Double movable-coil servo type ultra-low frequency rotational vibrating table

A servo-type, ultra-low-frequency technology, which is applied in the direction of vibrating fluid, can solve the problems of expensive vibration table, high minimum measurement frequency, high calibration cost, etc., and achieve the effect of simple structure, low manufacturing difficulty and good low-frequency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

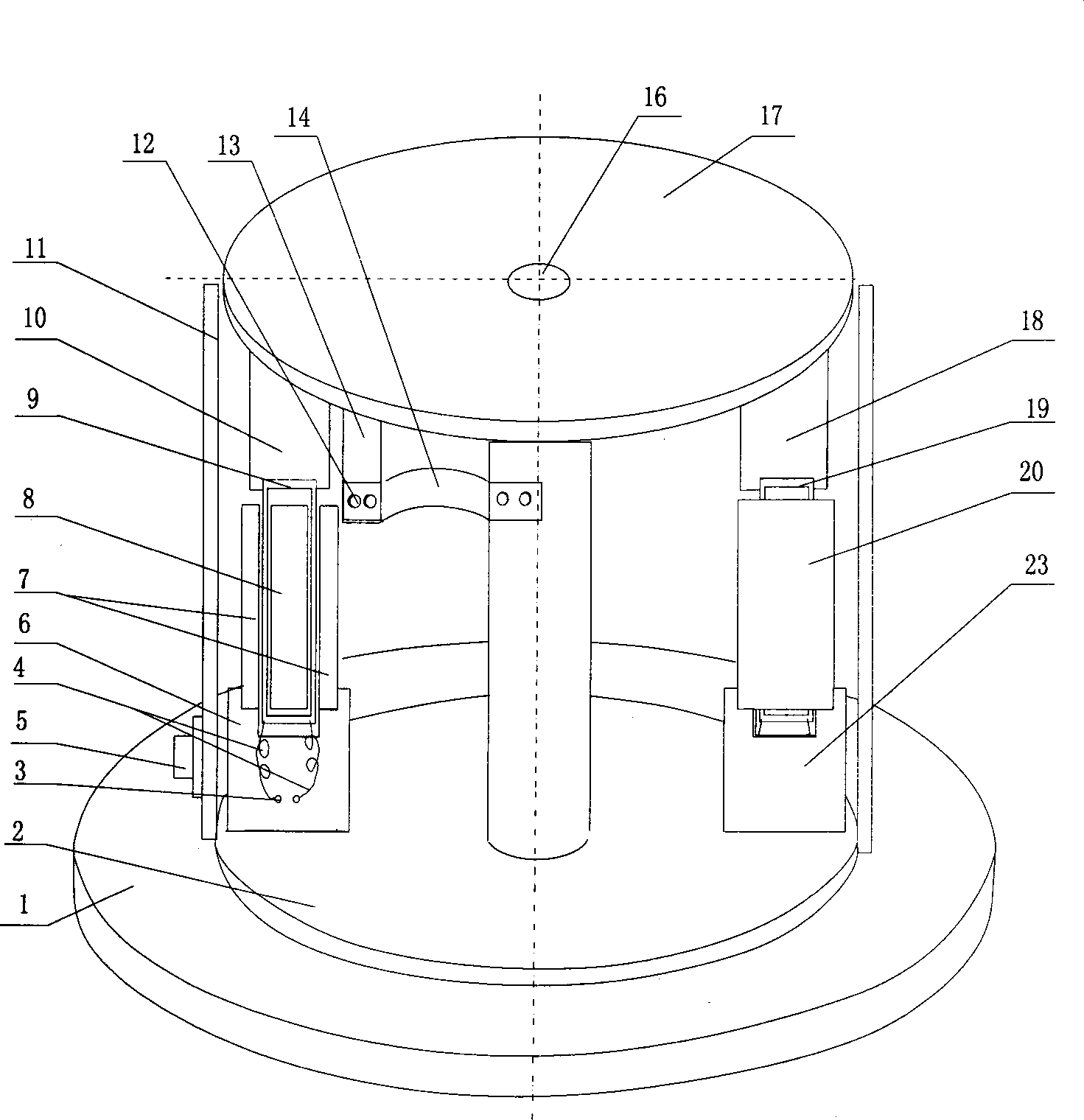

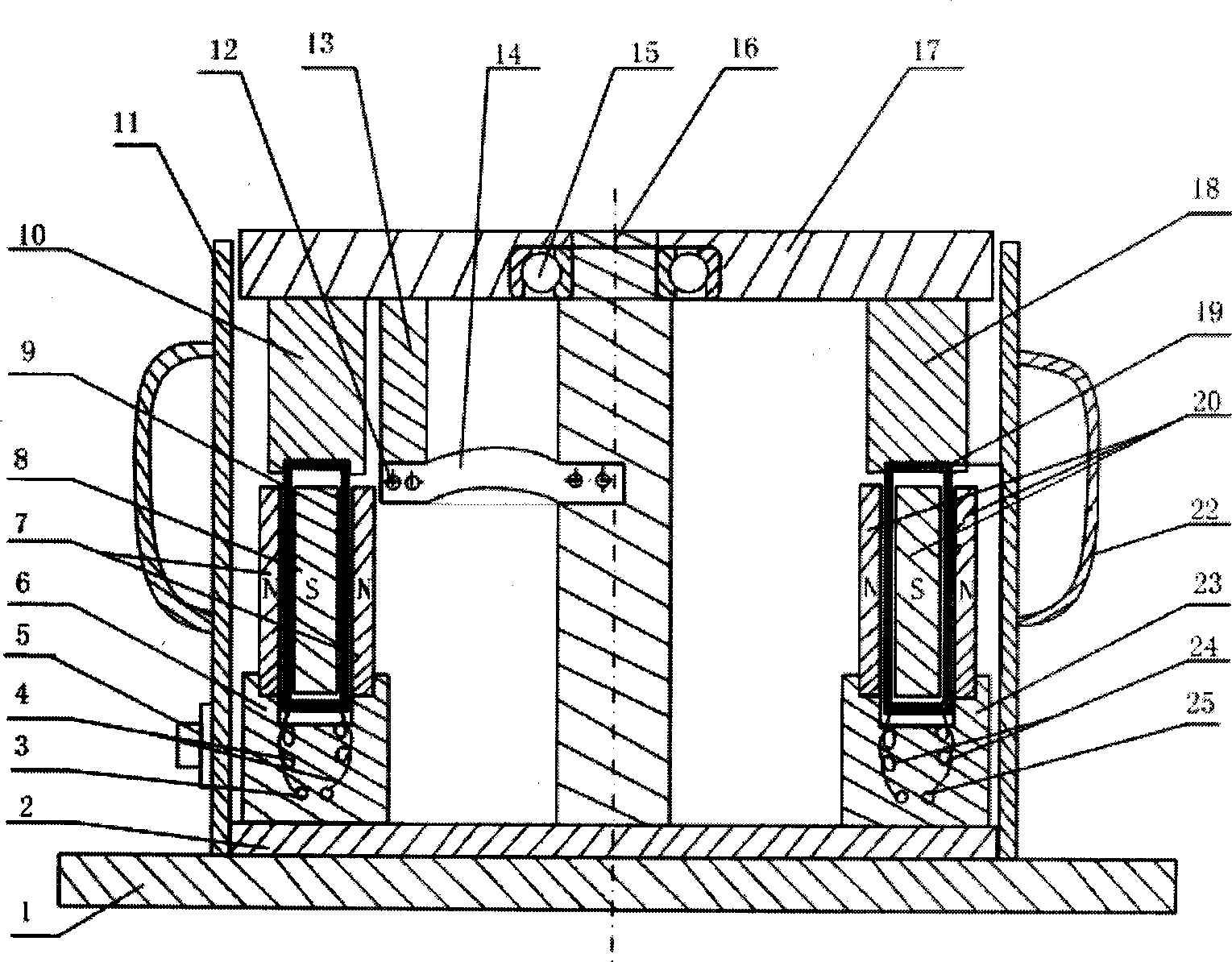

[0015] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

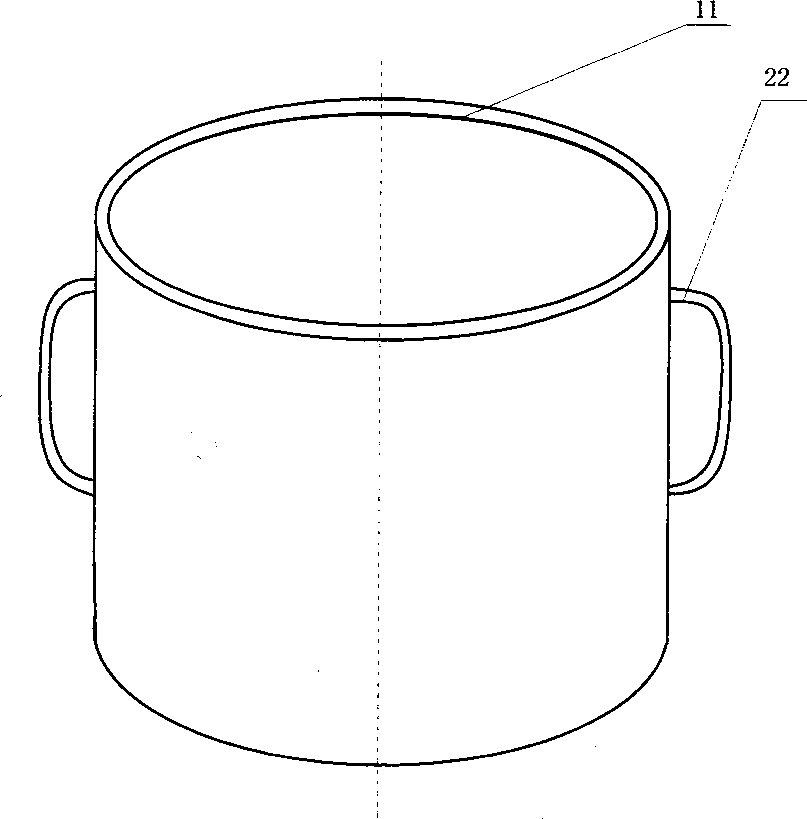

[0016] Depend on Figure 1-Figure 6 It can be seen that the present invention includes a base plate 2 and a housing 11. The base plate 2 is provided with a turntable, a drive system and a feedback system. The turntable includes a vertical shaft 16, and the lower end of the vertical shaft 16 is installed on the base plate 2. The upper end of the vertical shaft 16 passes through the The precision bearing 15 is connected to the circular rotating table top 17, and the shaft section of the vertical shaft 16 located below the precision bearing 15 is fixedly connected to one end of the spring leaf 14, and the other end of the spring leaf 14 is connected to the circular rotating table top 17 through a spring connector 13. The drive system includes a signal source 26, a drive coil 19, and a magnetic circuit 20. The upper end of the drive coil 19 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com