Ultrasonic processing tool for mold cavity

A processing tool and ultrasonic technology, applied in the field of mold cavity ultrasonic processing tools, to achieve the effects of convenient use, improved surface processing effect and efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

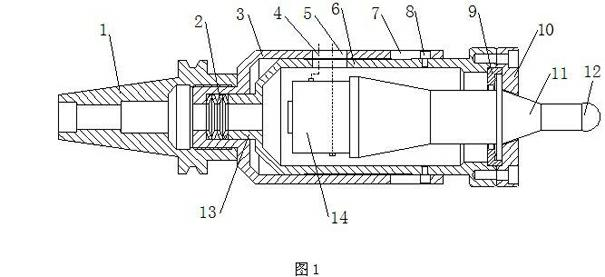

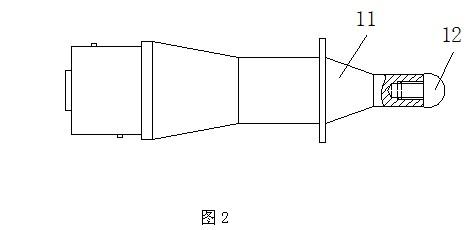

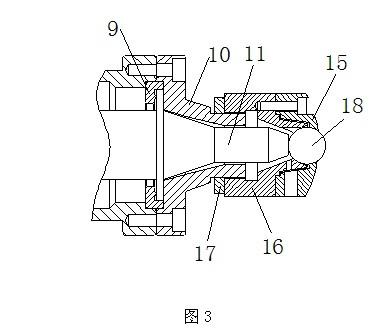

[0017] Such as figure 1 As shown, the mold cavity ultrasonic machining tool of the present invention includes a taper shank 1 , an outer shell 3 , an inner sleeve 6 , a transducer 14 and a horn 11 . The shell 3 and the taper shank 1 are connected together, and the connection method can be through a threaded connection, or through other forms such as a flange. The inner sleeve 6 is set in the outer shell 3, and the front end of the inner sleeve 6 protrudes from the outer shell 3, and a spring 2 is arranged between the inner sleeve 6 and the outer shell 3 in the axial direction, so that the inner sleeve 6 can be pressed against the outer shell 3 after being subjected to axial force. internal compression, figure 1 The middle is that the spring 2 is installed between the bottom of the inner sleeve 6 and the bottom of the shell 3 . There is also a limit device when the inner cover 6 moves between the inner sleeve 6 and the outer shell 3. The limit device is to install a limit pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com