Tea enzyme denaturing method and device thereof

A technology for killing green and tea leaves, which is applied in the direction of tea treatment before extraction, can solve the problems of increasing the difficulty of dehydration process, and achieve the effect of wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

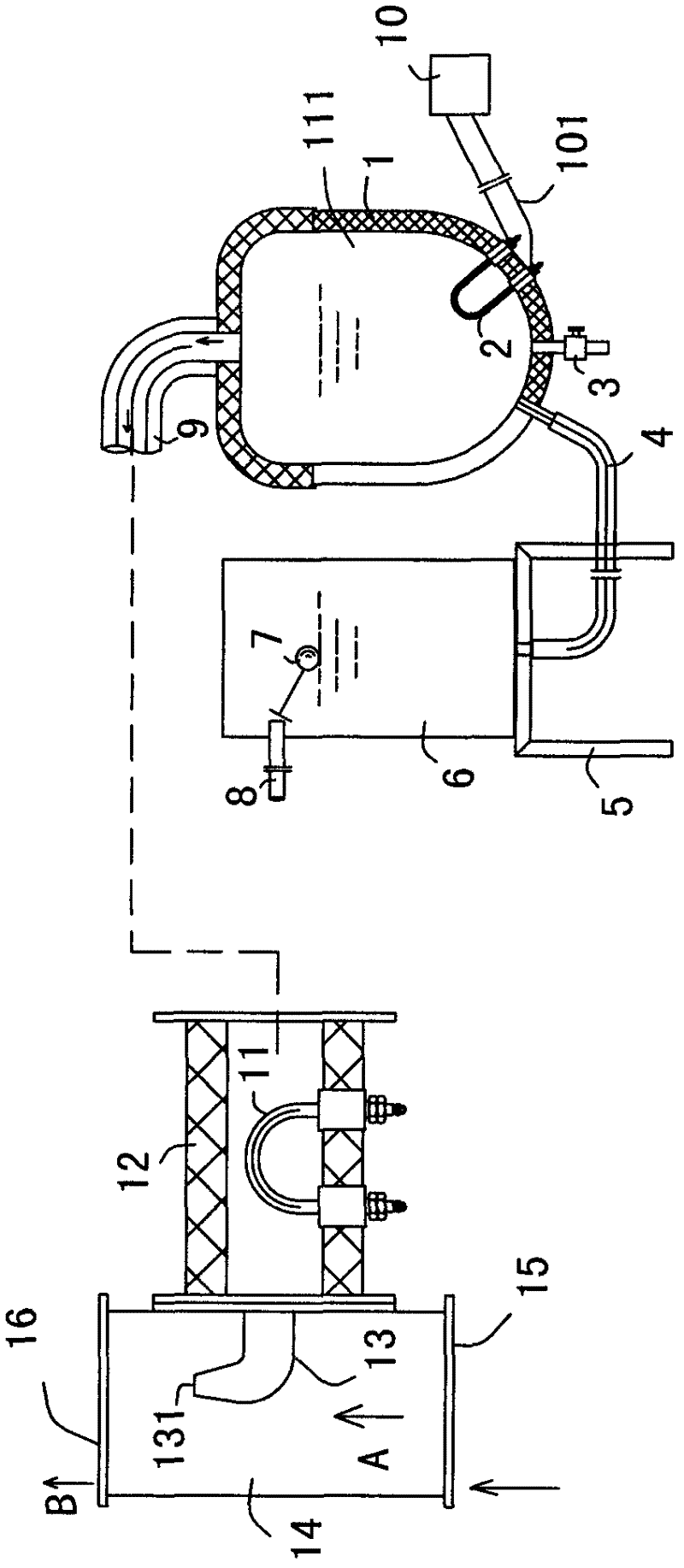

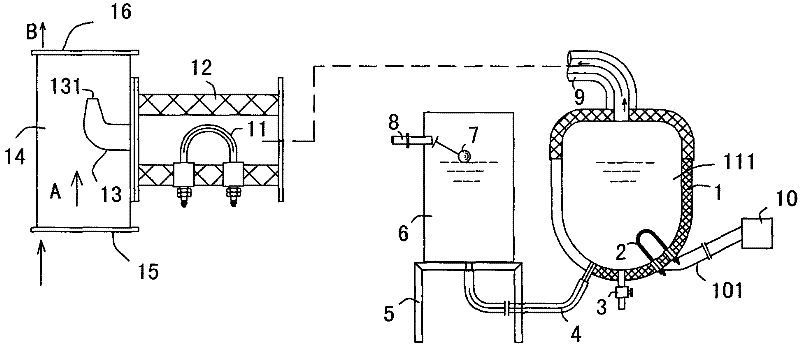

[0013] The process steps of this method for tea green removal are as follows: in a pressureless state, inject hot air into the green removal container, and adjustably add high-temperature steam into the hot air, and use the mixed medium of hot air and high-temperature steam to complete green removal.

[0014] As the tea greening device used in the above method of tea greening, the greening assembly and the hot blast stove assembly can use prior art equipment, and the main part of the greening assembly is a cavity for receiving the high-temperature hot air generated by the hot blast stove assembly, such as a drum type greening machine The drum is used to complete the greening process of fresh leaves of tea with high temperature hot air as the greening medium. The main function of the hot blast stove assembly is to generate high-temperature hot air de-encapsulation medium, and transport the de-encapsulation medium to the de-encapsulation component through the hot air pipe. Since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com