Catalyst for toluene disproportionation and transalkylation and application thereof

A technology of alkylation transfer and toluene disproportionation, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, organic chemistry, etc., can solve the problems of increasing catalyst preparation steps and increasing catalyst cost, and achieves low catalyst cost, simple preparation method, and high efficiency. Effect of Toluene Conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Synthesis of Y-Beta Composite Molecular Sieve

[0022] Prepared according to Embodiment 4 of Chinese Patent CN1944254A.

[0023] In the first step, add 0.45g of sodium hydroxide, 9.0g of TEABr (tetraethylammonium bromide), 3.0ml of concentrated ammonia water, and 10.1ml of distilled water in sequence, and stir magnetically for 0.5 hours.

[0024] In the second step, 15.0 g of high silica Y zeolite powder and 25 ml of distilled water were added to the above solution, and magnetically stirred for 1 hour.

[0025] In the third step, 12.0ml of silica sol (SiO 2 content 5.80mol / L) into the above solution, then add 1.0ml concentrated ammonia water, mix and stir for 1-2 hours to form a uniform white jelly, put it into a 150ml stainless steel reaction kettle, and crystallize at 140°C for 5 days Take it out, wash until the solution is neutral, and then dry it. The prepared sample was roasted at 550°C for 5h to remove the organic amine tetraethylammonium bromide. The Y-Be...

Embodiment 2

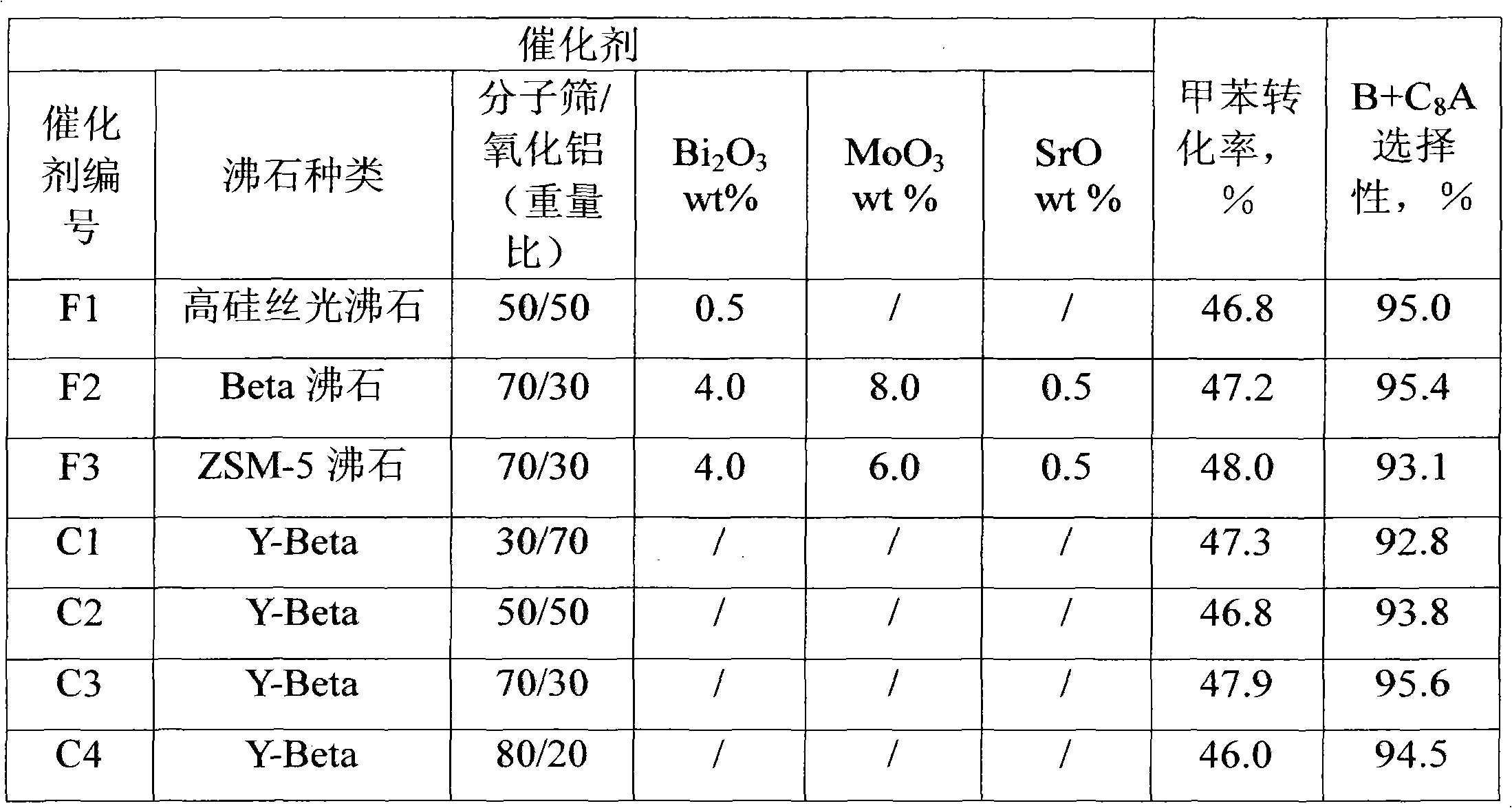

[0033] Get 75 grams of the hydrogen-form Y-Beta composite molecular sieve B prepared in Example 1, 104.2 grams of SB powder, and 3.75 grams of squash powder, mix well, then add 85ml of deionized water and 3.75ml of concentrated nitric acid (66.5w%) in rolling Fully kneaded on the machine to make it into a paste-like plastic, extruded a cylindrical rod with a diameter of 1.5mm on the extruder, dried at 110°C for 8 hours, and then calcined at 550°C for 4 hours in an air atmosphere to obtain catalyst C2. The catalyst composition and evaluation results are shown in Table 2.

Embodiment 3

[0035]Get 105 grams of hydrogen-form Y-Beta composite molecular sieve C prepared in Example 1, 62.5 grams of SB powder, and 3.75 grams of scallop powder, mix well, then add 100ml of deionized water and 3.75ml of concentrated nitric acid (66.5w%) in roller compaction Fully kneaded on the machine to make it into a paste-like plastic, extruded a cylindrical rod with a diameter of 1.5mm on the extruder, dried at 110°C for 8 hours, and then calcined at 550°C for 4 hours in an air atmosphere to obtain catalyst C3. The catalyst composition and evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com