Dark tea processing method

A processing method and technology for dark tea, applied in the field of food processing, can solve the problems of extensive tea processing, unstable quality, and large gap between quality and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

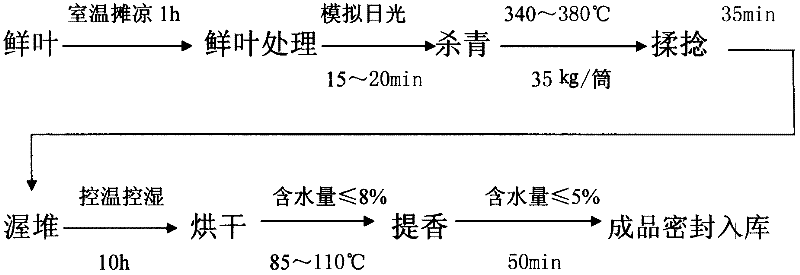

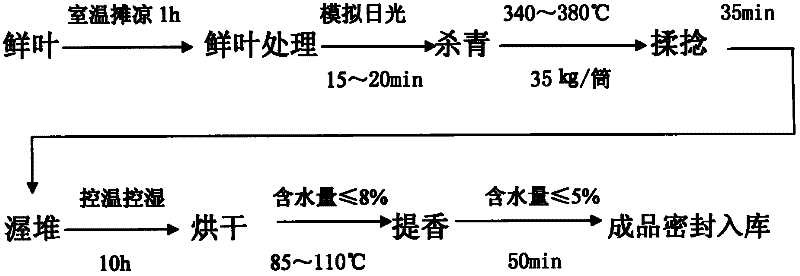

[0022] combine figure 1 The process flow chart of the present invention, the production process of the present invention is as follows:

[0023] ①Fresh leaves: Use one-bud two-leaf, three-leaf pair and single leaves with the same tenderness, remove thick old leaves and lignified tea stems, and let the fresh leaves cool at room temperature for 1 hour after entering the factory.

[0024] ②Fresh leaf treatment: carried out in the self-made fresh leaf treatment workshop. The room requires sealing and heat preservation. The temperature is controlled by a dedicated or household air conditioner, the humidity is controlled by a humidity machine, and infrared heating lamps are used to simulate sunlight treatment.

[0025] Technical indicators: temperature 21-24°C, humidity 80-85%, fresh leaf processing time is related to fresh leaf picking season, weather and workshop capacity, generally within the control temperature and humidity range, simulate sunlight for 15-20 minutes to make fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com