Piston combustion engine with variable bent axle radius

A technology for an internal combustion engine and a crankshaft is applied in the field of piston internal combustion engines with variable crankshaft radius, and can solve the problems of low effective thermal efficiency of the internal combustion engine and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

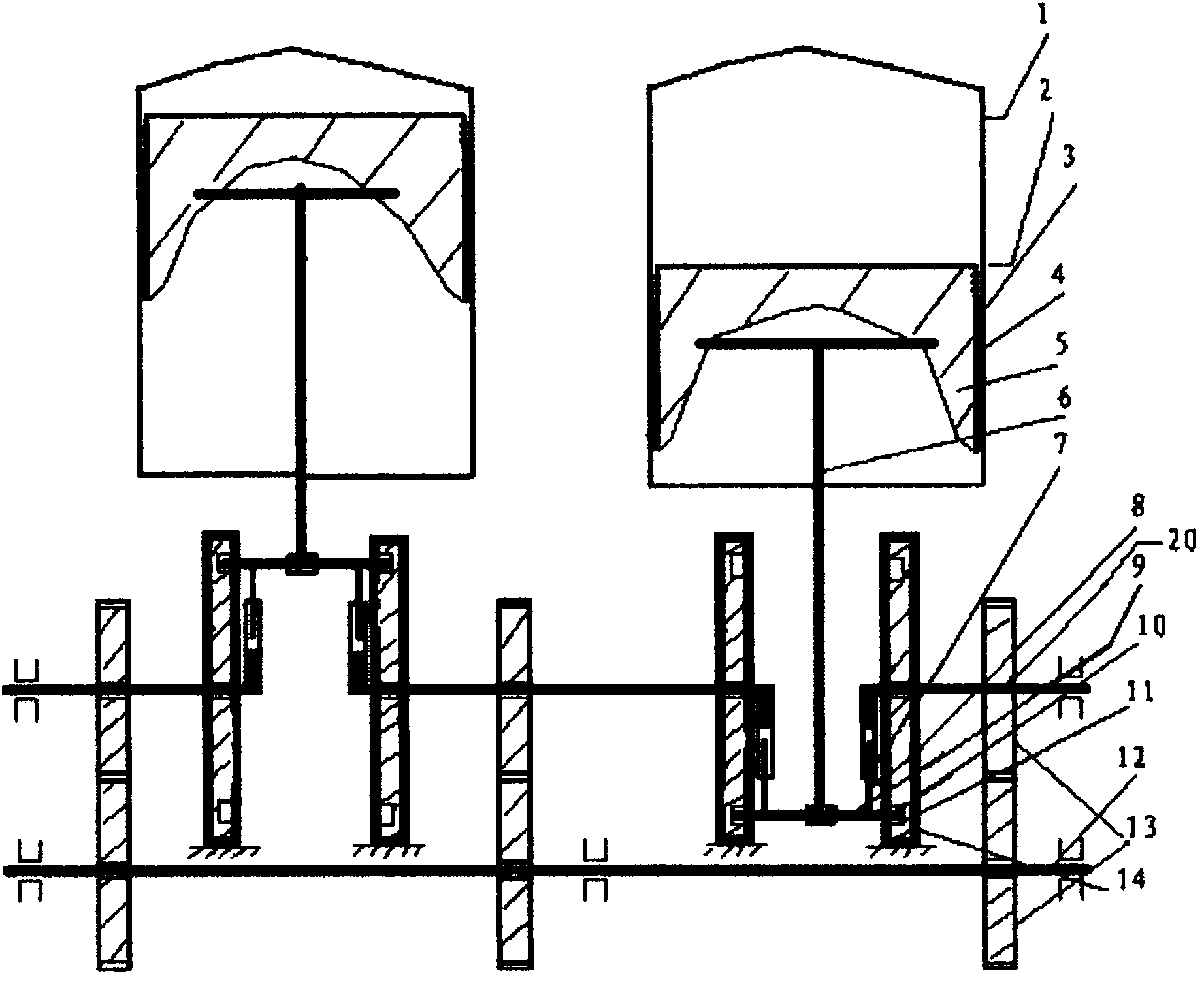

[0065] A crankshaft radius variable piston internal combustion engine, which includes a cylinder block 3, a piston 5, a connecting rod 6, and a crankshaft; the crankshaft used is installed and used in conjunction with the piston 5, and the piston 5 is arranged in the cylinder block 3 and along the Its inner wall slides; it is important to emphasize that:

[0066] The crankshaft used by the variable crankshaft radius piston internal combustion engine meets the following requirements: the crankshaft includes a crankshaft horizontal rod A20, a crankshaft horizontal rod B9, and a restraining groove plate 14 at the end of the crankshaft horizontal rod; wherein:

[0067] The crankshaft horizontal rod A20 basically coincides with the rotation axis of the crankshaft external support, and the crankshaft horizontal rod B9 is parallel to the rotation axis of the crankshaft external support;

[0068] The crankshaft horizontal rod end constraining groove plates 14 are arranged in pairs, an...

Embodiment 2

[0089] The content of this embodiment is basically the same as that of Embodiment 1, and the differences that need to be emphasized are:

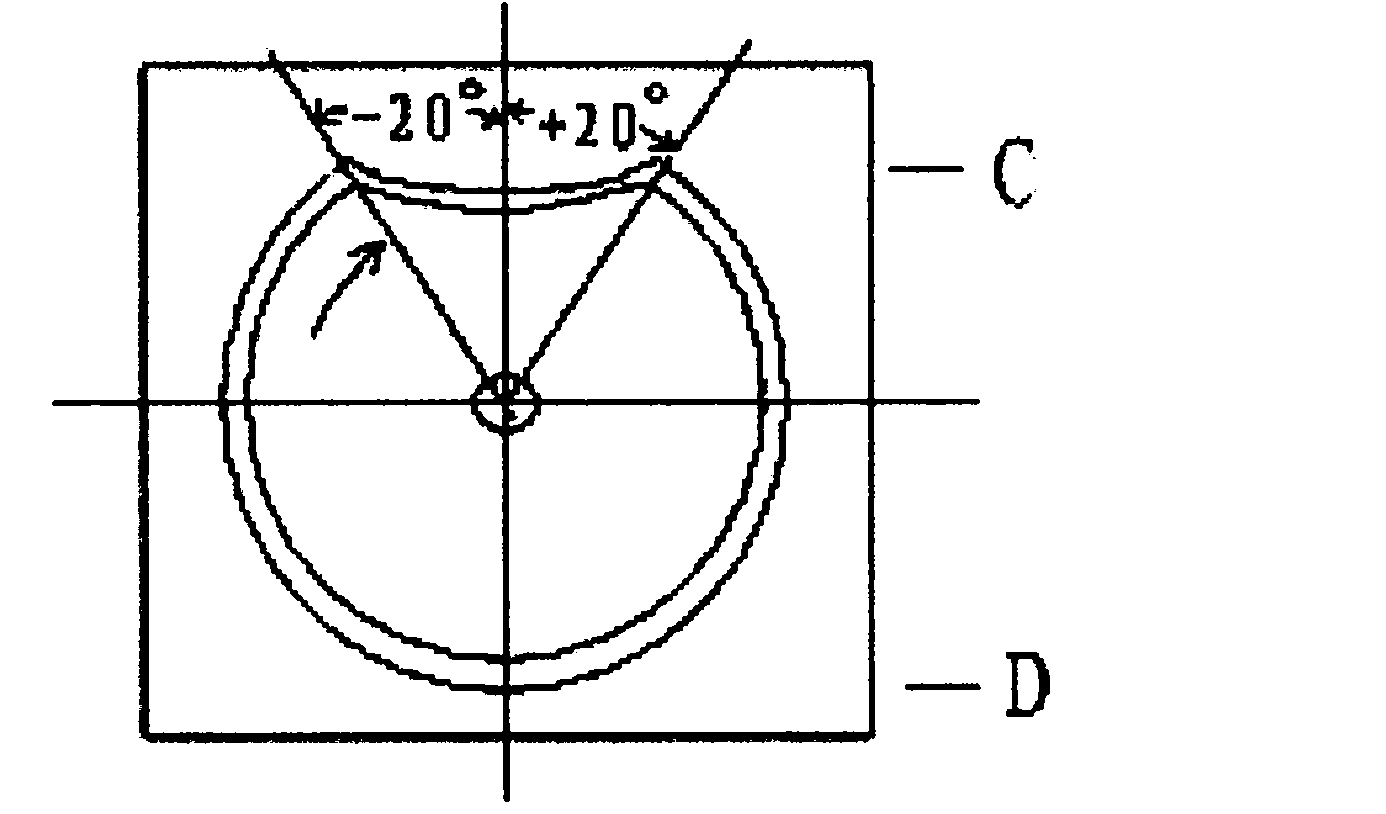

[0090] 1) Most of the paths of the restraining grooves 11 at the end of the crankshaft horizontal rod in the crankshaft of the crankshaft radius variable piston internal combustion engine are arranged along a circle with the same radius;

[0091] The remaining small part of the path is two parts separated by discontinuity in the whole path, and the distance between it and the crankshaft external support rotation axis is 60-140% of the radius of the aforementioned equal-radius circle track; The sum of the corresponding central angle ranges occupied by the circle path part in the circumferential direction is 80°, as shown in the attached image 3 .

[0092] 2) The specific shape of the non-equal-radius circle part of the constraint groove 11 at the end of the crankshaft horizontal rod is a combination of the following two types:

[0093] On...

Embodiment 3

[0100] The content of this embodiment is basically the same as that of Embodiment 1, and the differences that need to be emphasized are:

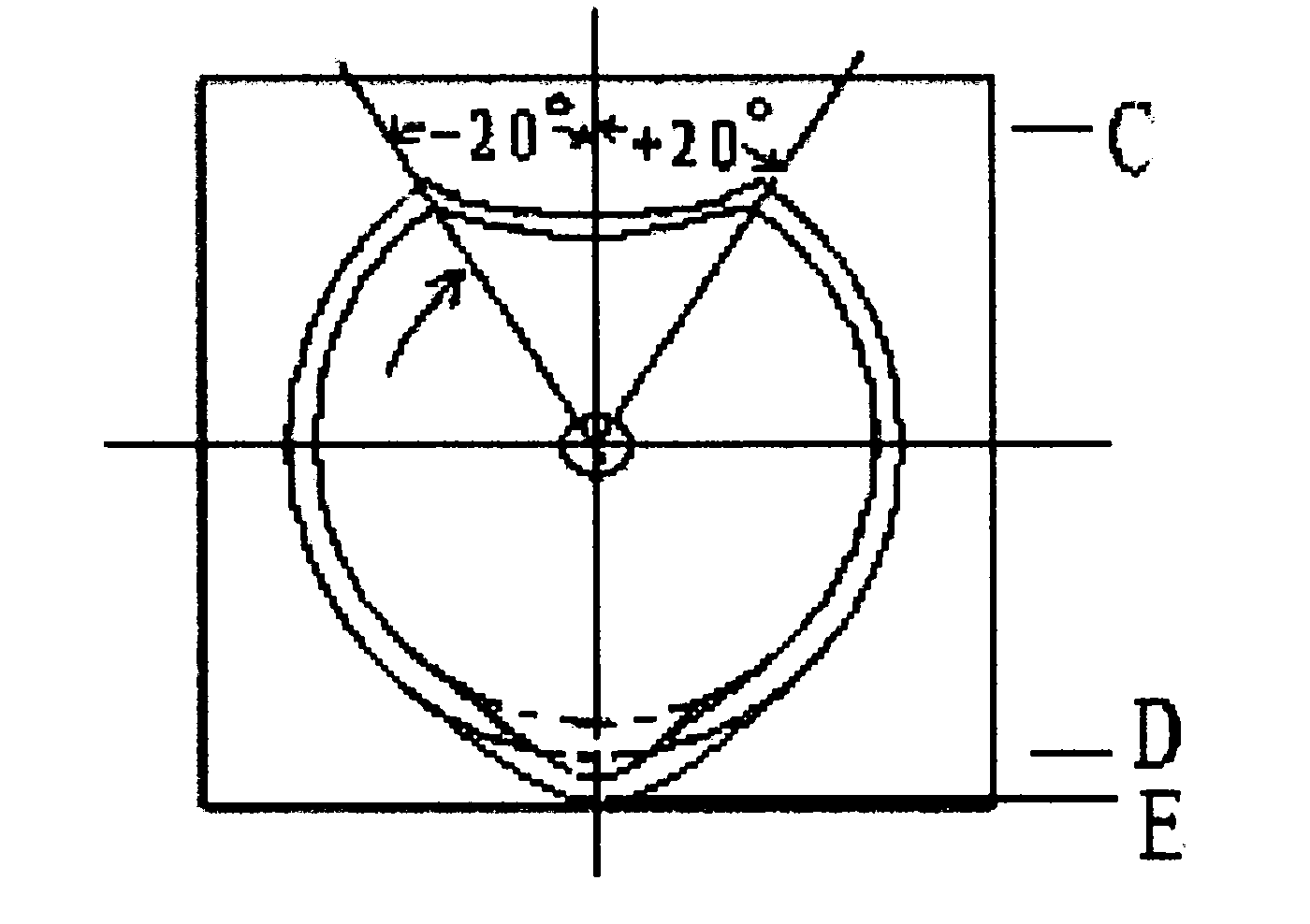

[0101] In the crankshaft of the crankshaft radius-variable piston internal combustion engine, most of the paths of the restraining grooves 11 at the end of the crankshaft horizontal rod are arranged along a circle with the same radius;

[0102] The remaining small part of the path is a continuous part in the whole path, and the distance between the center of the non-equal-radius path and the equal-radius path is 95% to 135% of the radius of the equal-radius circle track; The radius part is connected smoothly; the corresponding central angle range occupied by this part in the circumferential direction is 85°;

[0103] The non-equal radius path is a drop-shaped protrusion protruding away from the rotation center; as attached Figure 4 : The restraining groove 11 at the end of the crankshaft horizontal bar with an angle of 0° to 85° in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com