Printing window curtain

A printing and curtain technology, applied to curtains, drapes, window decorations, etc., can solve the problems of limited patterns and colors, high cost, and achieve the effect of increasing the anti-ultraviolet effect, reasonable structure design and wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

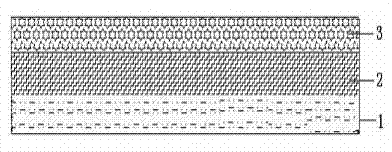

[0017] Such as figure 1 Shown, a kind of printed curtain, it comprises cotton spinning cloth layer (1), the anti-ultraviolet plastic cloth (2) that is stitched on one side of cotton spinning cloth layer (1), and its bonding on the other side of cotton spinning cloth layer (1) printed film on the side (3).

[0018] The above-mentioned printing film (3) is a plane printing made of PVC, PPO, PET materials by hot pressing.

[0019] In the printed curtain mentioned above, the anti-ultraviolet plastic cloth (2) is made of plastic cloth and anti-ultraviolet powder coating coated on the plastic cloth.

Embodiment 2

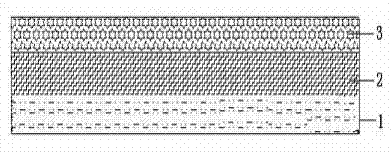

[0021] A printed curtain, which comprises a cotton fabric layer (1), an anti-ultraviolet plastic fabric (2) sewn on one side of the cotton fabric layer (1), and a printed fabric bonded on the other side of the cotton fabric layer (1) film (3).

[0022] The above-mentioned printing film (3) is a three-dimensional printing made of PPO material by hot pressing.

[0023] In the printed curtain mentioned above, the anti-ultraviolet plastic cloth (2) is made of plastic cloth and anti-ultraviolet powder coating coated on the plastic cloth.

Embodiment 3

[0025] A printed curtain, which comprises a cotton fabric layer (1), an anti-ultraviolet plastic fabric (2) sewn on one side of the cotton fabric layer (1), and a printed fabric bonded on the other side of the cotton fabric layer (1) film (3).

[0026] The above-mentioned printing film (3) is a three-dimensional printing made of PET material by hot pressing.

[0027] In the printed curtain mentioned above, the anti-ultraviolet plastic cloth (2) is made of plastic cloth and anti-ultraviolet powder coating coated on the plastic cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com