Packing machine core

A movement, integrated technology, applied in the direction of strapping machinery parts and other directions, can solve the problems of easy corrosion and rust, low service life, high failure rate, improve service life and quality, simplify production process, and meet mass production. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

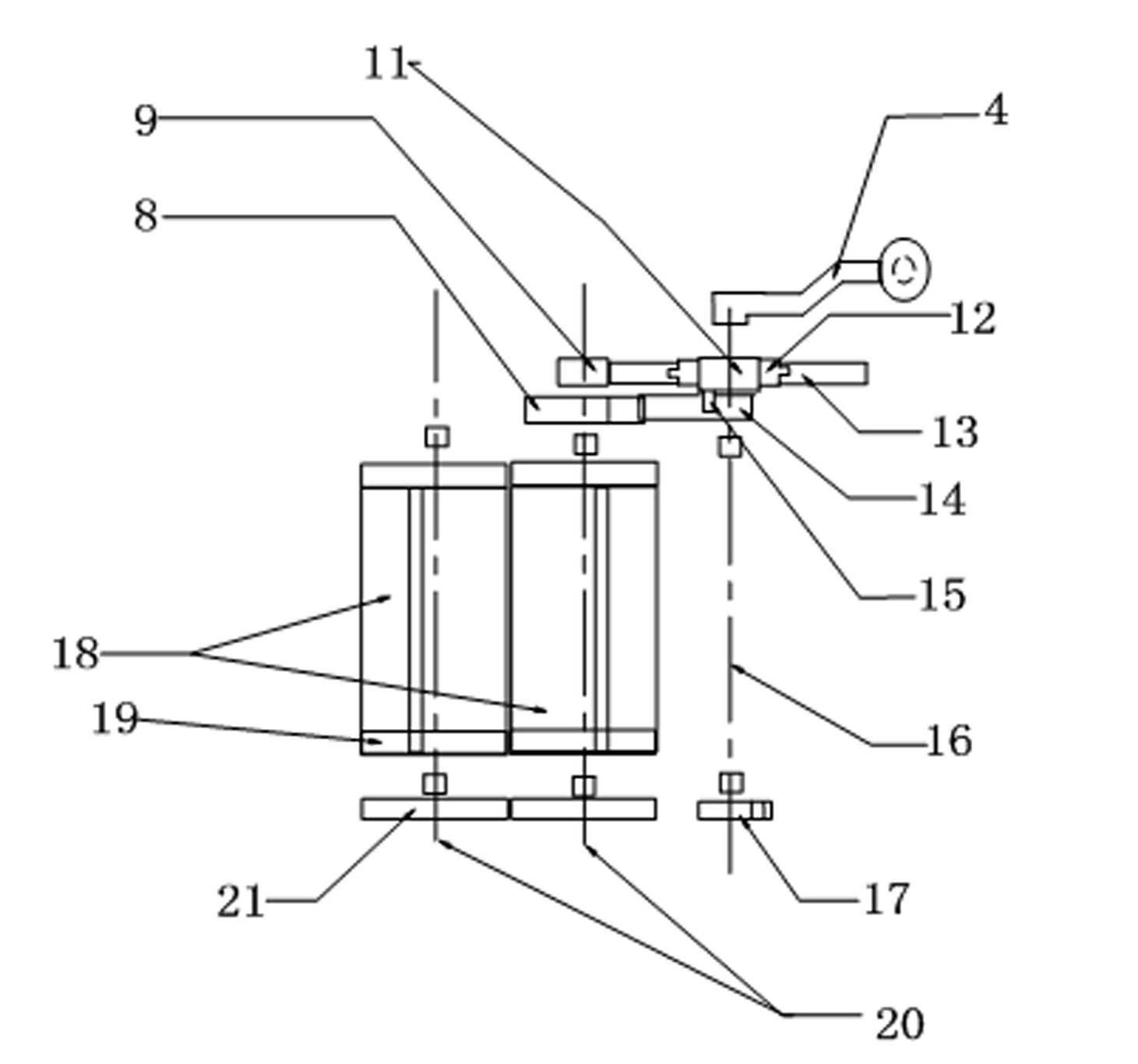

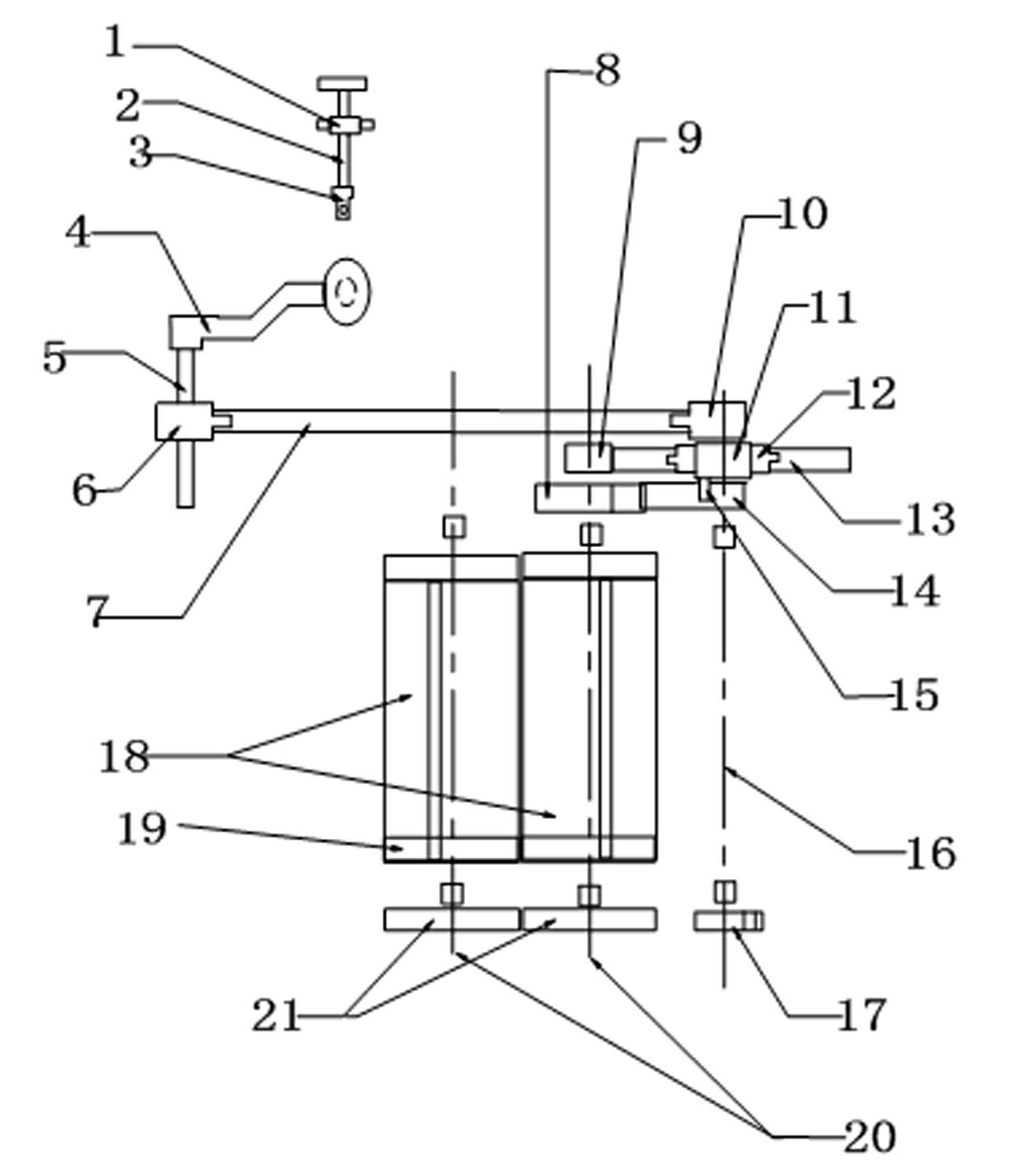

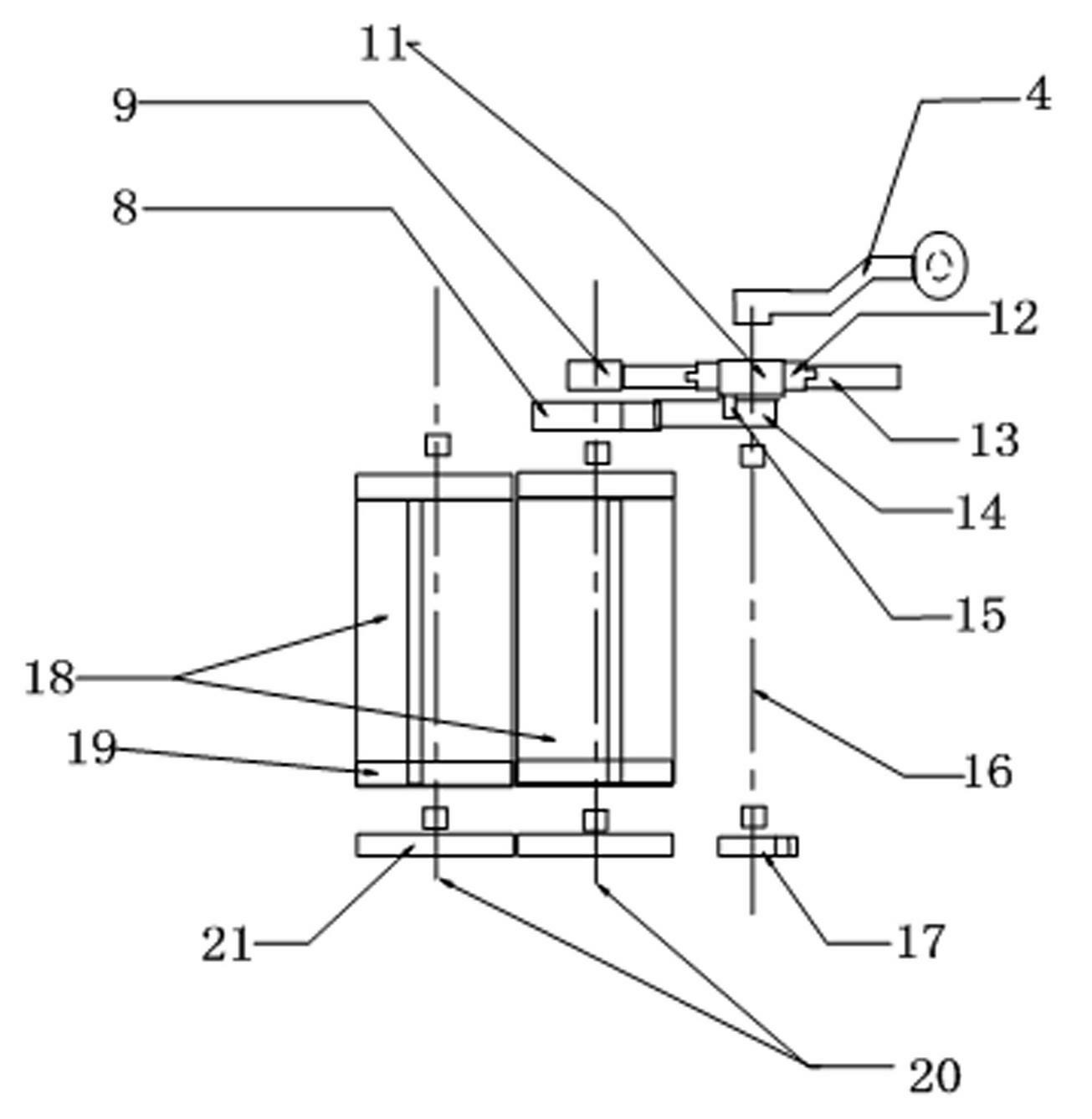

[0065] Such as figure 1 As shown, a packing movement includes a pulling link 4, a main shaft 16, a ratchet transmission mechanism, a limit mechanism, a shaft 20, a sealing mechanism, a linkage gear 21, and a return coil spring 17, wherein the pulling link 4 It is directly connected with one end of the main shaft 16, and the return coil spring 17 is connected with the other end of the main shaft 16, and the main shaft 16 runs through the ratchet transmission mechanism, the limit mechanism and the return in turn. Bit coil spring 17; the limiting mechanism is connected with the sealing mechanism through the shaft 20, and the sealing mechanism is connected with the linkage gear 21 through the shaft 20.

[0066] The rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com