Microwave repair equipment for organic contaminated soil

An organic pollution and microwave technology, which is applied in the restoration of polluted soil, separation methods, and dispersed particle separation, etc., can solve the problems of incomplete treatment of organic tail gas, secondary pollution by combustion method, and remediation of organically polluted soil, so as to eliminate tail gas. The effect of secondary pollution problem, reducing energy consumption and improving start-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

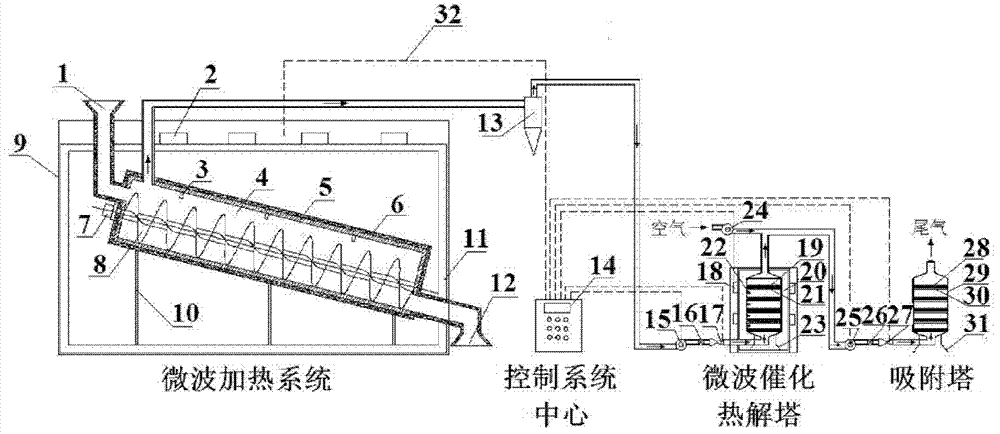

Image

Examples

example 1

[0031]For microwave remediation of easily hydrolyzed organic-contaminated soil, the organic-contaminated soil represented by chlorpyrifos is selected as the remediation object, and the concentration of chlorpyrifos in the organic-contaminated soil is 420mg / kg. The pretreated organic polluted soil passes through the mesh screen, and then enters the microwave remediation equipment of the organic polluted soil through the feeding port. The power of the first microwave generator was adjusted to 30kW, the average microwave irradiation time that the soil received dynamically in the furnace body was 30min, the soil temperature was maintained at about 200°C, and the removal rate of chlorpyrifos in the soil at the discharge port reached 96%. The gas flow rate before the microwave catalytic pyrolysis tower is 10m 3 / h, the power of the second microwave generator is adjusted to 10kw, the catalyst is Hopcalite catalyst, the temperature in the tower is maintained at about 350°C, and the ga...

example 2

[0033] For the microwave remediation of volatile / semi-volatile organic contaminated soil, the organic contaminated soil represented by nitrophenol was selected for the remediation test, and the concentration of nitrophenol in the organic contaminated soil was 480mg / kg. The pretreated organic polluted soil passes through the mesh screen, and then enters the microwave remediation equipment of the organic polluted soil through the feeding port. The power of the first microwave generator is adjusted to 45kW, the average microwave irradiation time that the soil dynamically accepts in the furnace body is 30min, the soil temperature is maintained at about 300°C, and the removal rate of nitrophenol in the soil at the discharge port reaches 98%. . The gas flow rate before the microwave catalytic pyrolysis tower is 10m 3 / h, the power of the second microwave generator is adjusted to 5kw, the catalyst is Hopcalite catalyst, the temperature in the tower is maintained at about 350°C, and ...

example 3

[0035] For the microwave remediation of refractory organic contaminated soil, chloramphenicol was selected as the representative organic contaminated soil for the remediation test, and the concentration of chloramphenicol in the organic contaminated soil was 120mg / kg. After the pretreated organic polluted soil is pretreated by the mesh screen, it enters the microwave remediation equipment of the organic polluted soil through the feeding port. The power of the first microwave generator is adjusted to 80kW, the average microwave irradiation time that the soil dynamically accepts in the furnace body is 30min, the soil temperature is maintained at about 500°C, and the degradation rate of chloramphenicol in the soil at the discharge port reaches 80%. . The gas flow rate before the microwave catalytic pyrolysis tower is 10m 3 / h, the second microwave generator is not turned on, the catalyst is Hopcalite catalyst, the temperature in the tower is maintained at about 600°C, and the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com