Self-seal hard dual-valve seat of balance-type valve core

A self-sealing, double-valve-seat technology, used in lift valves, valve devices, engine components, etc., can solve the problems of shortened life of the regulating valve, large output force, and wear of the sealing surface, so as to reduce the output force and wear, reduce The friction area, the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

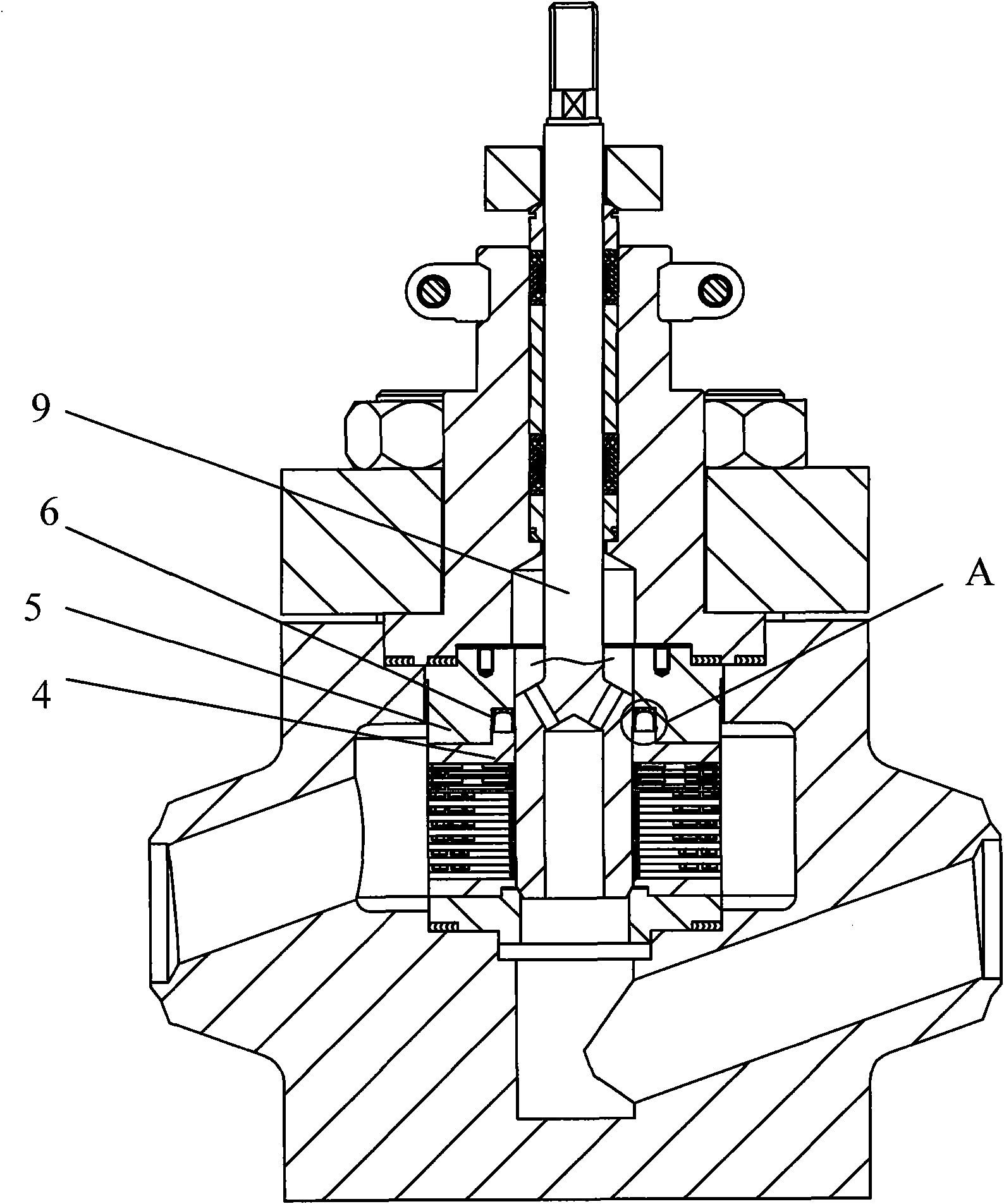

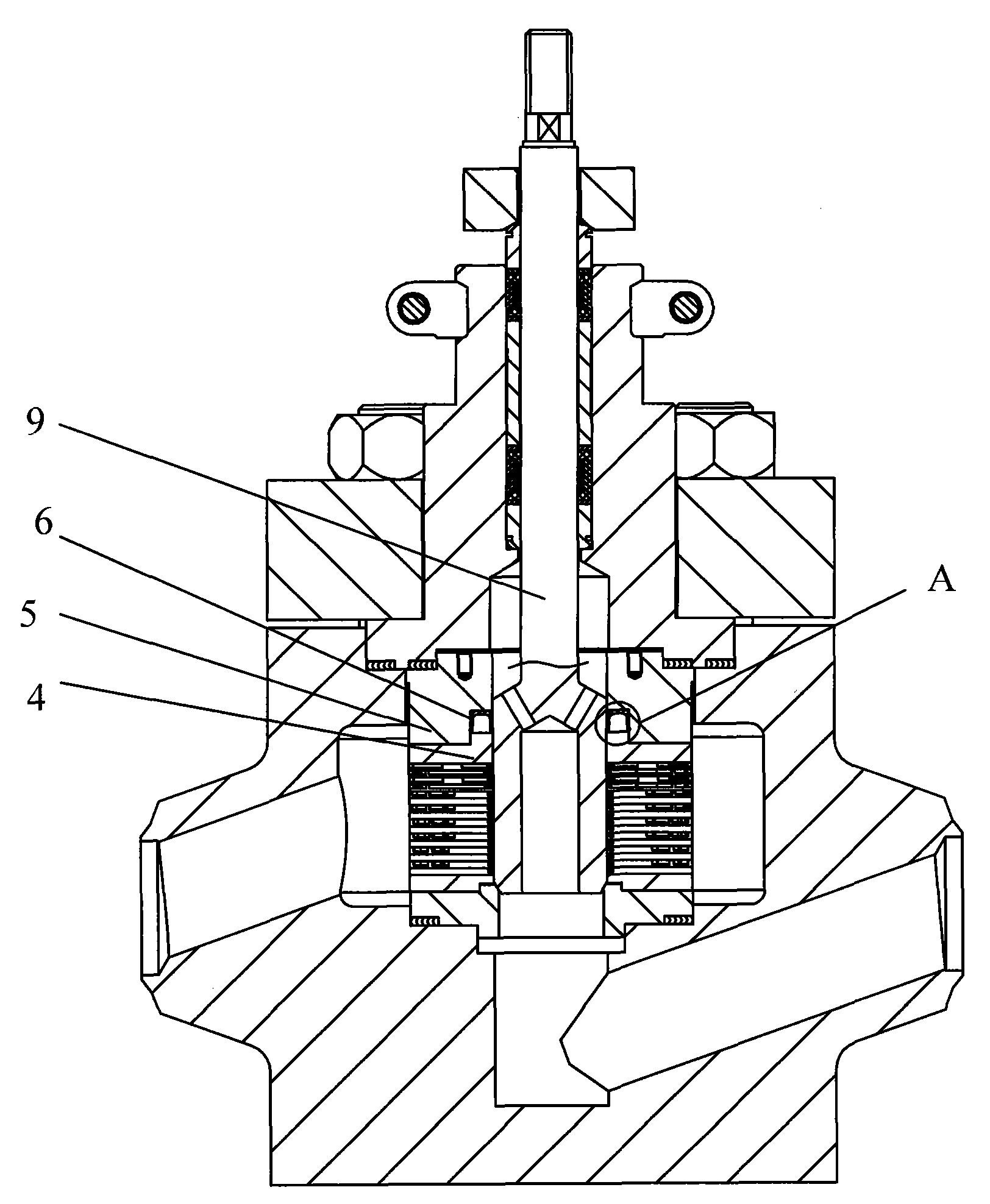

[0010] Such as figure 1 As shown, the self-sealing hard double valve seat of the balanced valve core of the present invention includes a valve cage 4, an adjustment sleeve 5, a sealing ring 6 and a valve core 9, and the sealing ring 6 is arranged between the positioning steps of the valve cage 4 and the adjustment sleeve 5 , the sealing ring 6 adopts a U-shaped structure, and the sealing ring 6 is an elastic sealing ring. The inner diameter part of the sealing ring 6 contacts and seals with the valve core 9 , and the outer diameter part of the sealing ring 6 contacts and seals with the positioning step of the adjusting sleeve 5 .

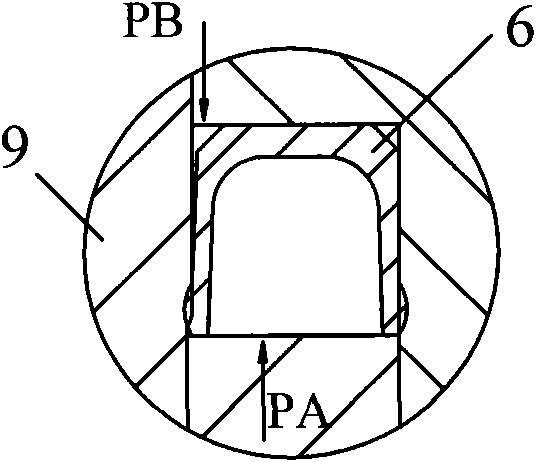

[0011] Such as figure 2 As shown, during use, the medium inlet pressure is PA, and the medium outlet pressure is PB. When the valve core is closed, the upper end pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com