Method for determining diameter of high-pressure rotary jet grouting pile based on circular free turbulent jet theory

A technology of high-pressure rotary jetting pile and determining method, which is applied in the test of foundation structure, basic structure engineering, construction, etc., can solve the problems of difficult application, high uncertainty, insufficient soil properties and rotary jetting construction parameters, etc. To achieve the effect of accurate judgment and prediction, simple method, and avoidance of unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

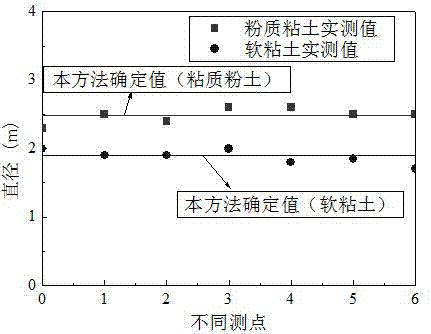

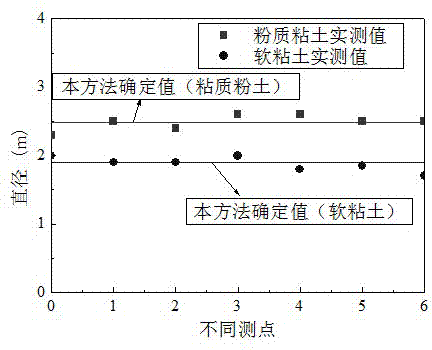

[0047] This example illustrates the method of determining the diameter of the high-pressure jet grouting pile by using high-pressure jet jetting technology to strengthen the formation. There are no operations specifically described in this example. Refer to the method already given in the summary of the invention, and will not repeat them here.

[0048] This embodiment is specifically as follows:

[0049] A high-pressure jet grouting reinforced foundation site is located in Shanghai. The groundwater level in this area floats 1-2m below the ground surface. The designed pile length of the high-pressure jet grouting pile is 20m, the pile top is 2m below the ground surface, and the pile bottom is 22m below the ground surface.

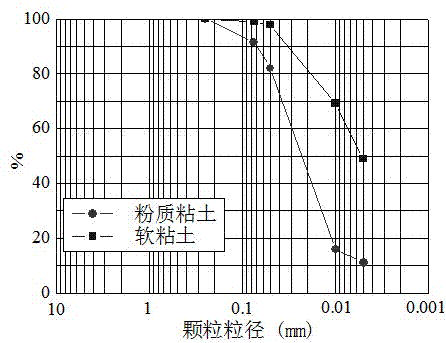

[0050] The first step is to clarify the geological conditions of the site: the top layer (0.0-1.6 m) is the backfill soil layer; the lower layer (1.6-15.5 m) is the clayey silt layer; the lower layer (15.5-25.2 m) is the soft clay layer , and the nex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com