Winding machine

A winding machine and winding technology, which is used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of irregular winding coils, low degree of automation, and unsightly appearance, and achieve regularity. Consistent with tightness, high degree of automation and fast winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

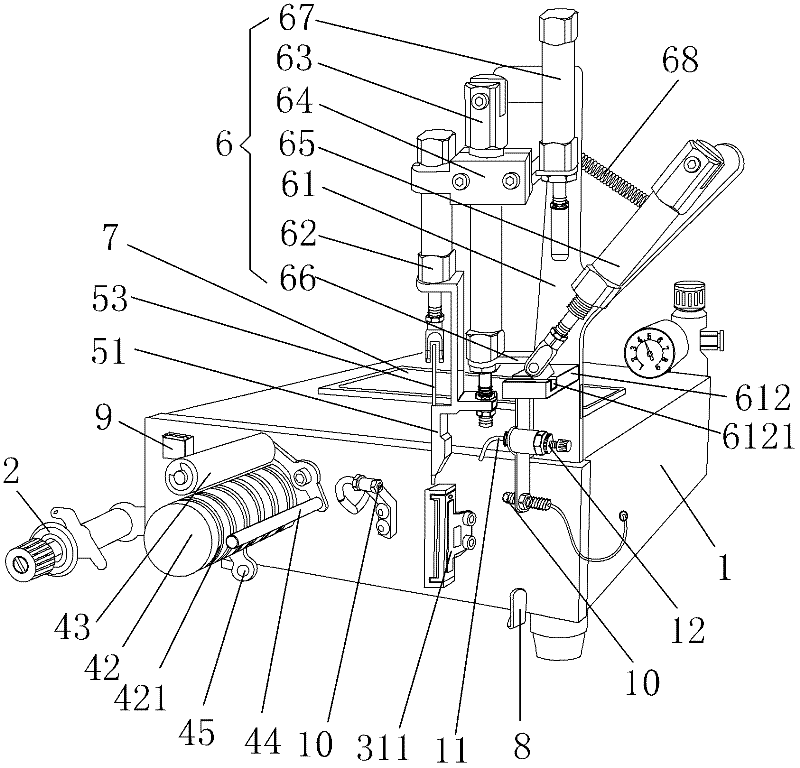

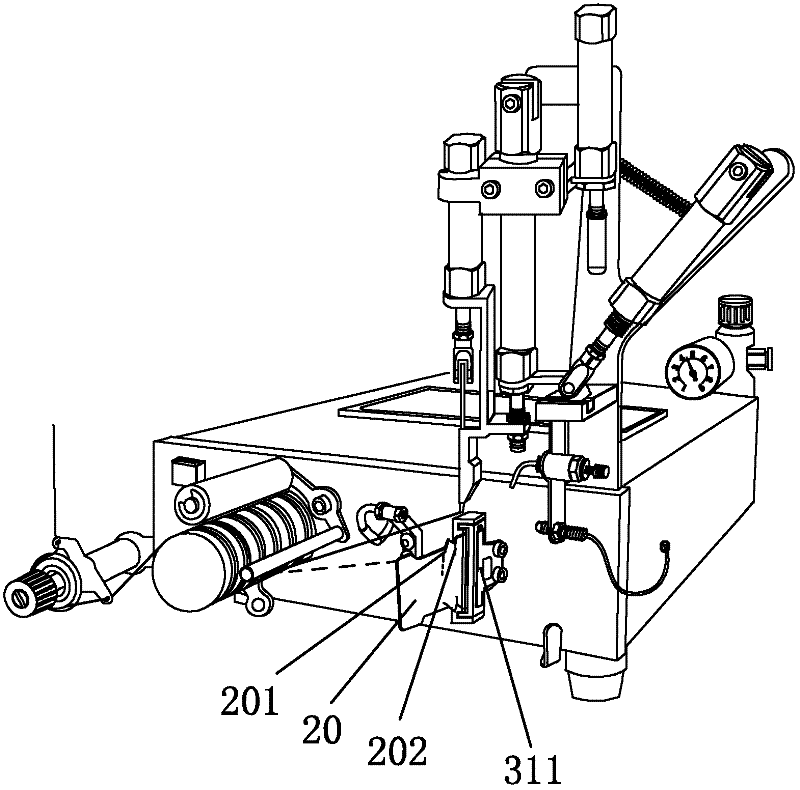

[0026] Figure 1 to Figure 10 Shown, a kind of winding machine comprises:

[0027] The seat body 1 for installing each mechanism, one side of the seat body 1 is equipped with a tension mechanism 2 for introducing yarn, the tension mechanism 2 includes an elastic thread cylinder 21 longitudinally arranged on the seat body, and the elastic thread cylinder 21 piston rod is threaded in turn Two clips 22, spring 23 and the nut 24 locked on the piston rod of the elastic line cylinder 21;

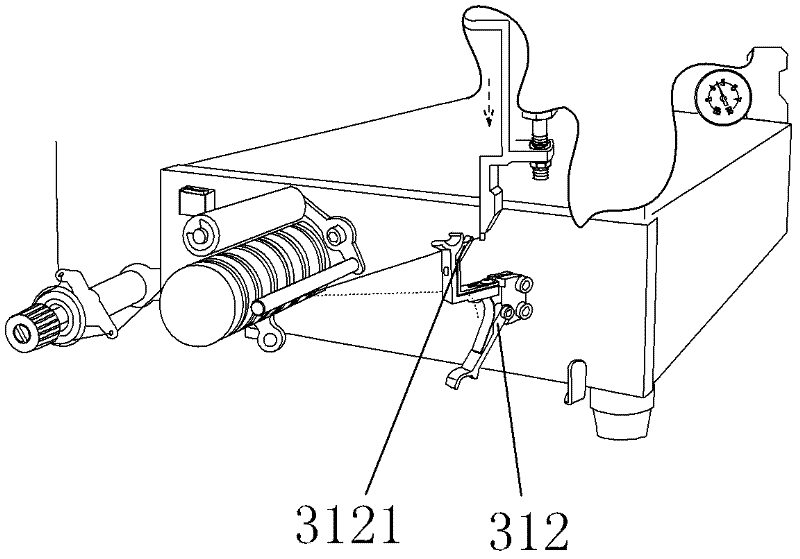

[0028] The winding stepper motor 3 installed on the base 1, the drive shaft 31 of the winding stepper motor 3 protrudes longitudinally in front of the base 1, and the core winding clamp can be installed on the winding stepper motor 3 drive shaft 31 311 or coreless winding fixture 312;

[0029] The cable stepper motor 4 installed on the base bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com