Chemical vapor deposition device

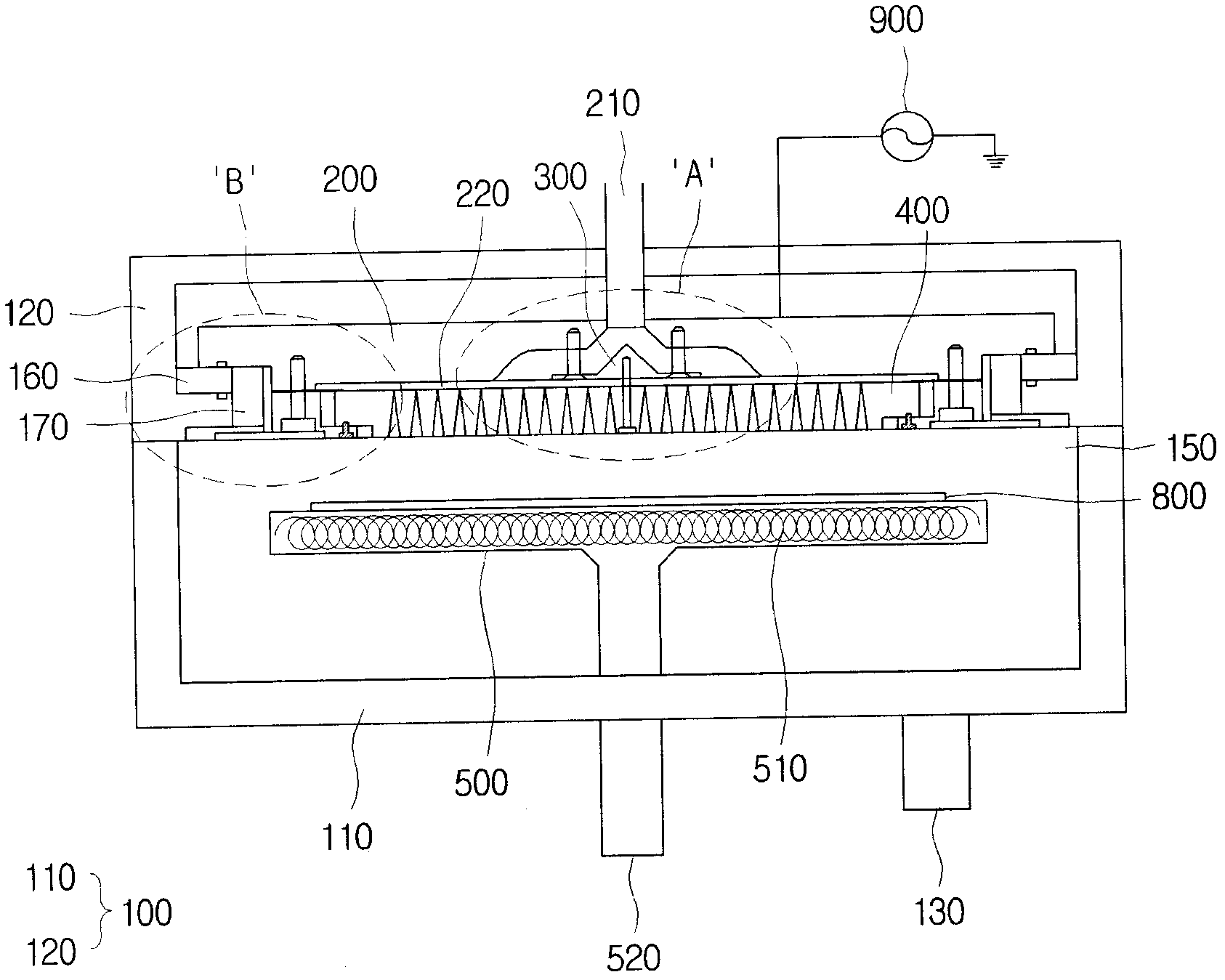

A chemical vapor deposition and gas diffusion technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of uneven distribution density of injected gas, poor process uniformity, etc., to achieve excellent quality, Minimize the effect of thermal expansion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Since the present invention is capable of many changes and embodiments, several specific embodiments will be illustrated and described with reference to the accompanying drawings. However, it is by no means intended to limit the present invention to specific embodiments, but it should be understood that the present invention includes all changes, equivalents, and substitutions encompassed by the concept and scope of the present invention. Throughout the description of the present invention, when it is determined that the description of a certain technology will evade the gist of the present invention, the related detailed description will be omitted.

[0056]Terms such as "first" and "second" may be used to describe various elements, but the above elements should not be limited to the above terms. The above terms are only used to distinguish one element from other elements.

[0057] The terms used in the specification are only used to describe specific embodiments, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com