Control system for internal combustion engine

A technology for control systems and internal combustion engines, applied in engine control, fuel injection control, internal combustion piston engines, etc., can solve problems such as different intake air volume, reduced combustion stability, and increased exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

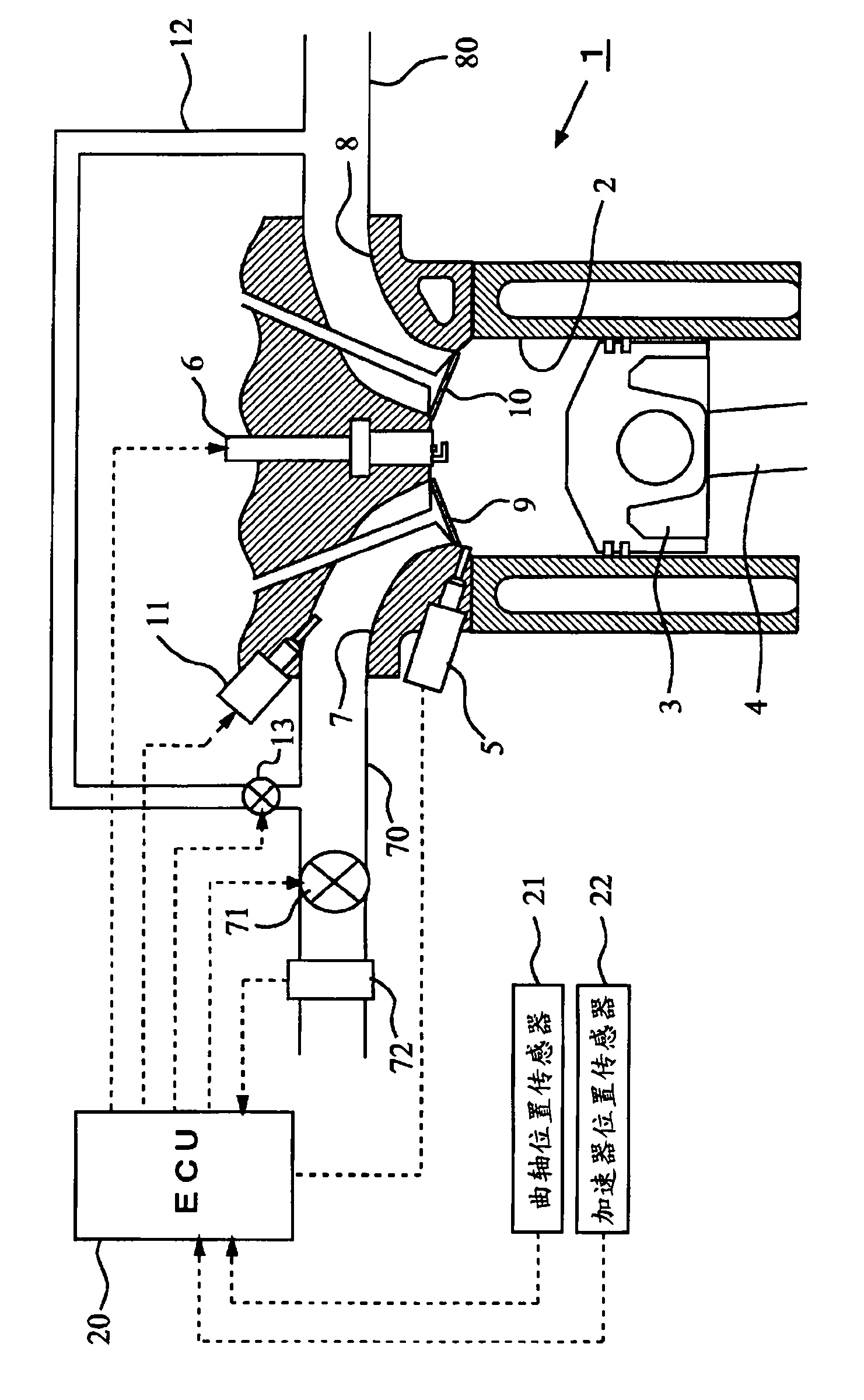

[0053] First, based on Figure 1 to Figure 10 A first embodiment of the present invention will be described. figure 1 is a diagram showing a schematic configuration of an internal combustion engine to which the present invention is applied.

[0054] figure 1 The shown internal combustion engine 1 is a 4-stroke cycle spark ignition internal combustion engine (gasoline engine) having a plurality of cylinders. Among them, in figure 1 In represents only 1 cylinder among the plurality of cylinders.

[0055] A piston 3 is slidably housed in each cylinder 2 of the internal combustion engine 1 . The piston 3 is connected to an unillustrated output shaft (crankshaft) via a connecting rod 4 . Furthermore, a first fuel injection valve 5 for injecting fuel into the cylinder and an ignition plug 6 for igniting the air-fuel mixture in the cylinder are attached to each cylinder 2 .

[0056] The inside of the cylinder 2 communicates with an intake port 7 and an exhaust port 8 . An open...

Embodiment 2

[0094] Next, based on Figure 11 A second embodiment of the present invention will be described. Here, configurations different from those of the aforementioned first embodiment will be described, and descriptions of the same configurations will be omitted.

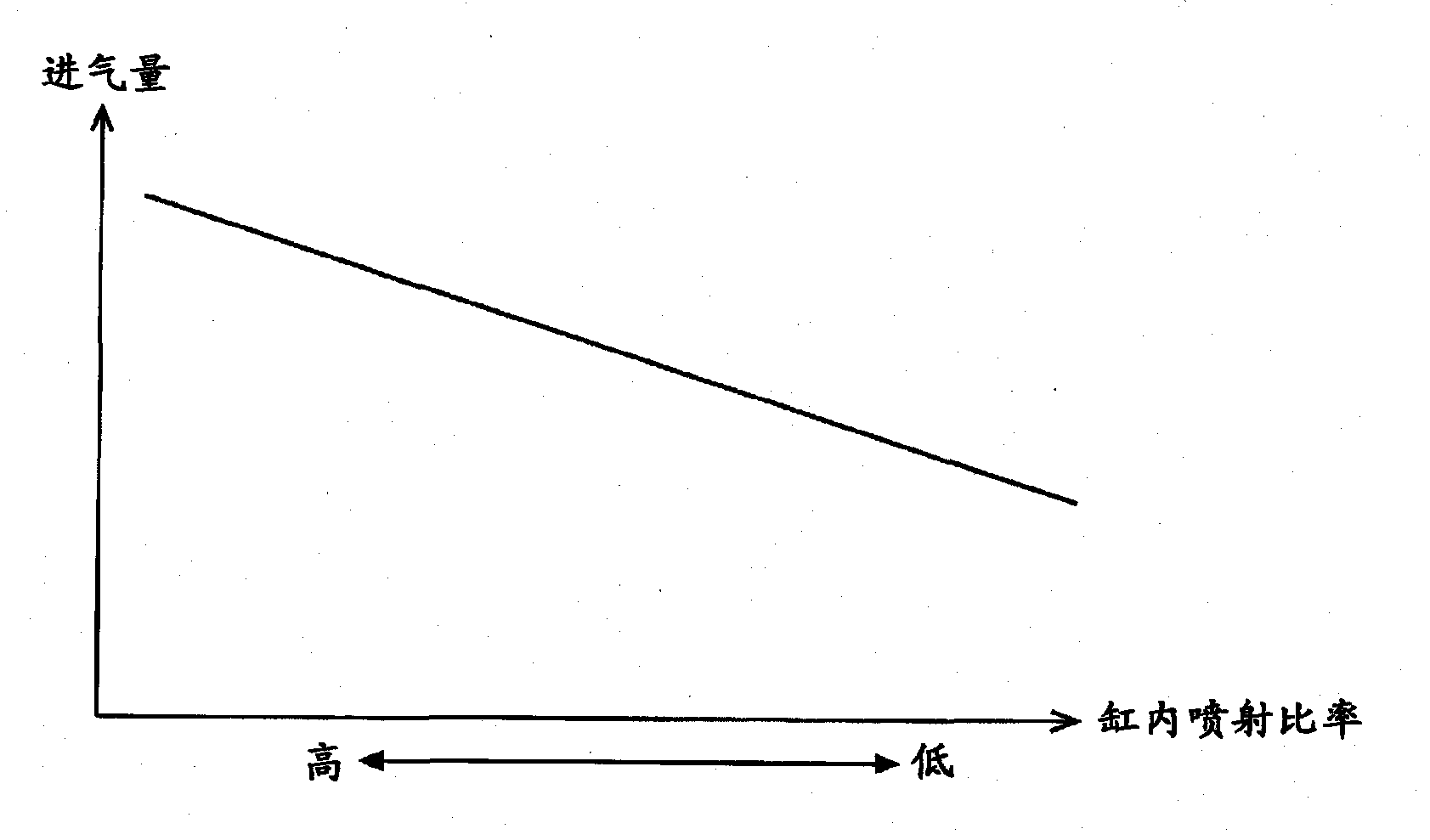

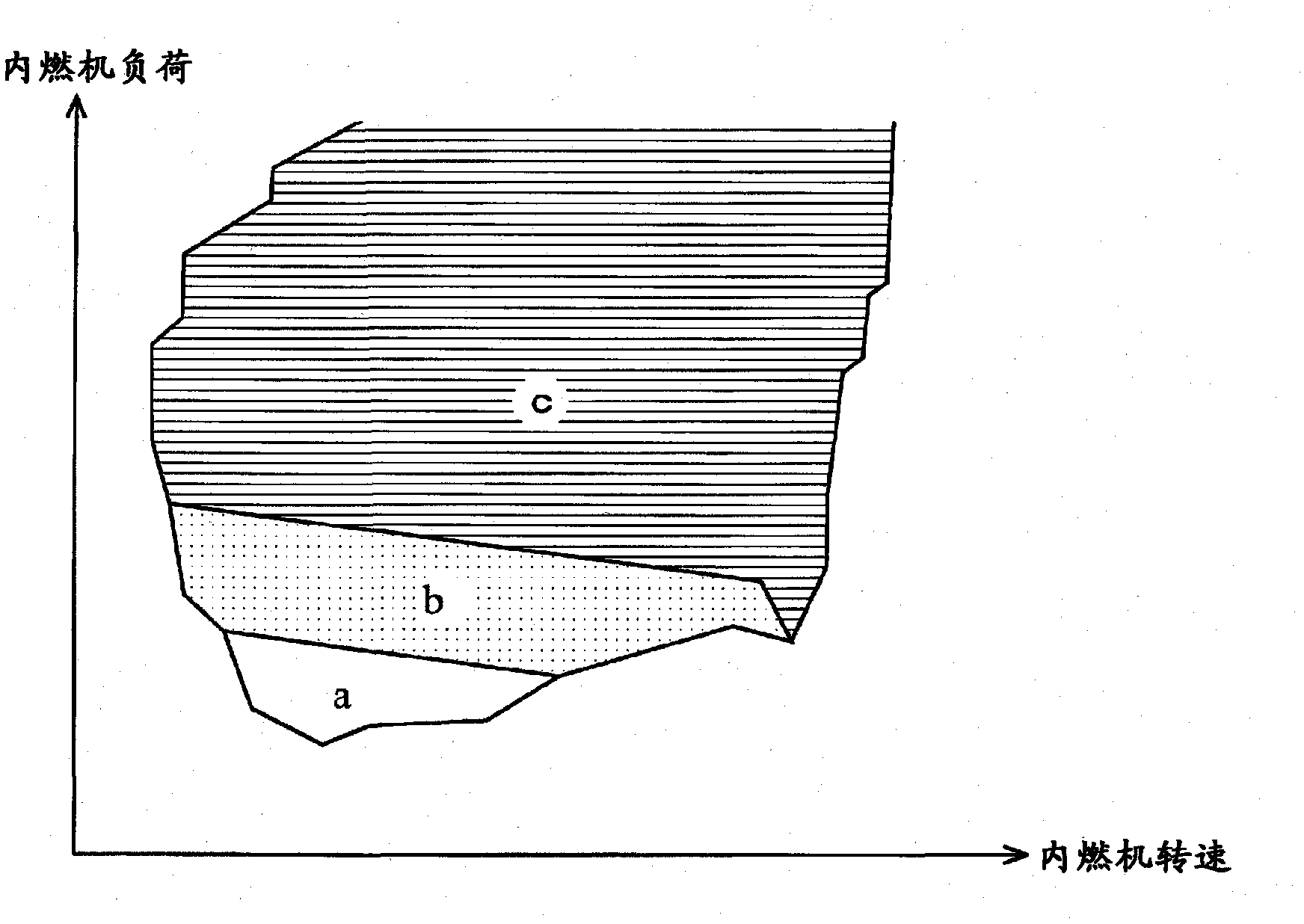

[0095] In the aforementioned first embodiment, an example was described in which the detection value of the air flow meter 72 is corrected when the in-cylinder injection ratio changes transitionally. However, in this embodiment, when the in-cylinder injection ratio and This is an example of correcting the detection value of the air flow meter 72 at the transient time when the opening degree of the EGR valve 13 is changed.

[0096] For example, when the operating state of the internal combustion engine 1 shifts from the EGR non-operating region to the EGR operating region, the actual opening degree of the EGR valve 13 does not immediately converge to the target EGR valve opening degree. In addition, since the EGR gas tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com