Sealing valve

A technology of sealing valve and valve plate, applied in the field of sealing valve device, can solve the problems of equipment maintenance difficulty, hidden danger of equipment safety, deformation of driving arm, etc., and achieve the effects of simple and reasonable structure, good stress conditions, and reduced manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

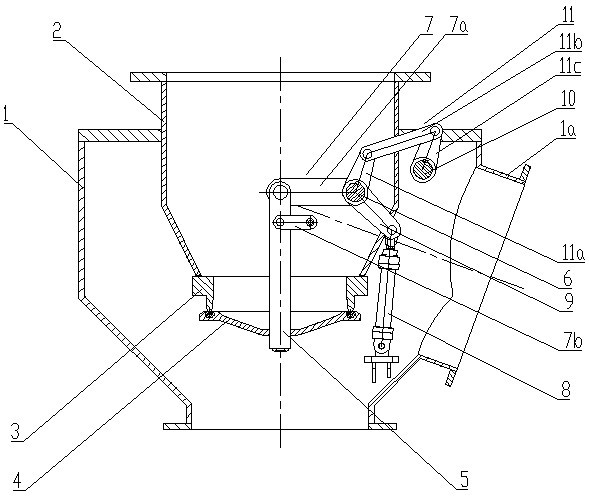

[0031] Such as Figure 1-Figure 5 As shown: the sealing valve of this embodiment includes a box body 1, a cylinder body 2 whose outlet end extends into the box body 1, a valve seat 3 fixedly arranged at the outlet of the cylinder body 2, and a cover for sealing on the valve seat 3 The functioning valve plate 4 and the valve plate opening and closing device for controlling the action of the valve plate 4, the valve plate opening and closing device includes a U-shaped transmission arm 5, which is coaxially and symmetrically arranged on both radial sides of the cylinder body 2 in a rotational fit manner Two valve plate drive shafts 6 on the box body 1, two drive cranks 7 symmetrically arranged on both radial sides of the cylinder body 2 and a driving device for driving the drive crank 7, the valve plate drive shaft 6 passes through the bearing The rotation fit is arranged on the box body 1, and the radial sides of the cylinder body 2 are preferably the two sides of the plane pass...

Embodiment 2

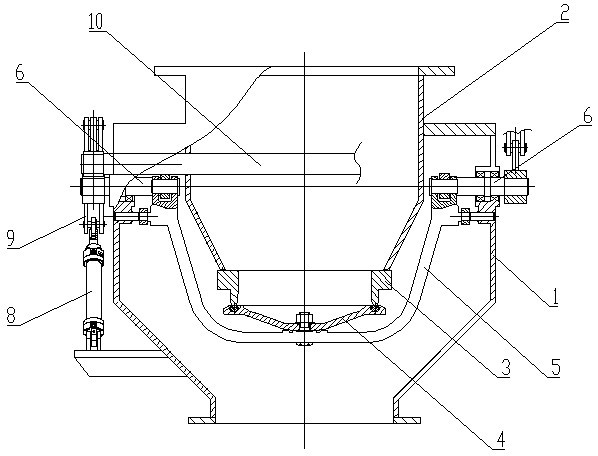

[0035] Such as Figure 6-Figure 8 As shown: the difference from Embodiment 1 is that one end of the driving crank 9 is hinged to the reciprocating output end of the hydraulic cylinder 8, and the other end is fixedly matched with the synchronous shaft 10 along the circumferential direction, so that the synchronous shaft 9 produces reciprocating rotation, driving two The valve plate driving half shaft 6 performs synchronous reciprocating rotation to realize the opening and closing of the valve plate 4 .

Embodiment 3

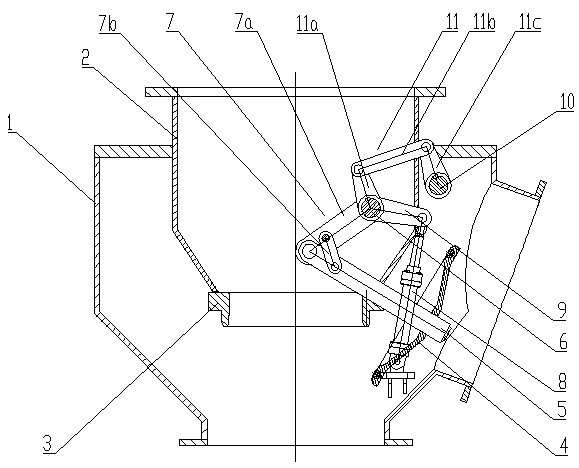

[0037] Such as Figure 9 , Figure 10 and Figure 11Shown: The difference from Embodiment 1 is that the synchronous device is removed in the structure of Embodiment 1, and two sets of driving devices are used to drive the two valve plate transmission half shafts 6 respectively, and the hydraulic cylinders 8 of the two driving devices are controlled to act synchronously , realize the synchronous reciprocating rotation of the two valve plate transmission half shafts 6, and realize the opening and closing of the valve plate 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com