A graphite contact electrode for hollow cathode

A technology of hollow cathode and contact holding pole, which is applied in aerospace electric propulsion technology and the field of vacuum electronics, to achieve the effects of improving life and reliability, increasing sputtering corrosion resistance, and reducing the difficulty of processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

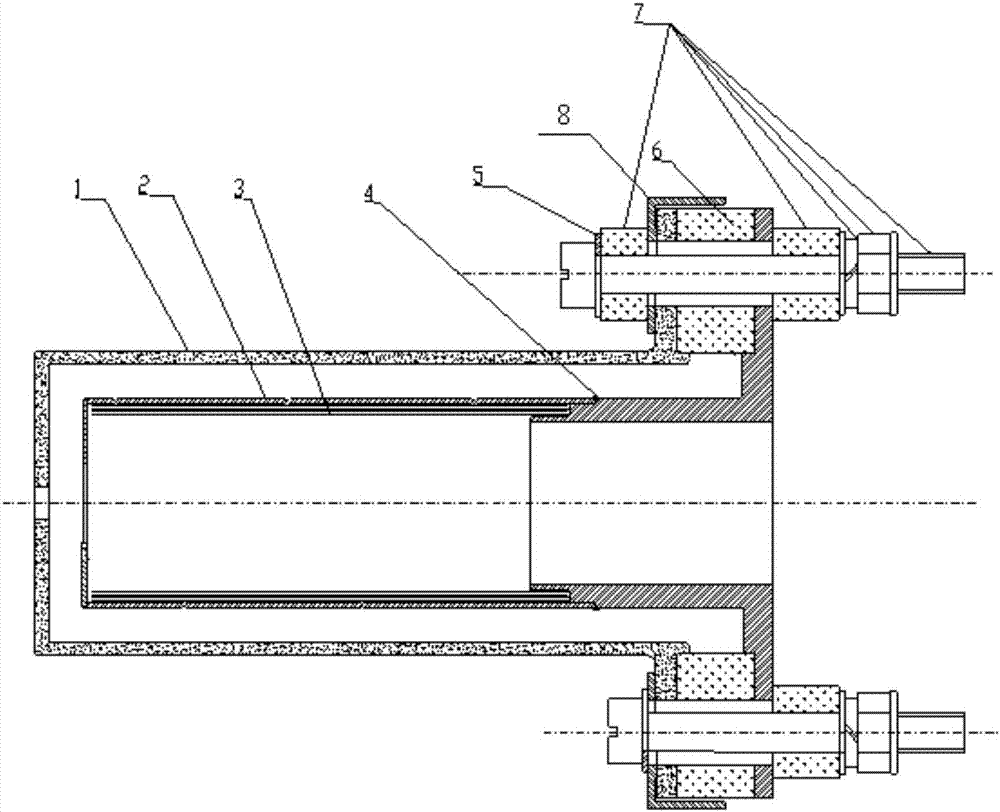

[0019] Such as figure 1 As shown, a graphite contact electrode for hollow cathode is mainly composed of contact electrode cylinder 1, heat shield jacket 2, molybdenum-rhenium foil 3, heat shield support 4, exhaust pad 5, insulating ceramic 6, fastening components 7 and a shielding cover 8;

[0020] The end surface of the closed end of the contact holding pole cylinder 1 is provided with a central hole, and the outer circumferential surface of the open end is provided with a radial installation plane; the material of the contact holding pole cylinder 1 has a density of 2.09g / cm 3 Graphite material with a purity >99.998%; the heat shield jacket 2 is a cylindrical structure with one end closed and one end open, rolled from tantalum foil, with a central hole on the end surface of the closed end, and rolled on the heat shield jacket The inner peri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com