A high-efficiency energy-saving environmental protection preheating type internal flame burner

A high-efficiency, energy-saving, burner technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problems of gas tempering, low combustion thermal efficiency, and insufficient combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

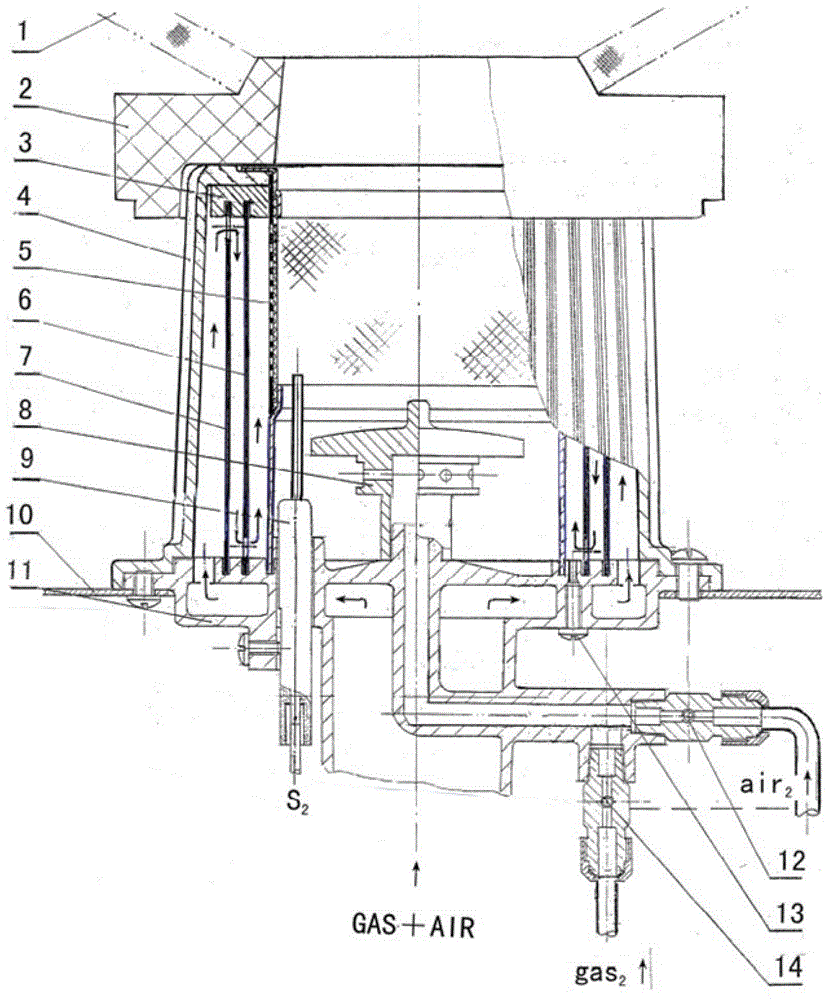

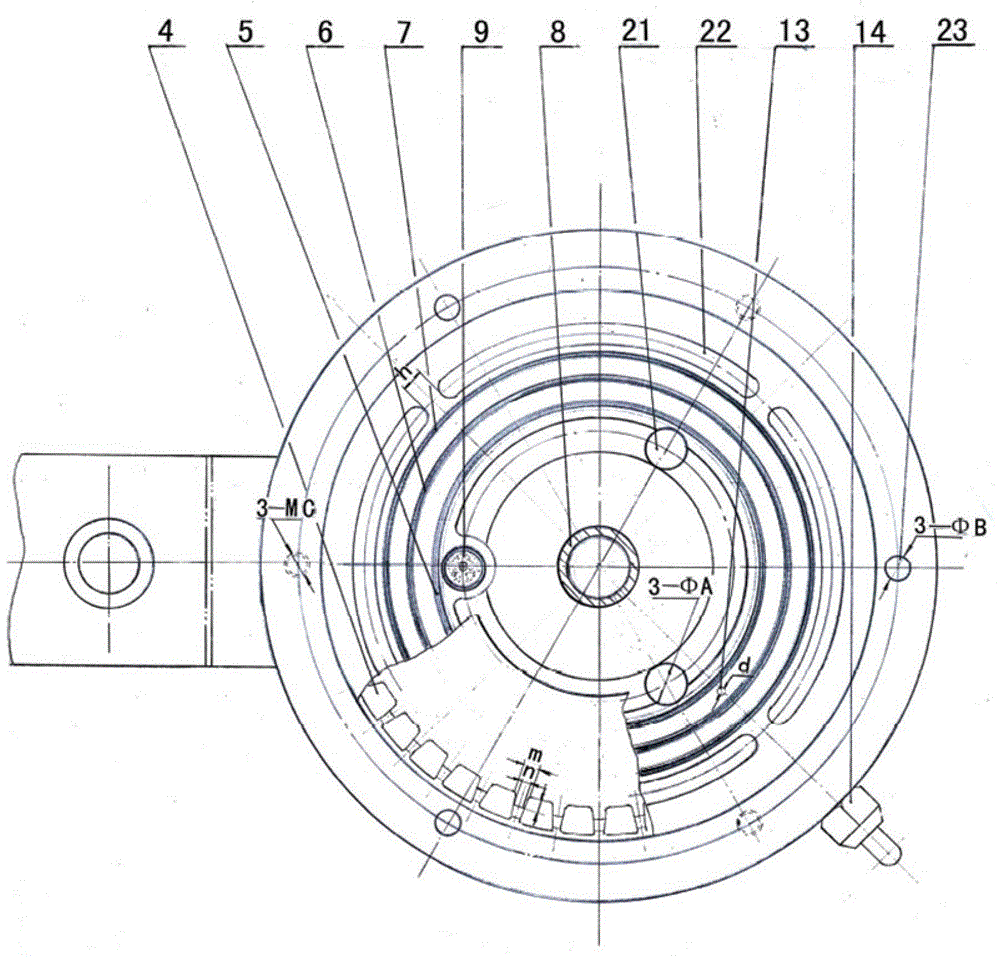

[0037] The present invention is illustrated below by way of non-limiting examples in conjunction with the accompanying drawings.

[0038] attached figure 1 In the middle is a more advanced operation embodiment of the present invention, that is, a schematic structural diagram of a high-efficiency, energy-saving, environment-friendly preheating type internal flame burner.

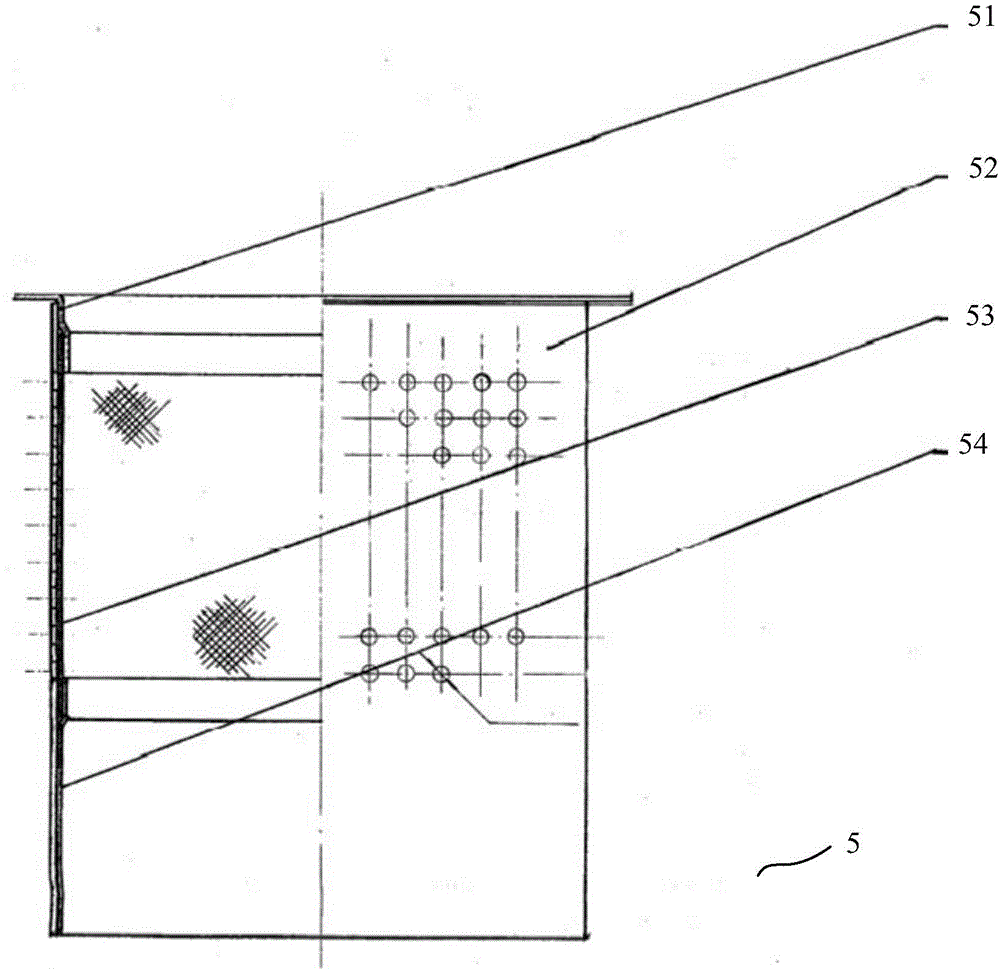

[0039] The structure of the preheating type internal flame burner of the present invention is mainly divided into two parts, the inside and the outside; wherein the outside is regulated by the fire air control valve 12 and the fire of the burner casting shell 4, the burner casting base 11 and the bottom outer end. Valve 14 etc. are made up. The inner upper end is covered by a compartment ring top cover 3 (see attached Figure 9 Interlayer ring top cover sectional view) slots are assembled, and the lower end is correspondingly engaged with the circumferential slots on the top of the burner casting base 11 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com