Simple package heat shrinkage film printing method and heat shrinkage film prepared according to method

A printing method and heat-shrinkable film technology, applied in the field of printing, can solve the problems of affecting the appearance, increase the process and material cost, reduce the process and material, improve the printing quality, and overcome the effect of being easily scratched off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] The printing process uses a domestic multi-color film printing machine to print the pattern of "XX beer" on a layer of biaxially oriented polypropylene film (BOPP film), in which the word "XX beer" is red and light brown is used as the background color of the pattern; " XX brand beer" is darker in color with a lighter brown base color.

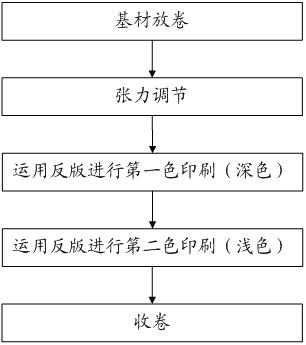

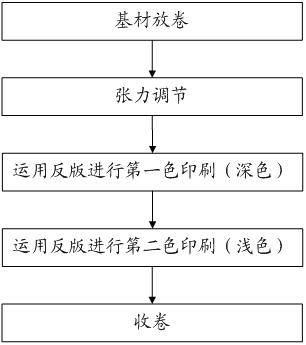

[0053] according to figure 1 As shown, the plate making is carried out according to the following process: substrate unwinding - printing machine tension adjustment - using reverse plate, printing dark "XX beer" - drying - printing is lighter than "XX beer" Brown background color - drying - deviation correction - slitting - winding.

[0054] Among them, the main process parameters are as follows:

[0055] Printing material: BOPP film

[0056] Number of printing groups: 8 groups

[0057] Printing speed: 120m / min

[0058] Effective printing width: 800mm

[0059] Unwinding diameter: 1500mm

[0060] Rewinding diameter: 1500mm

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com