Piezoelectric speaker based on piezoelectric cantilever beam

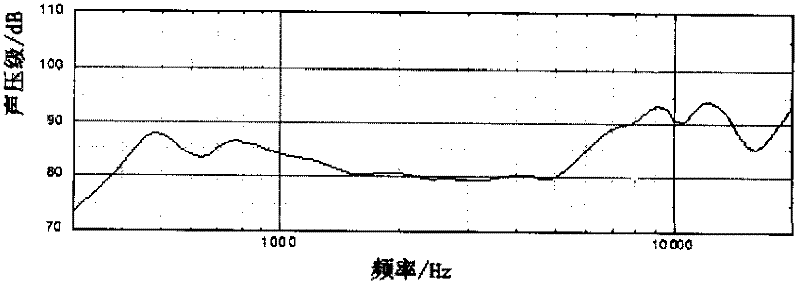

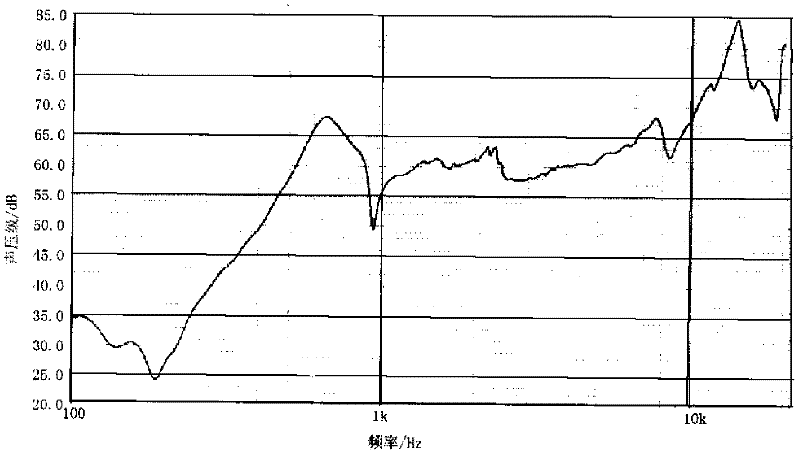

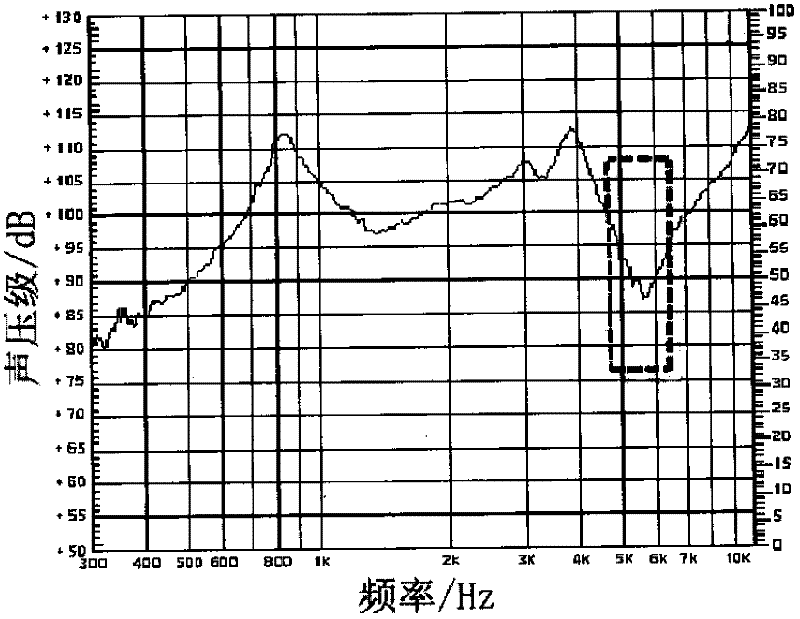

A technology of piezoelectric speakers and cantilever beams, applied in the direction of piezoelectric/electrostrictive transducers, resonant transducers, etc., can solve the problems of low sound pressure output, small amplitude of vibrating plate, high resonance frequency, etc., and achieve sound output frequency The effects of smooth response, measured value improvement, and excellent low-frequency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Figure 4 It is a sectional view of Embodiment 1 of the present invention; Figure 5 For Embodiment 1 of the present invention, the sectional view of the front cavity shell and the rear cavity shell is hidden (only the section is shown); Figure 6 It is an explosion diagram of Embodiment 1 of the present invention; Figure 7 It is an exploded view of the embodiment 1 of the present invention with the front cavity shell and the rear cavity shell hidden. The upper layer piezoelectric ceramic sheet 2 and the lower layer piezoelectric ceramic sheet 3 with opposite polarization directions are bonded on both sides of the middle layer fiber sheet 1 to form a piezoelectric cantilever beam. The middle layer fiber sheet 1 at one end of the piezoelectric cantilever beam structure and the stainless steel outer frame 8 Bonding forms the fixed end of the cantilever beam, and leads the electrode 4 from the fixed end; the movable end of the piezoelectric cantilever beam is connected ...

Embodiment 2

[0029] Figure 8 It is a top view of Embodiment 2 of the present invention (rear cavity shell is hidden); Figure 9 It is an explosion diagram of Embodiment 2 of the present invention. The basic structure is the same as that of Embodiment 1, but the difference is the double piezoelectric cantilever beam structure. The two fiber sheets at one end of the piezoelectric cantilever structure are respectively bonded to two parallel frames of the stainless steel outer frame 8 to form a fixed end of the cantilever, and the electrodes 4 of the multilayer piezoelectric ceramic sheet are drawn out from the fixed end. The fiber sheets at the movable end of the piezoelectric cantilever beam structure are respectively connected to the vibrating sheet 5 made of stainless steel with a thickness of 150 microns through the connecting block 6 made of ABS plastic, and the connecting block consists of 6 blocks. The stainless steel vibrating piece 5 is bonded to the stainless steel frame 8 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com