Method for limiting distribution and scheduling for solving machine changing problem

A scheduling method and problem-solving technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as frequent machine changes, loss of equipment utilization, unreasonable machine changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

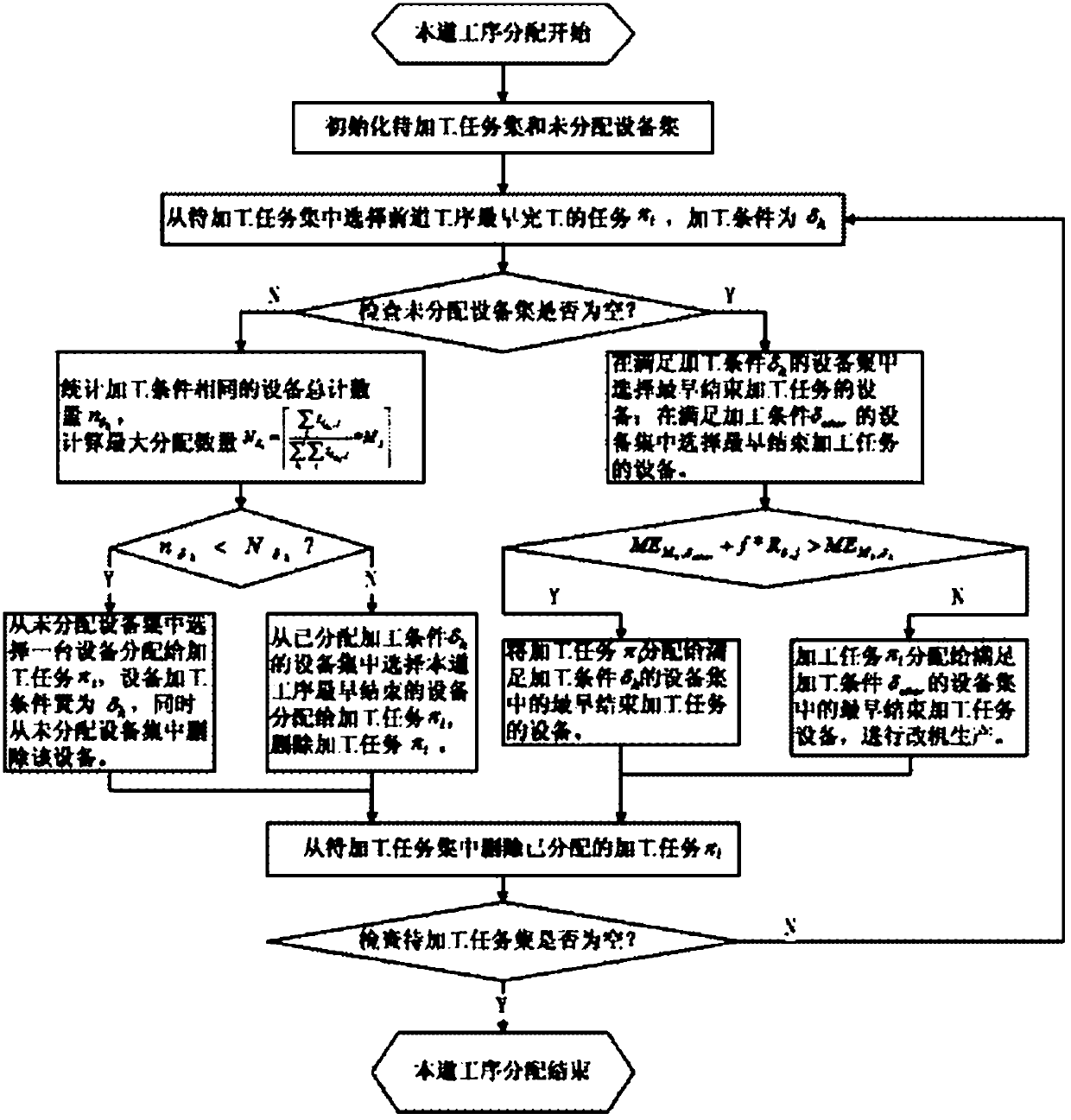

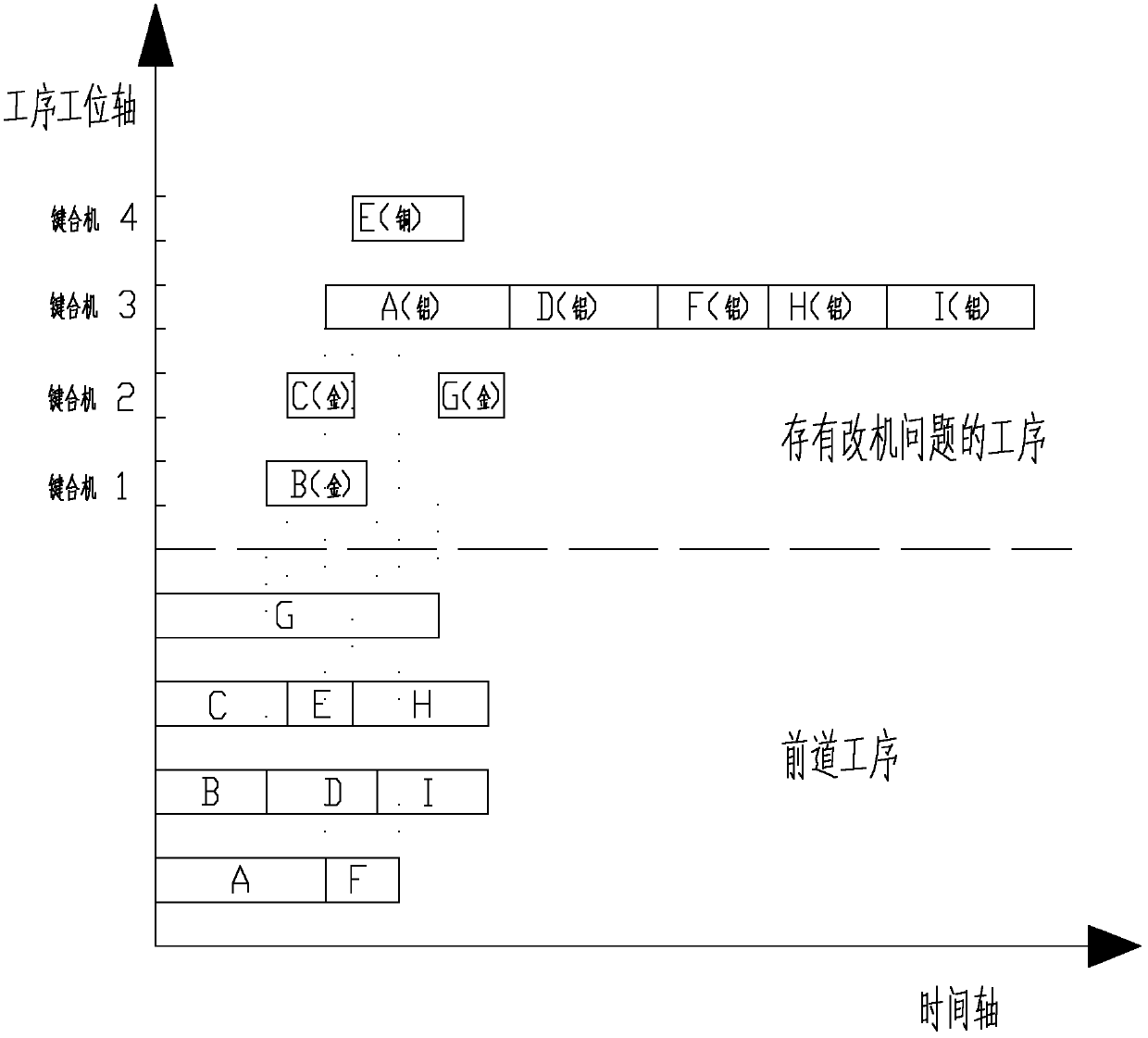

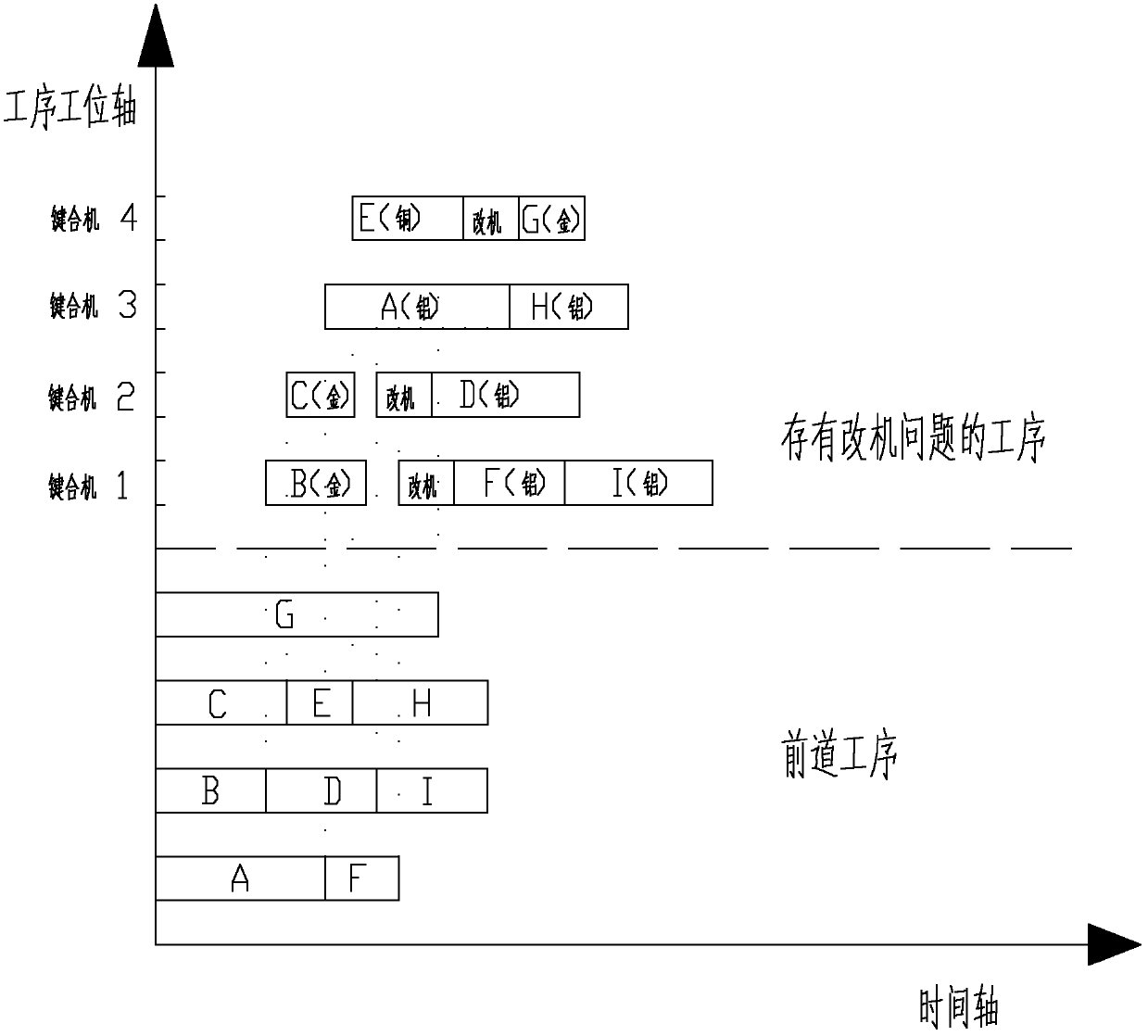

[0052] The overall flow chart of the limited allocation and scheduling method invented by the present invention for the problem of machine modification is as follows: figure 1 shown. Taking the bonding process in the semiconductor back-end manufacturing process as an example to illustrate, figure 2 , image 3 , Figure 4 Graphs of the results of different scheduling methods. in, figure 2 An example diagram of scheduling without limited equipment allocation and machine modification; image 3 It is an example diagram of scheduling without limited allocation of equipment and arbitrary machine modification; Figure 4 An example diagram of the limited allocation scheduling proposed by the present invention. Comparing these three figures, it can be seen that after using the limited allocation scheduling algorithm of the present invention, n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap