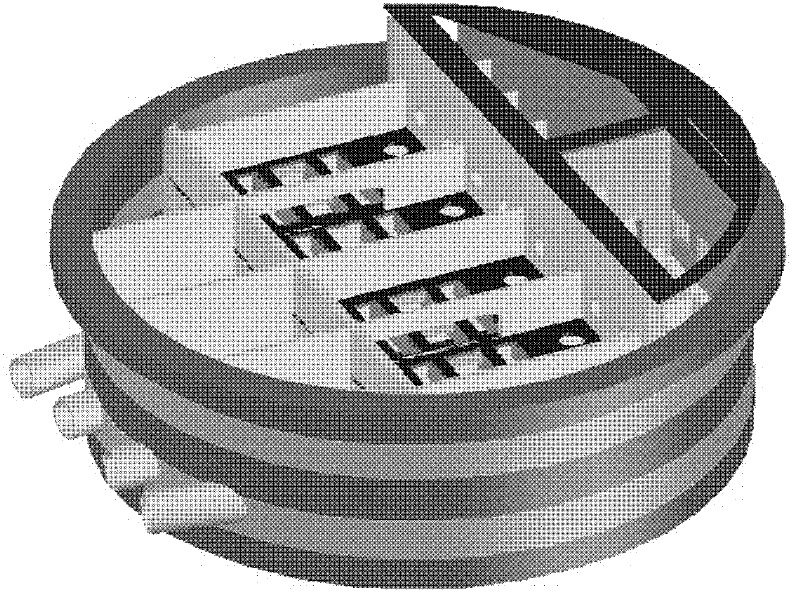

Water inlet pump chamber and method

A technology for water inlet pump room and pump room, which is applied in the field of water inlet pump room and sewage pretreatment system water inlet pump room, which can solve the problems of uneven sewage flow rate, backflow, and affecting the pretreatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

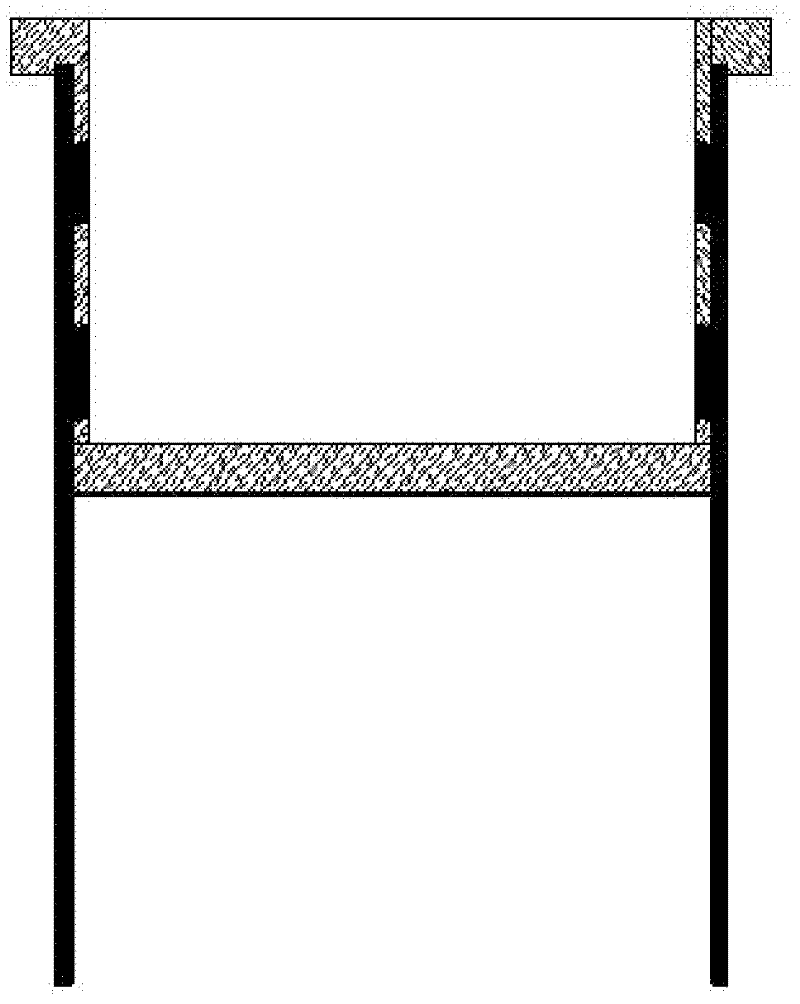

[0058] The present invention is described further in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

[0059] Inlet pump room construction plan:

[0060] 1. Preparation basis

[0061] "Code for Engineering Survey" (GB 50026-2007)

[0062] "Code for Building Deformation Measurement" (JGJ 8-2007)

[0063] "Code for Construction and Acceptance of Water Supply and Drainage Structures" (GBJ 141-90)

[0064] "Code for Building Structure Loads" (GB 50007-2002)

[0065] Code for Design of Concrete Structures (GB 50010-2002)

[0066] "Code for Design of Building Foundations" (GB 50007-2002)

[0067] "Code for design of reinforced concrete caisson structure for water supply and drainage engineering" (CECS 137: 2002)

[0068] 2. Project overview

[0069] 2.1. Process function of water inlet pump room:

[0070] The water inlet pump room is a sewage treatment structure that raises the sewage flowing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com