Shield structure of transformer oil tank and mounting method thereof

A transformer oil tank and shielding structure technology, applied in the direction of transformer/inductor cooling, preventing/reducing unnecessary electric/magnetic influence, etc., can solve problems affecting product quality, difficult to clean, difficult to fuse, etc. slag, improve the quality of the fuel tank, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

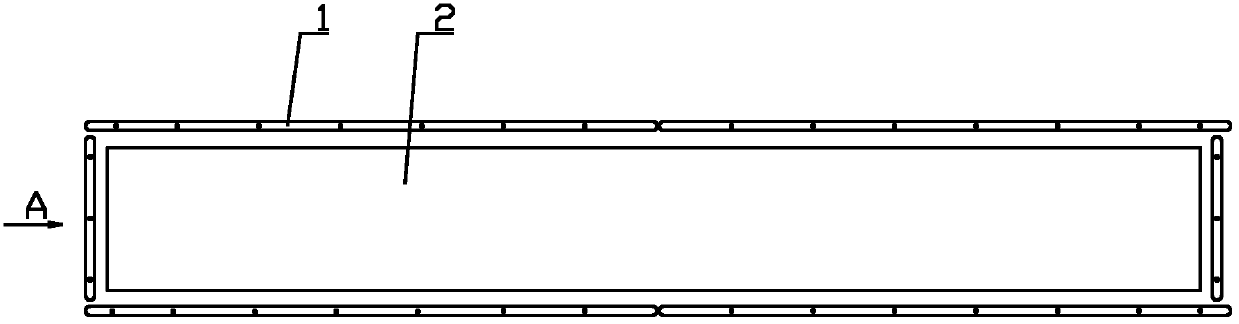

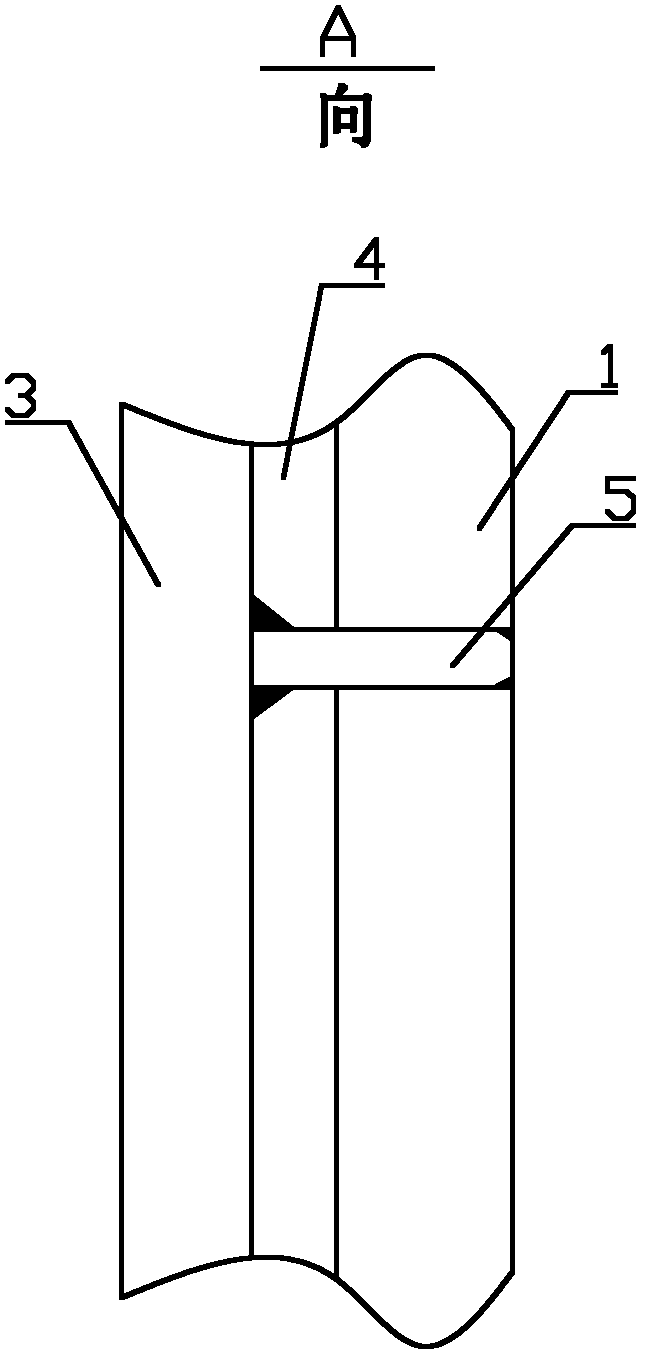

[0016] A transformer oil tank shielding structure, as shown in the figure, includes an oil tank, a copper shielding plate 4 is welded on the outside of the oil tank wall 3, a magnetic shielding plate 2 is installed on the outside of the copper shielding plate 4, and the copper shielding plate 4 around the magnetic shielding plate 2 There is a hole on it, and a pin 5 with a diameter of 12cm made of a low-magnetic material steel plate is inserted. One end of the pin 5 is welded to the wall 3 of the fuel tank, and the other end of the pin 5 is hung with a stainless steel protective tube 1 with a diameter of 45cm. The protective tube 1 has a hole with a diameter of 14cm at the corresponding position, and the other end of the pin 5 is welded with the stainless steel protective tube 1, and the protruding part of the pin 5 is ground flat. When making the pin, the length of the pin is determined according to the thickness of the copper shielding plate and the magnetic shielding plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com