Core-sheath conjugate fiber

A composite fiber, core-sheath technology, applied in the direction of conjugated synthetic polymer rayon filament, etc., to achieve the effect of reducing fabric damage, excellent stretchability, and easy wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

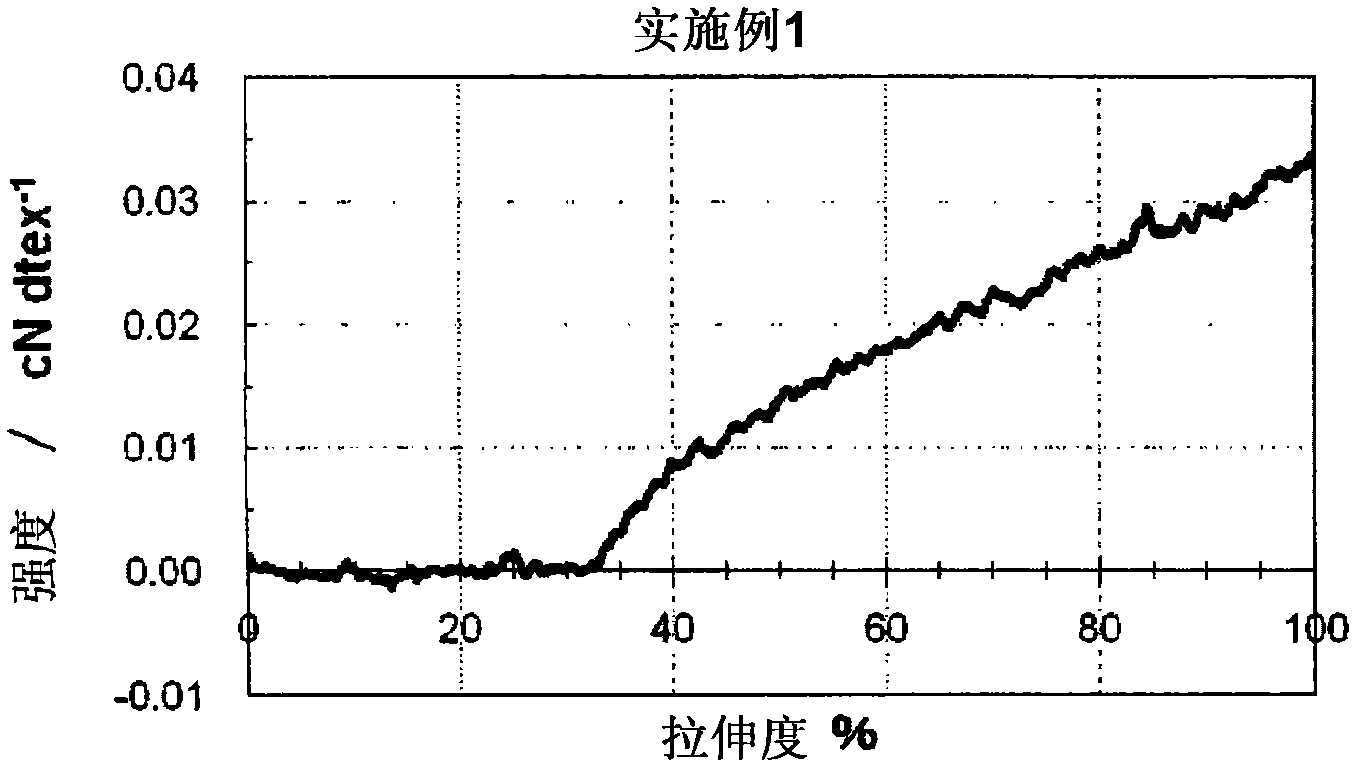

Embodiment 1-1

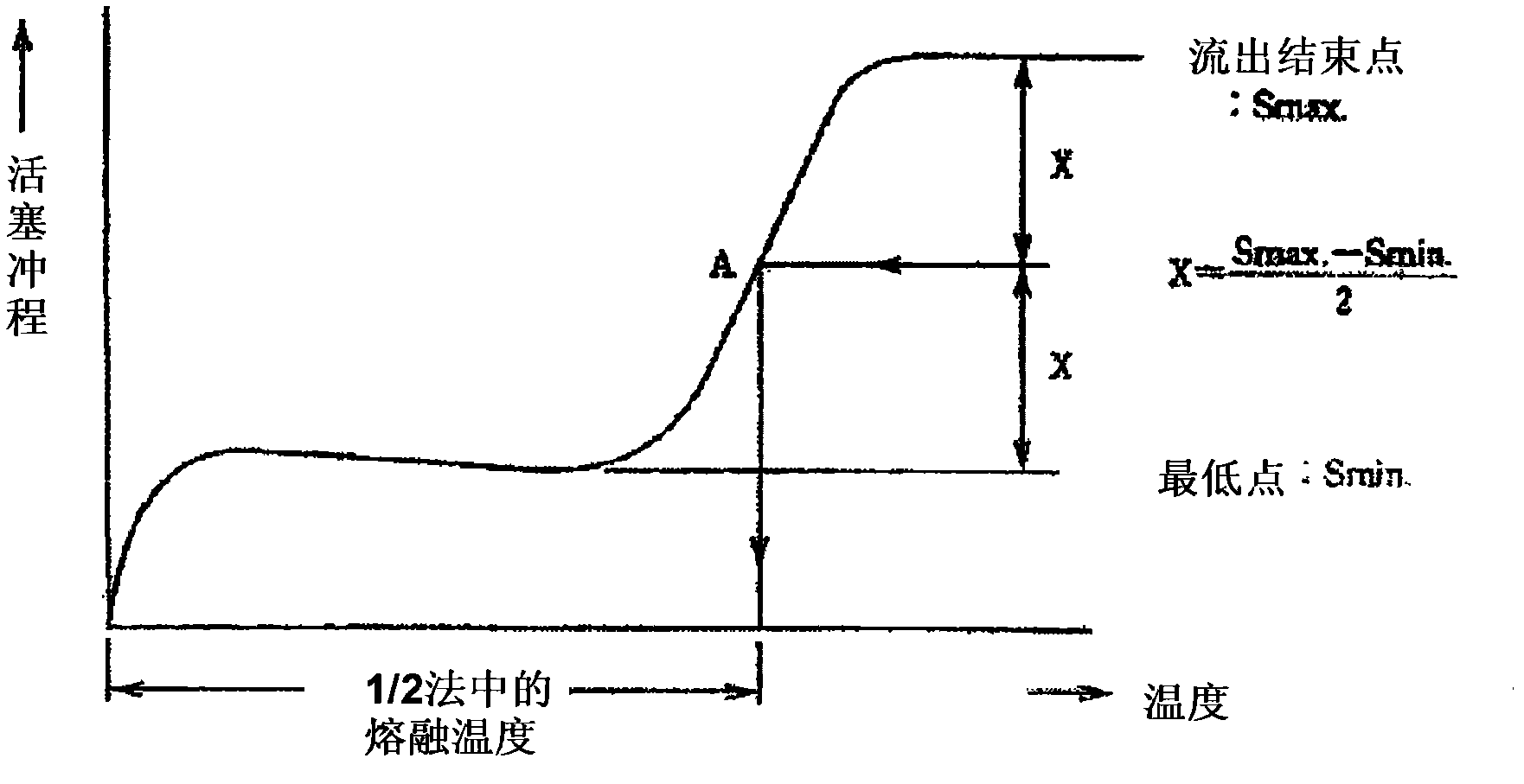

[0149] Heat and melt thermoplastic polyurethane (Pandex T-1185N produced by DIC Bayer Polymer Co., Ltd., 1 / 2 method melting temperature 214°C) and polyester through a single-screw extruder at a barrel temperature of 170-205°C and 180-220°C, respectively. Elastomer (Pelprene P-55B produced by Toyobo Co., Ltd., melting temperature of 1 / 2 method is 197 ° C), after metering with each gear pump, from the spinneret with 2 composite nozzles heated to 225 ° C, thermoplastic polyurethane The core part and the polyester elastomer as the sheath part are used for composite spinning in a concentric circle.

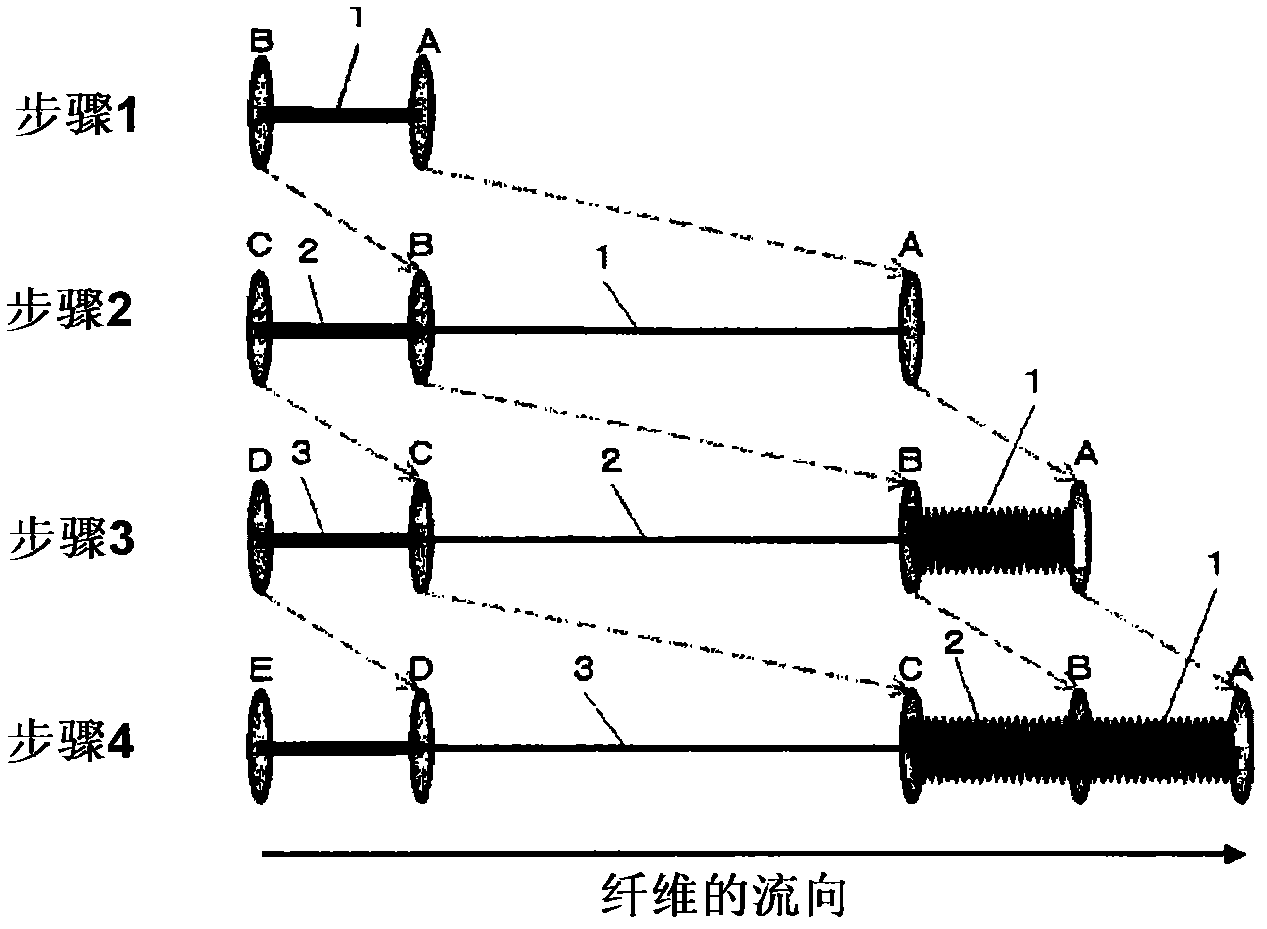

[0150] At a winding speed of 800m / min, the silicone oil is attached and wound in an unstretched state. After that, heat treatment (60°C, 55%RH in a humid heat environment) for 12 hours is carried out in a separate process, and the The filament fed by the roller at 100m / min passes through the room temperature roller which rotates at almost the same speed (104m / min), then passes through ...

Embodiment I-2~I-10

[0155] The core material, core ratio, sheath material, and sheath ratio were set as described in Table 1. In addition, pantyhose was produced in the same manner as in Example I-1. Sufficient crimping was given to the obtained fiber, and the pantyhose obtained using this fiber passed evaluations other than transparency.

Embodiment II-1

[0211] Heat and melt thermoplastic polyurethane (Pandex T-1190N produced by DIC Bayer Polymer Co., Ltd., surface hardness A92 (JIS K7311)) and polyester elastic through a single-screw extruder at a barrel temperature of 170-205°C and 180-220°C, respectively. Body (Pelprene P-90B produced by Toyobo Co., Ltd., surface hardness D52 (ASTM D2240)), measured by each gear pump, heated to 225°C through a composite nozzle, with thermoplastic polyurethane as the core part, polyester amide ester elastic The body becomes the sheath part and the composite spinning is concentric.

[0212] At a winding speed of 800m / min, the silicone oil was attached and wound in an unstretched state. After that, heat treatment was performed for 12 hours (under a humid heat environment of 60°C and 55%RH) in a separate process, and the The silk supplied by the room temperature roller at 100m / min is contacted and heated by a 90°C hot roller rotating at almost the same speed (104m / min), and a 155°C heating roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com