Catalyst of toluene disproportionation and alkyl transference, and preparation method and application thereof

A technology of alkylation transfer and toluene disproportionation, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., to achieve the effects of prolonging service life, improving selectivity, and reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Synthesis and treatment of embodiment 1 EU-1 / Beta composite molecular sieve

[0043] (1) Synthesis of EU-1 / Beta Composite Molecular Sieve

[0044] Add sodium aluminate, distilled water, and tetraethylammonium hydroxide successively into the beaker, stir evenly, then add EU-1 molecular sieve, stir for 10 minutes, finally add white carbon black, stir for 30 minutes, and then put it into the synthesis kettle.

[0045] The ratio of materials in synthetic materials is:

[0046] EU-1 / SiO2 2 (g / g) = 0.35;

[0047] R / SiO 2 (mol / mol) = 0.50;

[0048] SiO 2 / Al 2 o 3 (mol / mol)=112;

[0049] Na 2 O / SiO 2 (mol / mol) = 0.52;

[0050] h 2 O / SiO 2 (mol / mol)=32.

[0051] The synthetic material was heated in an oven at 140°C for 4 days, the obtained product was filtered, washed with distilled water until neutral, dried, and calcined at 550°C for 5 hours to obtain EU-1 / Beta composite molecular sieve.

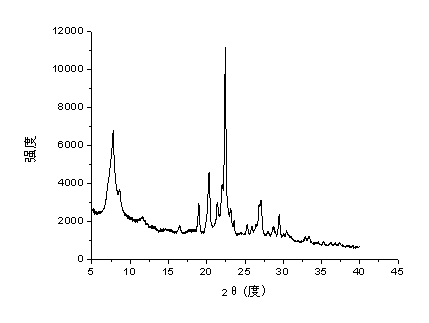

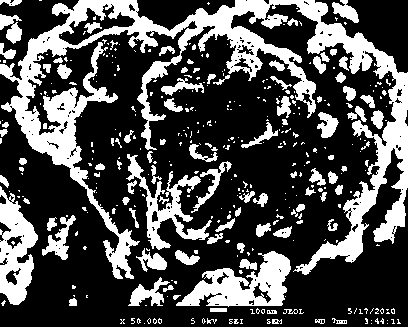

[0052] The XRD spectrum of this EU-1 / Beta composite molecular sieve is a...

Embodiment 2

[0057] The preparation of embodiment 2 carrier

[0058] Take 45 grams of the hydrogen-type EU-1 / Beta composite molecular sieve prepared in Example 1, 145.8 grams of SB powder, and 3.75 grams of scallop powder, mix well, then add 70ml of deionized water and 3.75ml of concentrated nitric acid (66.5wt%) in Fully kneaded on a roller compactor to make it into a paste-like plastic, extruded a cylindrical rod with a diameter of 1.5mm on an extruder, dried at 110°C for 8 hours, and then calcined at 550°C for 4 hours in an air atmosphere to obtain catalyst precursor D1.

[0059] Take 105 grams of hydrogen-type EU-1 / Beta composite molecular sieve prepared in Example 1, 62.5 grams of SB powder, and 3.75 grams of scallop powder, mix well, then add 100ml of deionized water and 3.75ml of concentrated nitric acid (66.5wt%) in the mill Fully knead on the press to make it into a paste-like plastic, extrude a cylindrical rod with a diameter of 1.5mm on the extruder, dry at 110°C for 8 hours, an...

Embodiment 3

[0061] Take the catalyst precursor D1 prepared in Example 2, soak it in the aqueous solution of bismuth nitrate for 24 hours, then dry it at 110° C. for 6 hours, and roast it at 540° C. for 4 hours to obtain the Bi-containing 2 o 3 0.2% by weight of catalyst E1. The catalyst composition and evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com