Directional cracking device for coal mines

A directional fracturing and coal mine technology, applied in the fields of mining fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of water gun detachment, drilling destruction, drilling, etc., to achieve easy production and processing, and improve work efficiency , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

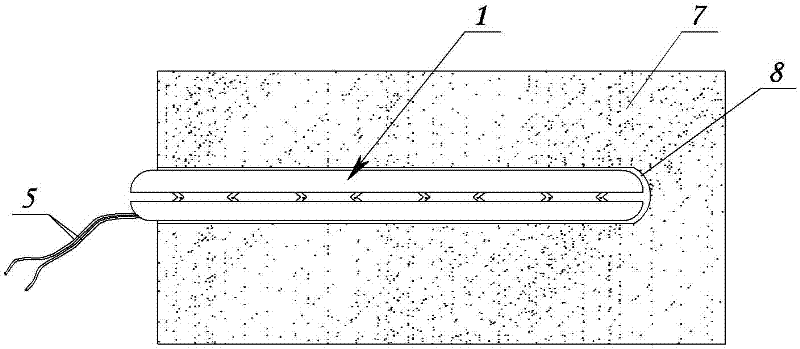

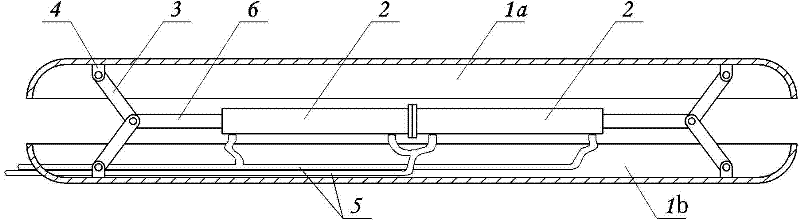

[0016] Embodiment one: see figure 1 , figure 2 The directional fracturing device 1 for coal mines comprises two interlocking strip arcuate support base plates 1a and 1b, at least a pair of lying hydraulic cylinders 2 are arranged between the two support base plates, and the paired two hydraulic cylinders The root of each hydraulic cylinder is butted, and the end of the piston rod of each hydraulic cylinder is symmetrically hinged with a push rod 3, and the inner surface of the strip-shaped arc-shaped support plate is provided with a hinge ear 4, and each push rod 3 is hinged on the corresponding hinge ear 4 through a pin shaft. . The oil inlet pipe of each hydraulic cylinder is connected with the total oil inlet pipe, and the oil outlet pipe of each hydraulic cylinder is connected with the total oil outlet pipe.

Embodiment 2

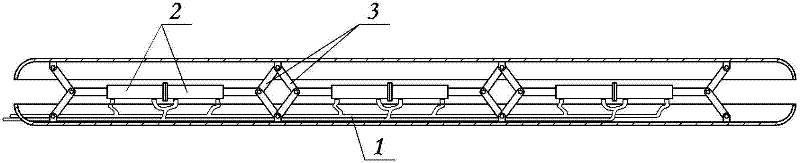

[0017] Embodiment two: see figure 1 and image 3 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that there are many pairs of horizontal hydraulic cylinders 2, and the push rods 3 of adjacent hydraulic cylinders are jointly hinged on the same hinge ear 4, which can improve the middle part. top force.

Embodiment 3

[0018] Embodiment three: see figure 1 and Figure 4 , The content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that each hinge ear is evenly distributed and the inner sidewall of the strip-shaped arcuate support base plate, and the paired horizontal hydraulic cylinders 2 are distributed at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com