Variable area type differential pressure flowmeter adopting variable area type differential pressure flow structure

A differential pressure flowmeter and variable area technology, applied in the field of variable area differential pressure flow structure and variable area differential pressure flowmeter, can solve the problems of not being completely solved, large permanent pressure loss, etc., to improve the range ratio High, easy to install, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

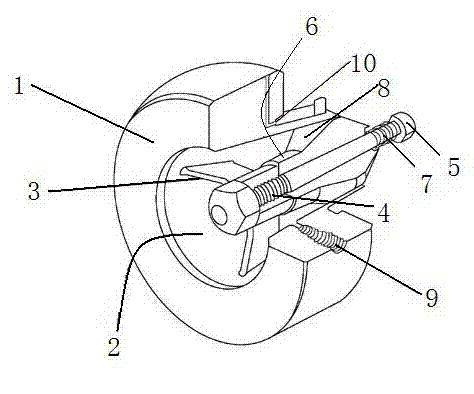

[0028] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

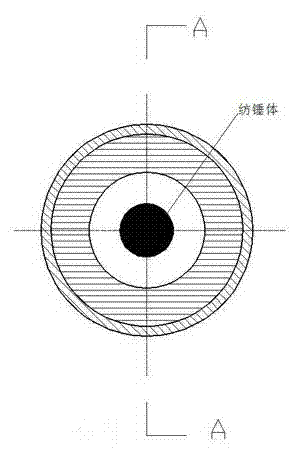

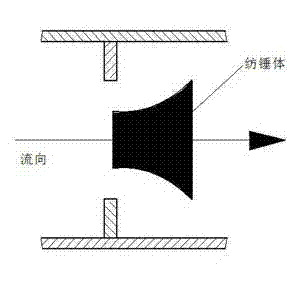

[0029] Research of the present invention is based on following theory: as figure 1 and figure 2 As shown, when the fluid flows through the throttling member, a pressure difference between front and back is formed. This differential pressure causes the spindle to displace by a distance of , the diameter of the outer contour of the spindle is . Under the action of the restoring force of the spring, the spindle body moves for a certain distance and then comes to rest, reaching a state of equilibrium, and the differential pressure is equal to the stiffness coefficient of the spring and itinerary The product of is:

[0030] —— ( = coefficient of restitut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com