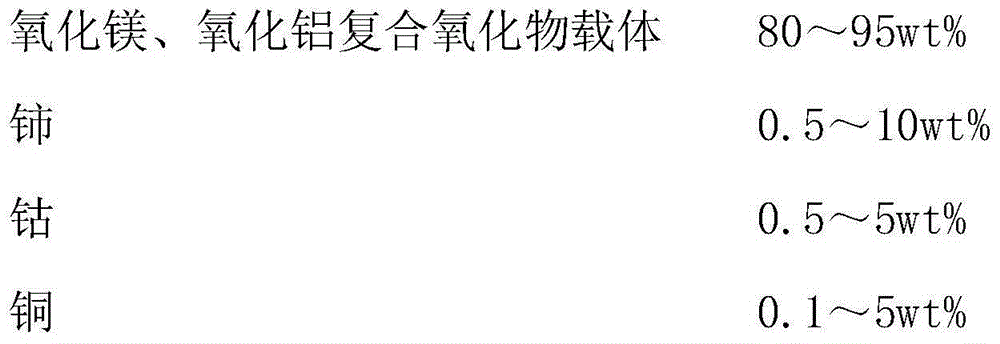

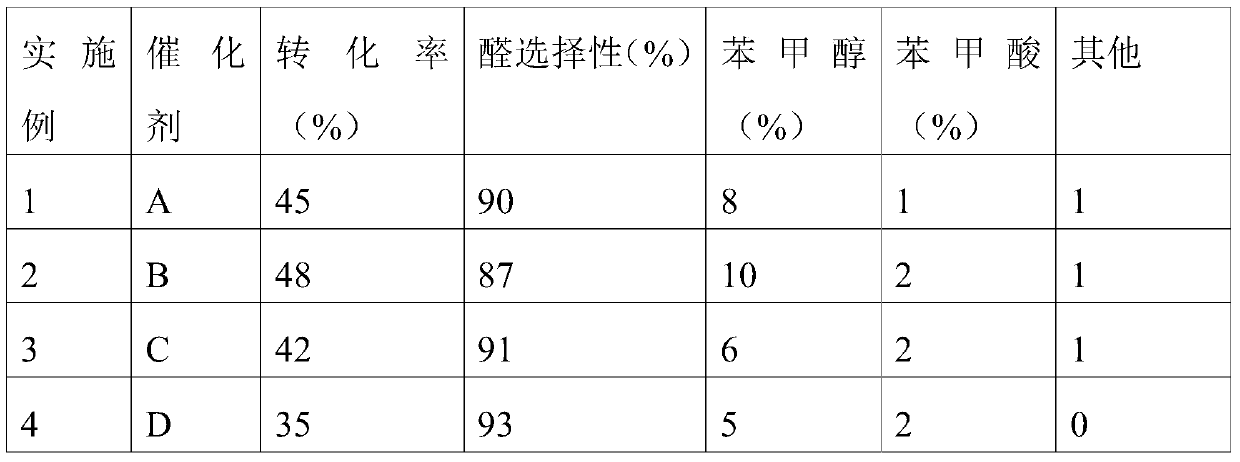

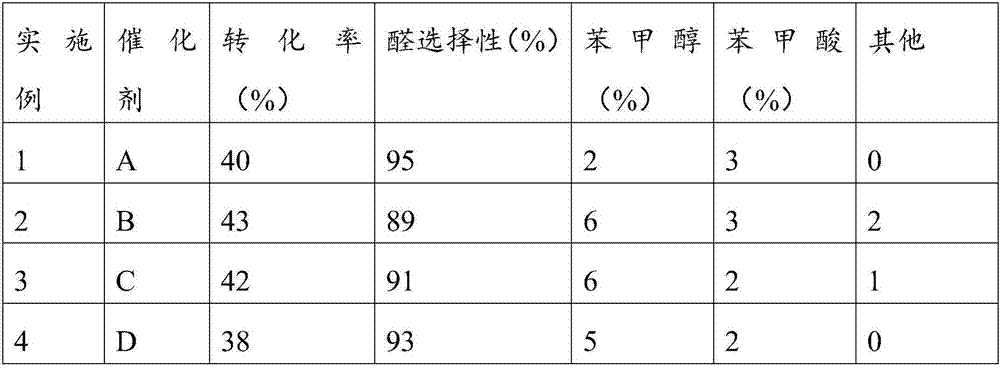

Catalyst for catalyzing direct oxidation of toluene to prepare benzaldehyde and preparation method thereof

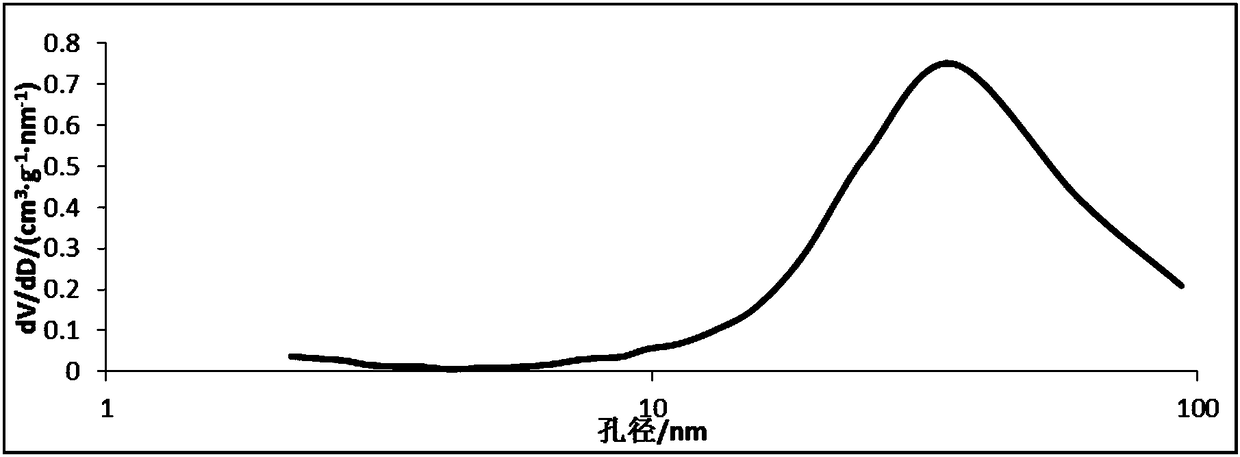

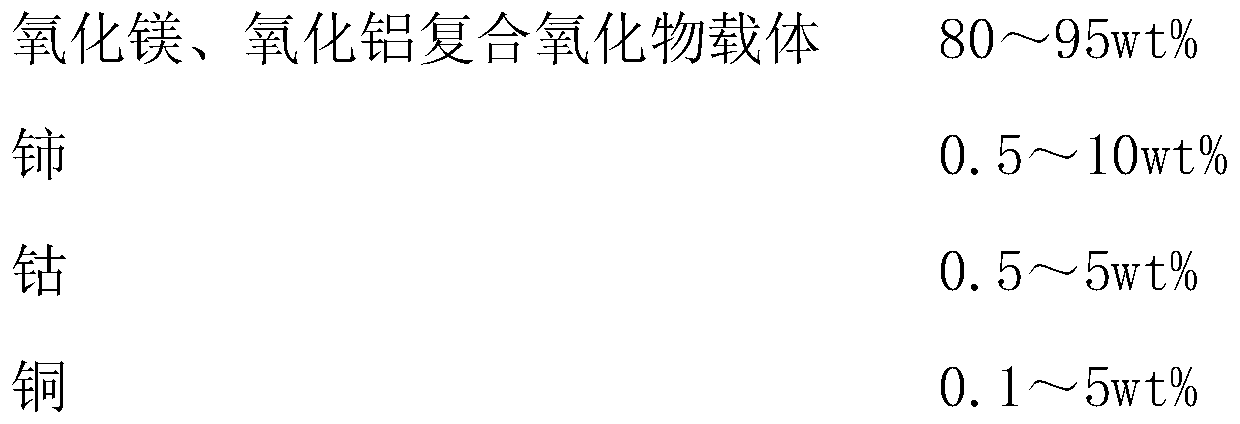

ActiveCN105126857AHigh toluene conversionExcellent performanceOrganic compound preparationCarbonyl compound preparationBenzaldehydeMagnesium

The invention relates to a catalyst for catalyzing direct oxidation of toluene to prepare benzaldehyde and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 85 to 90 wt% of magnesium oxide and alumina composite oxide carrier; 0.5 to 10 wt% of cerium, 0.5 to 5 wt% of cobalt, 0.1 to 5 wt% of copper, and 0.5 to 2 wt% of nickel, wherein the mole ratio of magnesium oxide to alumina is 1-2. The catalyst takes a mixture of magnesium oxide and alumina as the carrier, can directly catalyze the oxidation of toluene to prepare benzaldehyde, and has the advantages of high toluene conversion rate, high benzaldehyde selectivity, high reaction stability, excellent performance, and mild reaction conditions. Moreover, the reaction product and the reactants are in two phases, and thus separation and purification become easier.

Owner:YANCHENG CITY CHUNZHU AROMA

Catalyst composition containing modified ZSM-11 zeolite and application of catalyst composition

ActiveCN103041845AImprove conversion rateReduce the difficulty of operationMolecular sieve catalystsHydrocarbonsPtru catalystAlkali metal oxide

The invention relates to a catalyst composition containing modified ZSM-11 zeolite and an application of the catalyst composition. The catalyst composition comprises the following components of: 30-85 percent of ZSM-11 zeolite, 10-60 percent of binding agent, 0.1-10 percent of alkali metal oxide, 1-20 percent of ZSM-11 zeolite modified additive SiO2 and 1-20 percent of ZSM-11 zeolite modified additive alkali metal oxide. The catalyst composition disclosed by the invention is used in a methylbenzene alkylation process for synthesizing p-methyl methylbenzene from methylbenzene and ethylene and is favorable in catalytic reaction effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Toluene and methanol and/or dimethyl ether alkylation reaction catalyst and preparation method thereof

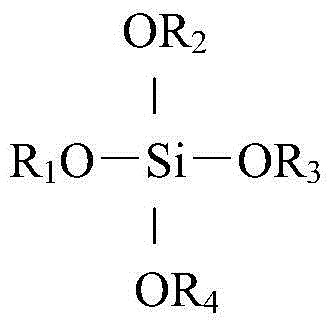

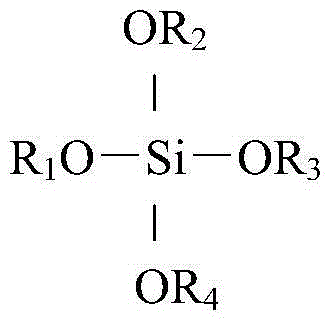

ActiveCN105772061AInhibition of toluene disproportionation reactionHigh toluene conversionMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveSiloxane

The invention provides a toluene and methanol and / or dimethyl ether alkylation reaction catalyst and a preparation method thereof. The outer surface acid site of the catalyst is passivated through modification, and the inner surface acid site of the catalyst is retained. The preparation method of the catalyst comprises the following steps: a hydrogen-type molecular sieve with an MFI topological structure is subjected to element modification, such that the acid site is modified; the sample is dried and roasted, and is subjected to pre-absorption in saturated water vapor; the sample is then subjected to absorption in saturated ethanol vapor; the sample is impregnated in a siloxane-based agent, such that the siloxane-based agent is only absorbed on the outer surface of the molecular sieve; and drying and roasting are carried out, such that a high-activity selective catalyst is obtained. When the catalyst is applied in a toluene and methanol and / or dimethyl ether alkylation reaction, toluene conversion ate can be effectively improved, and the generation of light hydrocarbon components can be reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for alkylation of toluene and methanol and preparation method thereof

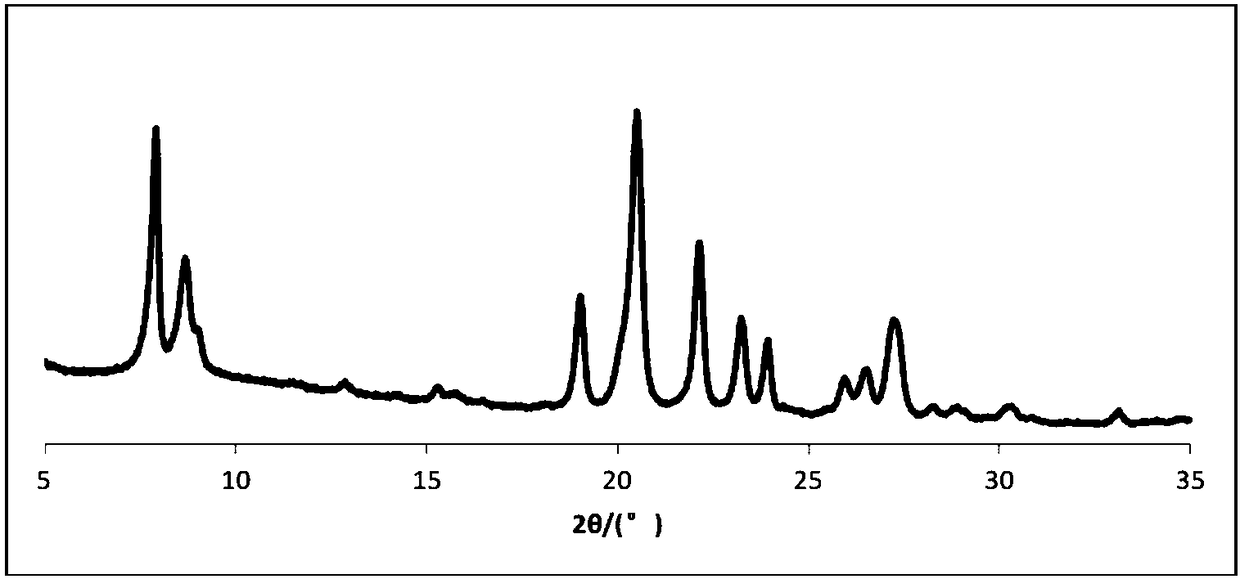

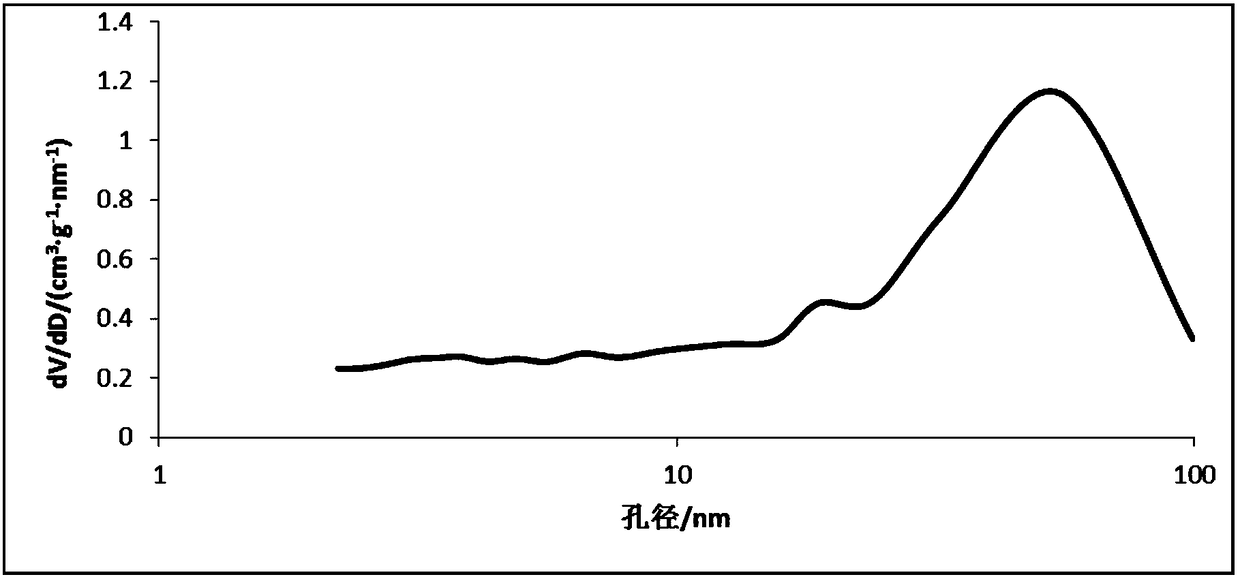

ActiveCN108786908AHigh toluene conversionHigh selectivityMolecular sieve catalystsMolecular sieve catalystMolecular sieveChemistry

Disclosed is a catalyst for alkylation of toluene and methanol. The catalyst includes a carrier and the following active components calculated on the basis of the carrier, by mass: 0.5-10.0% of B, and4-18% of Mg. The carrier includes, by mass, 5-90% of an EU-1 molecular sieve and 10-95% of a binder, wherein the pore volume of the EU-1 molecular sieve is 0.30-0.70 ml / g and the specific surface area is 360-500 m2 / g. The catalyst is used for alkylation reactions of toluene and methanol. The catalyst is high in toluene conversion rate and has high p-xylene selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing benzaldehyde by direct oxidation of toluene and preparation method thereof

ActiveCN105126857BHigh selectivityImprove reaction stabilityOrganic compound preparationCarbonyl compound preparationBenzaldehydeCerium

The invention relates to a catalyst for catalyzing direct oxidation of toluene to prepare benzaldehyde and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 85 to 90 wt% of magnesium oxide and alumina composite oxide carrier; 0.5 to 10 wt% of cerium, 0.5 to 5 wt% of cobalt, 0.1 to 5 wt% of copper, and 0.5 to 2 wt% of nickel, wherein the mole ratio of magnesium oxide to alumina is 1-2. The catalyst takes a mixture of magnesium oxide and alumina as the carrier, can directly catalyze the oxidation of toluene to prepare benzaldehyde, and has the advantages of high toluene conversion rate, high benzaldehyde selectivity, high reaction stability, excellent performance, and mild reaction conditions. Moreover, the reaction product and the reactants are in two phases, and thus separation and purification become easier.

Owner:YANCHENG CITY CHUNZHU AROMA

Catalyst for toluene disproportionation and transalkylation and application thereof

ActiveCN101898154AEasy to prepareLow costMolecular sieve catalystsHydrocarbonsFixed bedDisproportionation

The invention discloses a catalyst for toluene disproportionation and transalkylation, comprising a hydrogen type Y-Beta composite molecular sieve and an inorganic refractory oxide, wherein the content of the hydrogen type Y-Beta composite molecular sieve in the catalyst is 10 wt%-90 wt%. The catalyst for toluene disproportionation and transalkylation is applied to the process of preparing benzene and dimethylbenzene by using toluene and C9 aromatic hydrocarbon as raw materials; by adopting a fixed bed process and appropriate process conditions, higher toluene transforming rate and B+C8A selectivity and favorable stability can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

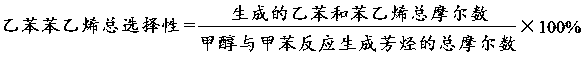

Catalyst for side-chain alkylation reaction of toluene methanol, and preparation method of styrene

ActiveCN109529910AImprove stabilityGuaranteed spatial structureMolecular sieve catalystsMolecular sieve catalystSide chainDehydrogenation

The invention discloses a catalyst for a side-chain alkylation reaction of toluene methanol, and a preparation method of styrene. The catalyst comprises: an ordered mesoporous molecular sieve catalystand a methanol oxygen-free dehydrogenation catalyst; and the ordered mesoporous molecular sieve catalyst is doped with alkali metal ions. The catalyst utilizes the better dehydrogenation performanceof the methanol oxygen-free dehydrogenation catalyst to produce a true alkylation reagent formaldehyde, and on the other hand, the alkali metal ion-modified mesoporous molecular sieve catalyst has excellent side-chain alkylation performance, the products styrene and ethylbenzene are obtained, and higher toluene conversion and styrene ethylbenzene selectivity can be obtained. The invention also provides the preparation method of styrene by using the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of method that benzyl peroxide is prepared by toluene liquid-phase air oxidation method

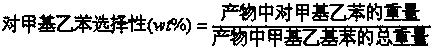

ActiveCN106831521BGuaranteed oxygen contentAchieve the purpose of obtainingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsToluene oxidationReaction temperature

The invention discloses a method for preparing benzyl peroxide by adopting a toluene liquid-phase air oxidation method. Under the synergistic effect of a catalyst, an initiator and an assistant, toluene and oxygen in the air perform oxidizing reaction to generate the benzyl peroxide, the balance of reaction temperature is ensured by adopting an external circulated cooling mode, pressure balance in a toluene oxidation reactor is controlled according to the discharge amount of high-temperature compressed tail gas or nitrogen or reaction tail gas led from the upper portion of the reactor, the reaction process is full-automatically controlled, and safe, stable and continuous reaction is ensured. The oxygen content in the reaction tail gas is ensured by controlling the high-temperature compressed tail gas or nitrogen led from the lower portion of the reactor and reaction conditions, and higher toluene conversion rate is ensured. The product benzyl peroxide can serve as a raw production material of benzene-alcohol, aromatic aldehyde, aromatic acid and benzyl ester, and the method is a green and environment-friendly no-chloride involved process.

Owner:湖北科林博伦新材料有限公司

Catalyst for side-chain alkylation of toluene and methanol, method for preparing styrene

ActiveCN109529910BImprove stabilityGuaranteed acidity and alkalinityMolecular sieve catalystsMolecular sieve catalystPolymer sciencePtru catalyst

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

EU-1/ZSM-5 composite molecular sieve, and catalyst for toluene disproportionation and transalkylation and application of catalyst

ActiveCN102909061BFacilitated DiffusionHigh selectivityMolecular sieve catalystsHydrocarbonsMolecular sieveBenzene

The present invention discloses an EU-1 / ZSM-5 composite molecular sieve and a toluene disproportionation and transalkylation catalyst and application of the catalyst. In the EU-1 / ZSM-5 composite molecular sieve, a ZSM-5 molecular sieve is embedded around a EU-1 molecular sieve, the EU-1 molecular sieve accounts for 30% to 70% weight percent of the composite molecular sieve, and the molar ratio of silica / alumina is 30 to 50. The toluene disproportionation and transfer catalyst includes the composite molecular sieve. The composite molecular sieve-containing toluene disproportionation and transalkylation catalyst of the present invention has excellent performance in use without carrying metal components, and has relatively high toluene conversion rate, and benzene and xylene (B + C8A) selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst of toluene disproportionation and alkyl transference, and preparation method and application thereof

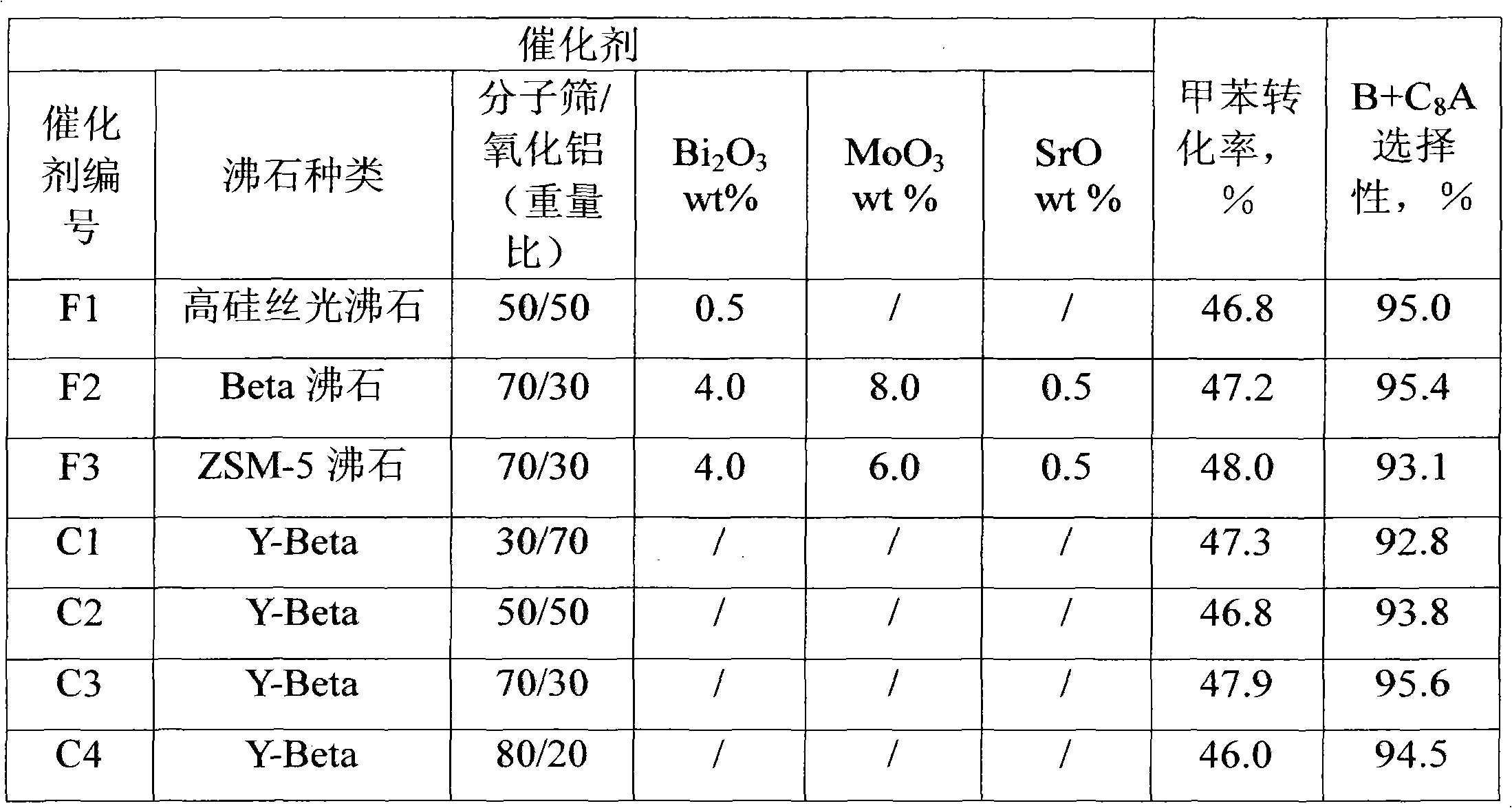

ActiveCN102909066AFacilitated DiffusionHigh selectivityMolecular sieve catalystsHydrocarbonsCopper oxideDisproportionation

The invention discloses a catalyst of toluene disproportionation and alkyl transference, and a preparation method and an application thereof. The catalyst comprises 10 wt%-90 wt% of hydrogen Eu-1 / Beta composite molecular sieve, 5 wt%-85 wt% of an inorganic refractory oxide, 0.1 wt%-10 wt% of bismuth oxide, and 0.1 wt%-10 wt% of one or more of molybdenum oxide, silver oxide, zirconium oxide, strontium oxide, lanthanum oxide, copper oxide and rhenium oxide. The composite molecular sieve catalyst of toluene disproportionation and alkyl transference has good usage performance without loading metal components, and has relatively high toluene conversion rate and relatively high selectivity of benzene and dimethylbenzene (B+C8A).

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of catalyst and its application

ActiveCN111215126BHigh toluene conversionHigh selectivityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

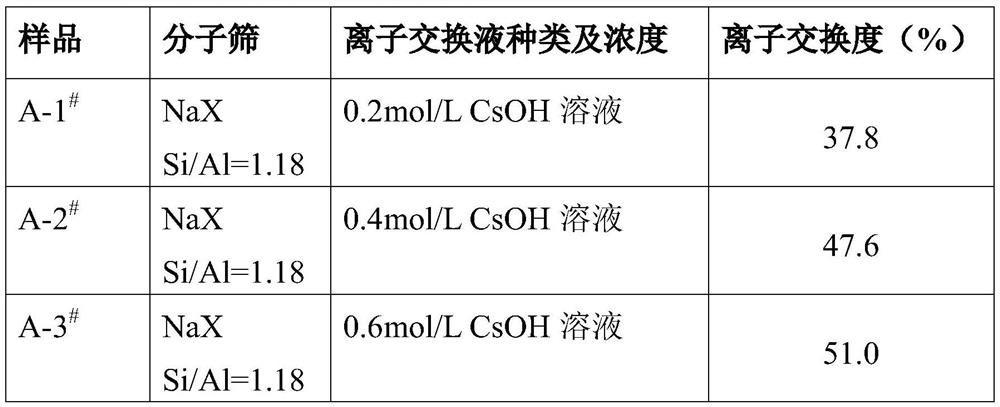

The invention discloses a method for preparing a toluene methanol side chain alkylation catalyst. The alkali metal type molecular sieve is ion-exchanged in an alkali metal-containing solution, calcined I, ball milled, and calcined II to obtain the catalyst. The prepared catalyst can greatly increase the conversion rate of toluene, and at the same time, can keep the total selectivity of ethylbenzene and styrene in the product higher.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Toluene Methanol Side Chain Alkylation Method

ActiveCN104557422BImprove stabilityHigh toluene conversionMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationRare-earth elementSide chain

The invention relates to a side-chain alkylation method of toluene methanol, which mainly solves the problems of rapid catalyst deactivation and poor stability in the prior art. The present invention uses toluene and methanol as raw materials, under the condition that the reaction temperature is 200-600°C, the reaction pressure is 0-0.5 MPa, and the weight space velocity of the raw materials is 0.5-10 hours-1, the raw materials are contacted with the catalyst, and the reaction produces Ethylbenzene and styrene; the molar ratio of toluene to methanol in the raw material is 0.1-10; the catalyst includes the following components in weight percentage: a) 98-99.5% alkali metal ion-exchanged X molecular sieve; b) 0.5- The technical solution of 2% rare earth elements solves this problem well, and can be used in the industrial production of ethylbenzene and styrene by side-chain alkylation of toluene and methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

EU-1/Beta composite molecular sieve, and catalyst for toluene disproportionation and transalkylation and application of catalyst

ActiveCN102909063BFacilitated DiffusionHigh selectivityMolecular sieve catalystsHydrocarbonsMolecular sieveDisproportionation

The invention discloses an EU-1 / Beta composite molecular sieve, and a catalyst for toluene disproportionation and transalkylation and the application of the catalyst. The EU-1 / Beta composite molecular sieve has crystal phases of an EU-1 molecular sieve and a Beta molecular sieve. The structure of the composite molecular sieve is that the Beta molecular sieve tightly wraps around the EU-1 molecular sieve, wherein the EU-1 molecular sieve accounts for 30% to 70% weight percent of the composite molecular sieve. The catalyst for toluene disproportionation and transalkylation of the invention includes the above EU-1 / Beta composite molecular sieve, and the EU-1 / Beta composite molecular sieve accounts for 40% to 95% weight percent of the catalyst. The composite molecular sieve-containing catalyst for toluene disproportionation and transalkylation of the invention has excellent performance in use without carrying metal components, and has relatively high toluene conversion rate, and benzene and xylene (B + C8A) selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

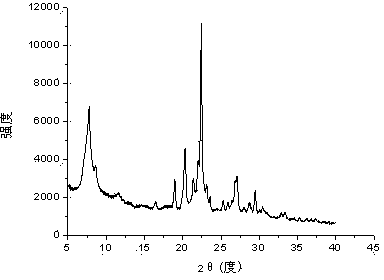

Toluene oxidation catalyst and preparation method thereof

InactiveCN107497445AHigh selectivityImprove reaction stabilityOrganic compound preparationHeterogenous catalyst chemical elementsBenzaldehydeToluene oxidation

The invention relates to a toluene oxidation catalyst and a preparation method thereof. The toluene oxidation catalyst comprises the following components: 85-90wt% of zinc oxide and aluminum oxide compounded oxide carrier, 0.5-10wt% of cerium, 2-6wt% of vanadium, 0.1-5wt% of tin and 1-3.5wt% of copper, wherein the mole ratio of zinc oxide to aluminum oxide is 1-2. The toluene oxidation catalyst provided by the invention takes the mixture of zinc oxide and aluminum oxide as a carrier; the catalyst has high methylbenzene conversion rate, benzaldehyde selectivity and reaction stability, excellent performance and mild reaction condition; the catalyst exits in the two phases of reactant and product and can be easily separated and purified.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

A kind of toluene disproportionation and transalkylation catalyst and its application

ActiveCN101898154BEasy to prepareLow costMolecular sieve catalystsHydrocarbonsMolecular sieveBenzene

The invention discloses a catalyst for toluene disproportionation and transalkylation, comprising a hydrogen type Y-Beta composite molecular sieve and an inorganic refractory oxide, wherein the content of the hydrogen type Y-Beta composite molecular sieve in the catalyst is 10 wt%-90 wt%. The catalyst for toluene disproportionation and transalkylation is applied to the process of preparing benzene and dimethylbenzene by using toluene and C9 aromatic hydrocarbon as raw materials; by adopting a fixed bed process and appropriate process conditions, higher toluene transforming rate and B+C8A selectivity and favorable stability can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

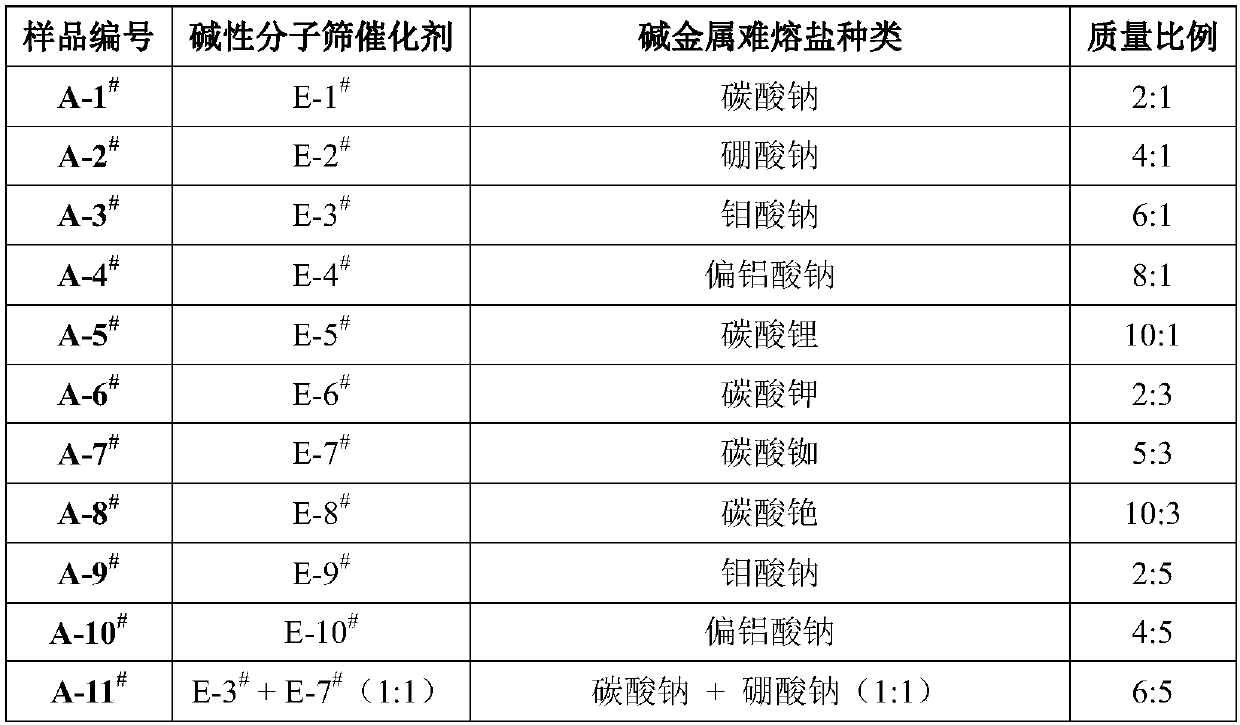

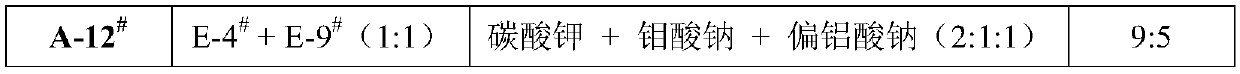

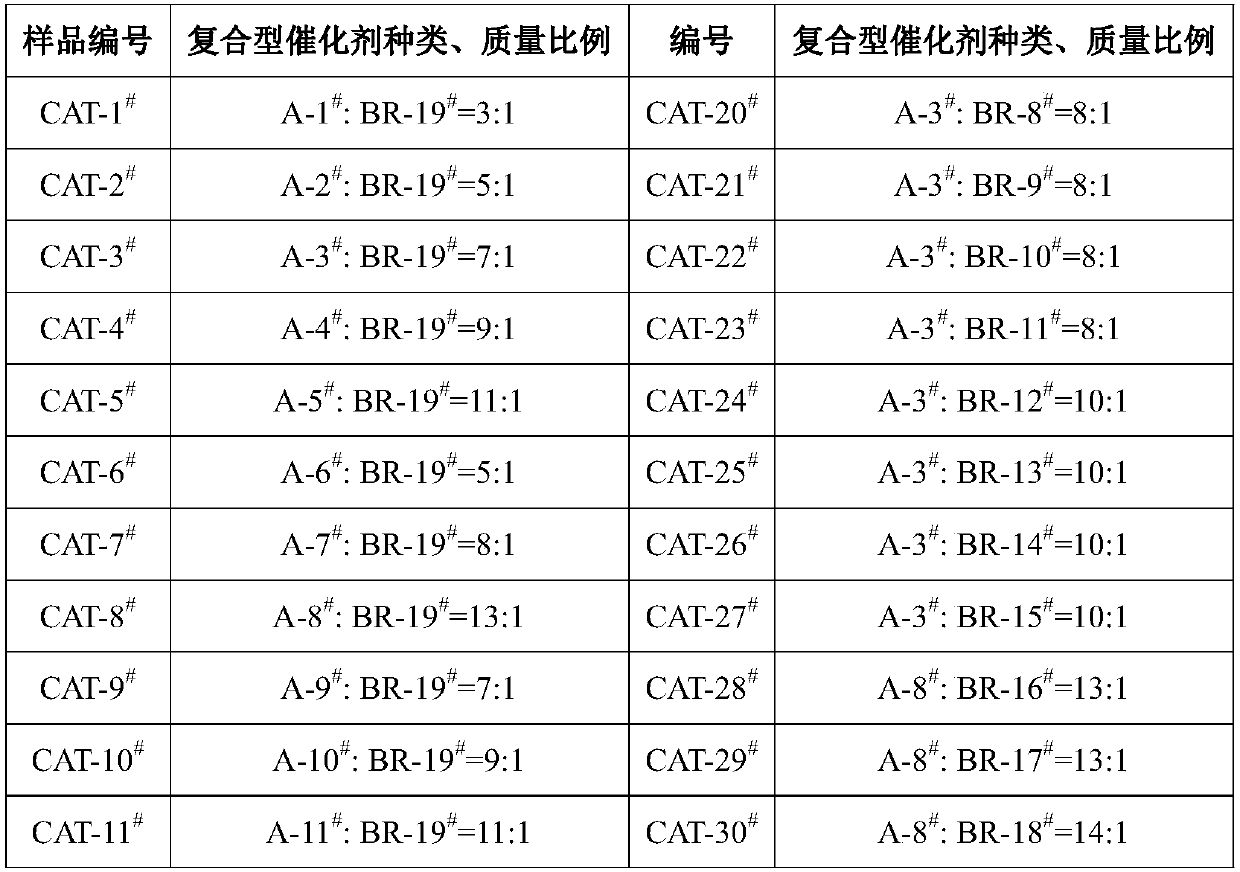

Composite type catalyst, preparation method of composite type catalyst and application in methylbenzene

ActiveCN109675611AHigh toluene conversionImprove stabilityMolecular sieve catalystsMolecular sieve catalystMolecular sieveToluene

The invention discloses a composite type catalyst, a preparation method of the composite type catalyst and application in methylbenzene. The composite type catalyst is prepared from alkaline molecularsieve based catalysts, alkali metal refractory salt and a boracic type catalyst; and the alkali metal refractory salt is loaded on the alkaline molecular sieve based catalysts. The composite type catalyst is used for methylbenzene and the process of preparing styrene by using methyl alcohol, and the methylbenzene percent conversion, methyl alcohol use ratio and styrene yield can be effectively improved. On the other hand, the invention further provides the preparation method and application of the composite type catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing catalyst of para xylene through methylation of toluene

ActiveCN100408180CHigh selectivityHigh toluene conversionMolecular sieve catalystsHydrocarbonsEtherMethylation

A catalyst for methylating toluene to prepare xylene with high selectivity and low requirement to environment features that the combined organic amine-ether template is used to prepare ZSM-5 molecular sieve, and said ZSM-5 molecular sieve is then modified by organosilicon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation and application of a high-performance toluene side chain alkylation catalyst

ActiveCN106179459BHigh selectivityHigh toluene conversionMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkyl transfer

The invention provides the preparation and application of a high-performance toluene side chain alkylation catalyst. In the toluene methanol side chain alkylation reaction system, the catalyst can greatly increase the conversion rate of toluene while maintaining the high selectivity of styrene in the product. The catalyst is characterized in that it includes a basic molecular sieve and a loaded alkali metal oxide; wherein the basic molecular sieve is an alkali metal molecular sieve with a FAU structure; the loaded alkali metal oxide includes a carrier and a loaded alkali metal oxide. Alkali metal oxides on supports. The invention also provides the application of the catalyst in the reaction of toluene and methanol to produce styrene and ethylbenzene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Composite catalyst for producing styrene by side-chain alkylation of toluene and methanol, and method for preparing styrene

ActiveCN109675610BControl decompositionHigh selectivityMolecular sieve catalystsMolecular sieve catalystMolecular sievePolymer science

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst composition containing modified ZSM-11 zeolite and application of catalyst composition

ActiveCN103041845BImprove conversion rateReduce the difficulty of operationMolecular sieve catalystsHydrocarbonsPtru catalystAlkali metal oxide

The invention relates to a catalyst composition containing modified ZSM-11 zeolite and its application. The catalyst composition has the following composition: ZSM-11 zeolite 30%~85%, binder 10%~60%, alkali metal oxide 0.1%~10%, ZSM-11 zeolite modification additive silica 1%~ 20%, ZSM-11 zeolite modification additive alkaline earth metal oxide 1%~20%. The catalyst composition of the invention is used in the toluene alkylation process for synthesizing p-methylethylbenzene from toluene and ethylene, and has good catalytic reaction effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkylation catalyst containing modified zsm-11 zeolite and its application

ActiveCN103041846BImprove conversion rateReduce the difficulty of operationMolecular sieve catalystsHydrocarbonsPtru catalystAlkali metal oxide

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing benzyl peroxide by adopting methylbenzene liquid-phase air oxidation method

ActiveCN106831521AGuaranteed oxygen contentAchieve the purpose of obtainingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsToluene oxidationReaction temperature

The invention discloses a method for preparing benzyl peroxide by adopting a toluene liquid-phase air oxidation method. Under the synergistic effect of a catalyst, an initiator and an assistant, toluene and oxygen in the air perform oxidizing reaction to generate the benzyl peroxide, the balance of reaction temperature is ensured by adopting an external circulated cooling mode, pressure balance in a toluene oxidation reactor is controlled according to the discharge amount of high-temperature compressed tail gas or nitrogen or reaction tail gas led from the upper portion of the reactor, the reaction process is full-automatically controlled, and safe, stable and continuous reaction is ensured. The oxygen content in the reaction tail gas is ensured by controlling the high-temperature compressed tail gas or nitrogen led from the lower portion of the reactor and reaction conditions, and higher toluene conversion rate is ensured. The product benzyl peroxide can serve as a raw production material of benzene-alcohol, aromatic aldehyde, aromatic acid and benzyl ester, and the method is a green and environment-friendly no-chloride involved process.

Owner:湖北科林博伦新材料有限公司

Toluene disproportionation and transalkylation catalyst and its preparation method and application

ActiveCN103878013BLow costHigh selectivityMolecular sieve catalystsHydrocarbonsXylyleneMolecular sieve

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method that toluene and trioxane prepare styrene

ActiveCN109851459BAvoid hydrogen transfer reactionsSuppress generationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPolymer sciencePtru catalyst

The invention discloses a method for preparing styrene from toluene and paraformaldehyde, which at least includes the following steps: feeding raw material gas containing toluene and paraformaldehyde into a reactor, first contacting with catalyst I to depolymerize the paraformaldehyde into formaldehyde , and the obtained mixed gas is contacted with catalyst II to carry out side chain alkylation reaction to prepare styrene. The method can effectively avoid the hydrogen transfer reaction between styrene and methanol when methanol is used as the alkylating agent by replacing methanol with the formaldehyde produced by the depolymerization of paraformaldehyde as the side chain alkylating agent, and improve the styrene / methanol ratio in the product. It has the characteristics of high conversion rate of toluene and high selectivity of styrene in the product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst of toluene disproportionation and alkyl transference, and preparation method and application thereof

ActiveCN102909066BFacilitated DiffusionHigh selectivityMolecular sieve catalystsHydrocarbonsPtru catalystCopper oxide

The invention discloses a catalyst of toluene disproportionation and alkyl transference, and a preparation method and an application thereof. The catalyst comprises 10 wt%-90 wt% of hydrogen Eu-1 / Beta composite molecular sieve, 5 wt%-85 wt% of an inorganic refractory oxide, 0.1 wt%-10 wt% of bismuth oxide, and 0.1 wt%-10 wt% of one or more of molybdenum oxide, silver oxide, zirconium oxide, strontium oxide, lanthanum oxide, copper oxide and rhenium oxide. The composite molecular sieve catalyst of toluene disproportionation and alkyl transference has good usage performance without loading metal components, and has relatively high toluene conversion rate and relatively high selectivity of benzene and dimethylbenzene (B+C8A).

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com