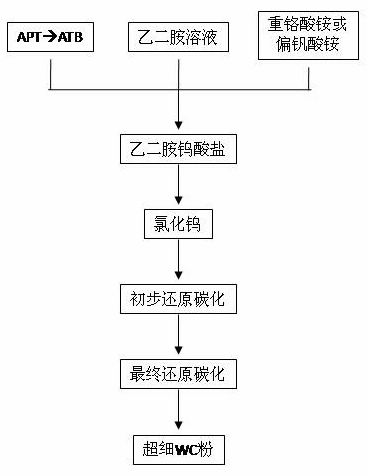

Technology for preparing ultrafine WC powder containing grain growth inhibitors Cr and V

A technology for grain growth and inhibition of grain growth, applied in the technical field of preparation of ultra-fine WC powder containing grain growth inhibitors Cr and V Problems such as storage and transportation difficulties, WC particles grow up, etc., to achieve the effects of easy control, sufficient supply, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In response to the urgent demand for ultra-fine WC powder at home and abroad, through years of repeated tests, we have developed the preparation technology of ultra-fine WC powder containing grain growth inhibitors Cr and V, and have been used in several domestic cemented carbide products and Manufacturers of powder metallurgy products have been successfully applied. First, the superfine WC powder containing grain growth inhibitors Cr and V is evenly mixed with a certain proportion of Co powder, and then pressed into a certain shape of the blank to obtain a cemented carbide product with ultrafine grains after high-temperature vacuum sintering.

[0039]

[0040] Example 1: A cemented carbide manufacturer A in Zhuzhou City, Hunan Province, uses our ultra-fine WC powder containing grain growth inhibitors Cr and V to produce ultra-fine-grained cemented carbide molds, and its service life is ordinary 1.5 times that of cemented carbide molds.

[0041]

[0042] Example 2: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com