Non-explosive tunnel excavation construction method

A construction method and non-explosive technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of low work efficiency, uneconomical, large equipment investment, etc., and achieve the effect of low cost, less labor, and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described below in conjunction with the accompanying drawings and embodiments, and this example is only illustrative, rather than limiting the invention.

[0026] 1. Brief introduction of the tunnel:

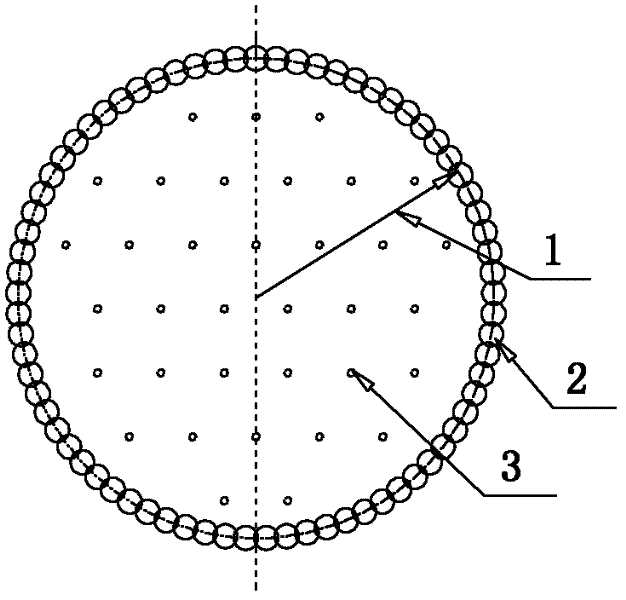

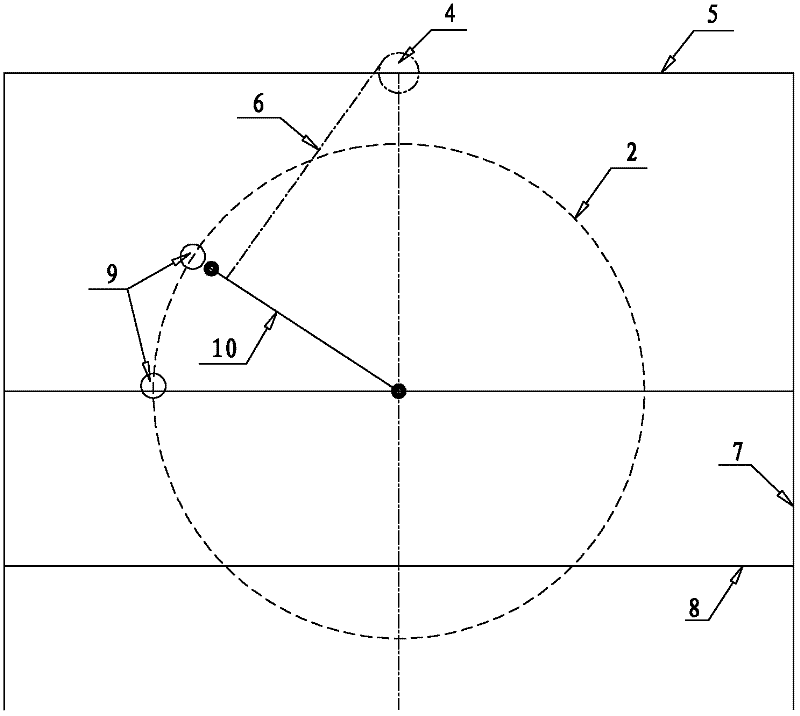

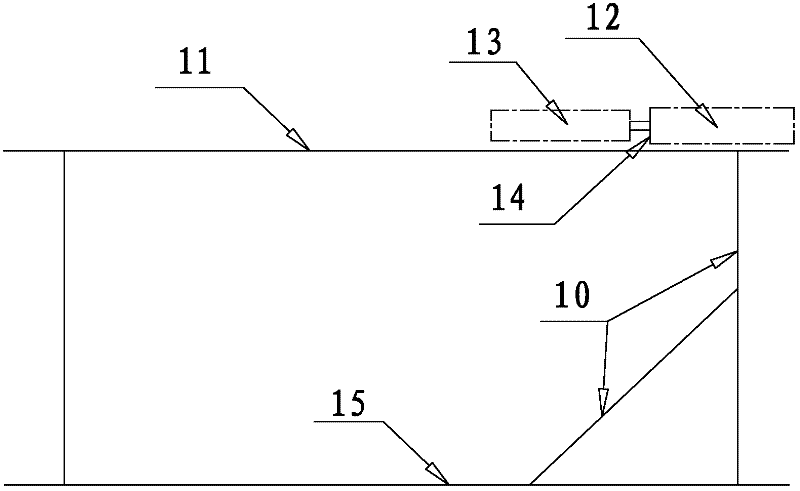

[0027] Changhongling Tunnel (13299m) is the second extra-long tunnel of Yuli Railway, and the exit of the tunnel is located in Jiangchi Town, Fengdu County, Chongqing City. The tunnel passes through Jiangchi Town at section DK183+050~DK183+350, with shallow buried depth and dense houses on the surface. The construction of DK183+000~DK183+400 section adopts controlled blasting, and the surface vibration velocity is controlled to be no more than 1.5cm / s. The geology of the blast control section is J3s sandstone. The formation is generally monocline, with a small inclination angle, joint spacing of 0.5-2m, and extension length of 2-5m. The section span is 13.82m and the height is 11.82m. The excavation height of the full section is 9.98m (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com