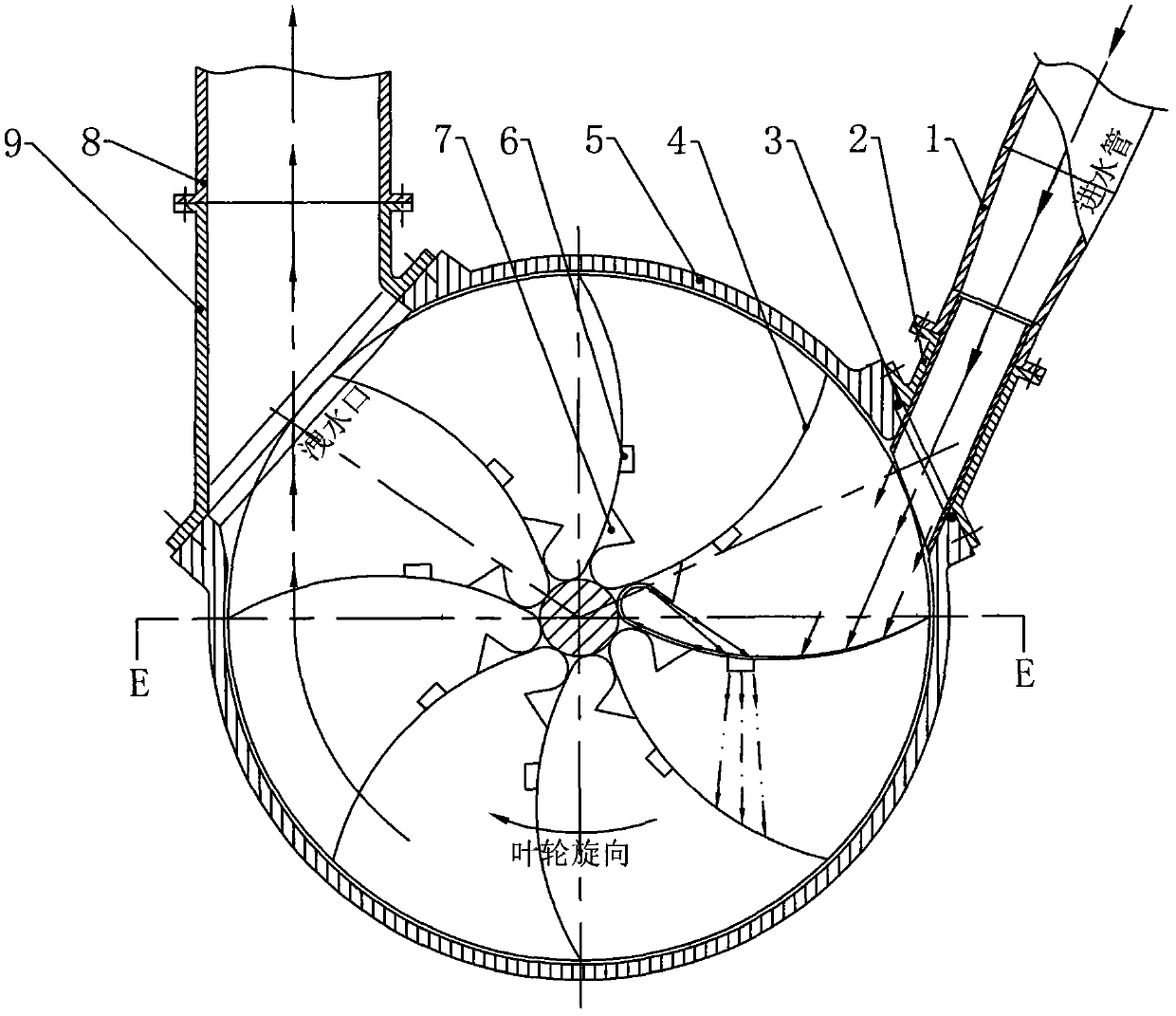

Secondary jet impulse water turbine

A two-stage injection and water turbine technology, which is applied in impact engines, hydroelectric power generation, mechanical equipment, etc., can solve the problems of water turbine vibration, shutdown, and interference with the movement rhythm of power water flow, etc., to achieve the effect of improving work ability and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The power water source forms a columnar water flow from the water inlet pipe (1) through the water inlet interface seat (2) and enters the inner cavity of the turbine, and performs a first-stage jet impact on the boat-shaped blade (4) [as indicated by the arrow in the figure] to drive the impeller to rotate. When the power water source rushes along the front of the blade, it meets the preset secondary injection port (6) [that is, the split hole]. Part of the water flows into the split hole, and the other part of the water continues to rush forward and rushes into the bottom of the boat-shaped blade. The terminal, under the guidance of the deflector (7), flows back and is "introduced" into the split hole [that is, the second-level injection port (6)], and merges with the incoming water flow to form the second-level jet, which is aimed at the front-level blade The impact is carried out, and the continuous jet impact produced by the first-stage jet and the second-level jet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com