Method for modelling and simulating one-sided welding two-sided forming process by grids

A single-sided welding double-sided, forming process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

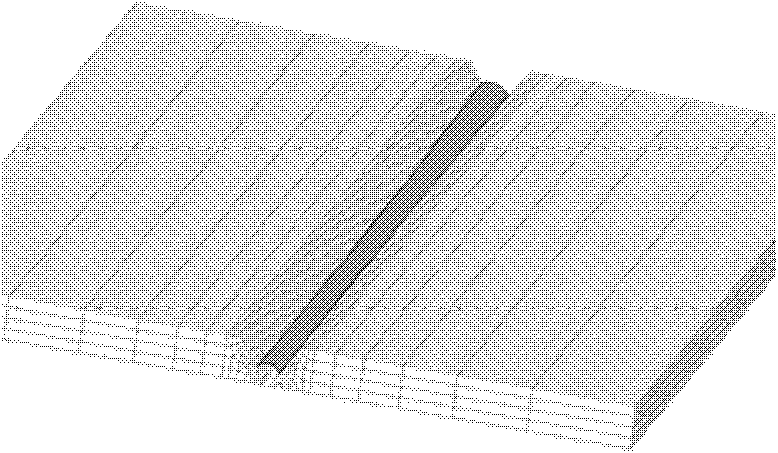

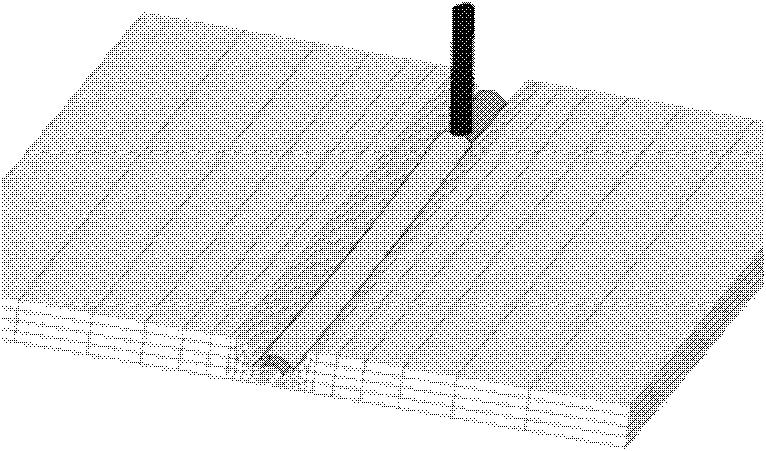

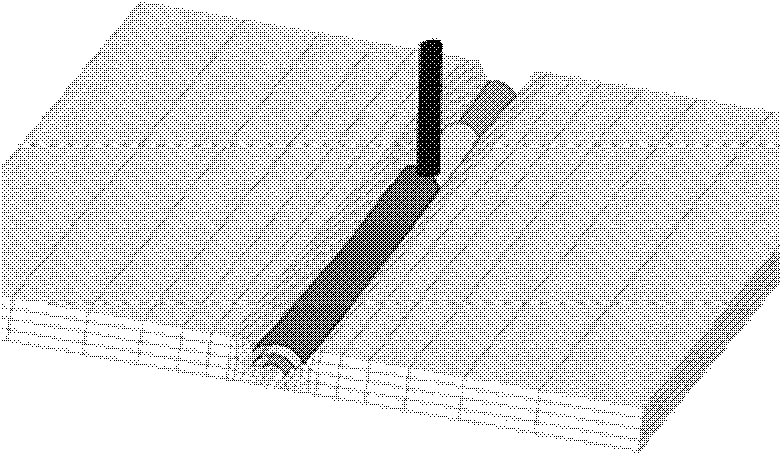

[0049] The most critical technology in the simulation of single-sided welding and double-sided forming has two parts: one is to draw a reasonable grid so that it can reflect different welding layers (priming layer, filling layer, cover layer); the other is a reasonable mathematical function , using it to control the movement of the vertices of the triangular mesh, and under the joint action of physical factors such as light and material, and visual and auditory factors such as arc light, splash, sound, etc., the molten pool weld can be realistically simulated. The invention adopts a multi-layer grid method to realize the simulation of the welding layer; the method of combining multiple heat source models is used to obtain the growth function of the molten pool depression and the reinforcement of the welding seam.

[0050] 1. Multi-layer grid method

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com