Composite cutter

A technology of composite cutting tools and cutting tools, which is used in drilling tool accessories, manufacturing tools, drilling/drilling equipment, etc. High pass rate, convenient replacement, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

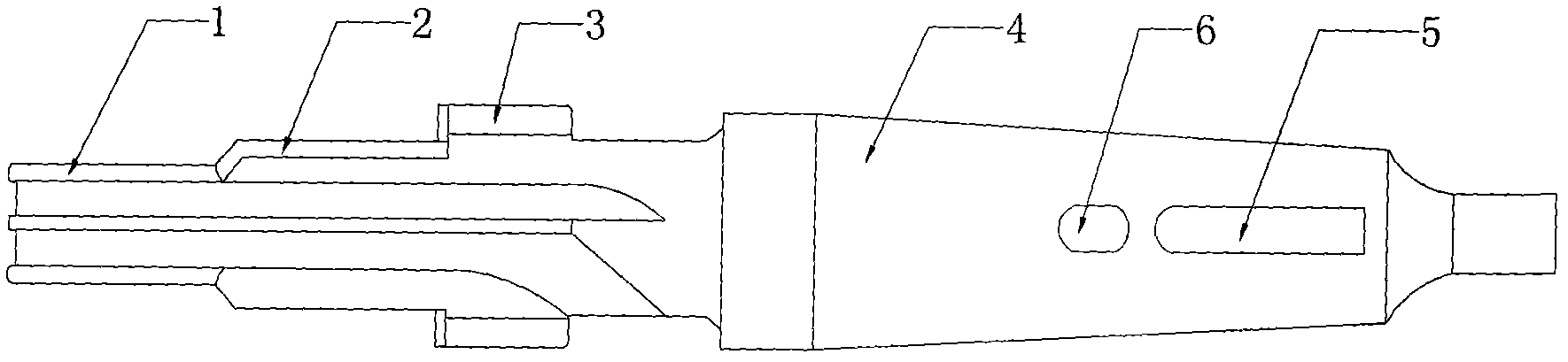

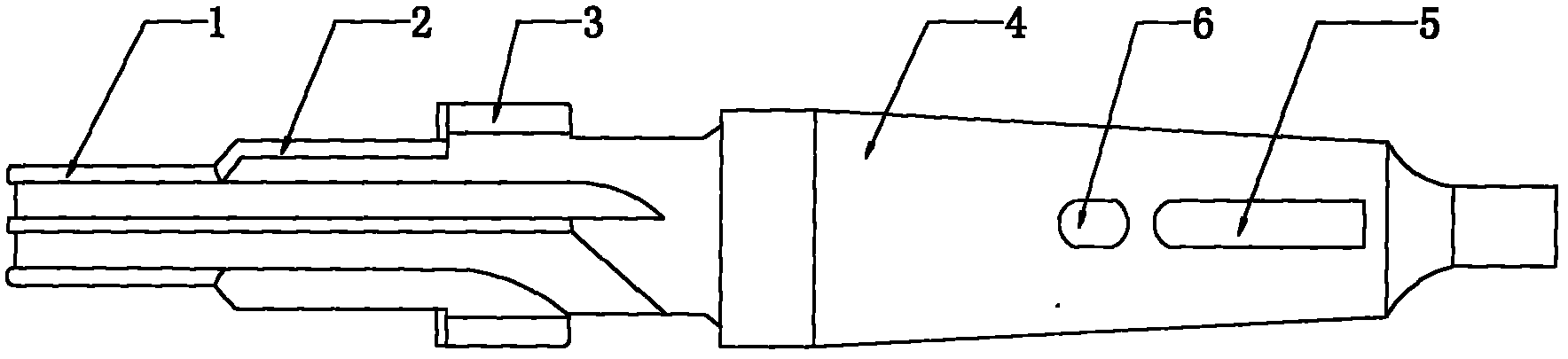

[0011] like figure 1 As shown, a compound tool is composed of a drill 1, a reamer 2, a countersink 3 and a handle 4, so that the tool can simultaneously perform drilling, reaming and hole end processing, and is formed at one time. For the production of cutting tools, the drilling tool 1, reamer 2 and countersinking tool 3 are designed as an integrated structure. In order to improve the stability and convenience of fixing the tool and the machine tool, a keyway 5 and a positioning groove 6 are set on the tool handle 4. Further, the handle 4 is designed into a tapered structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com