Sintered ceramic and substrate comprising same for semiconductor device

A technology of sintered body and ceramics, applied in semiconductor devices, semiconductor/solid-state device parts, transportation and packaging, etc., can solve the problems of inability to manufacture DBOC substrates, inability to apply heat dissipation substrates for power modules, low thermal conductivity, etc. Effects of thermal stress relaxation, high mechanical strength, and high thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Hereinafter, the ceramic sintered body according to Example 1 of the present invention will be described.

[0121] The ceramic sintered body according to Example 1 is a ceramic sintered body used as an insulator for a power module substrate used in automobiles, air conditioners, industrial robots, business elevators, household microwave ovens, Electronic equipment such as IH rice cookers, power generation and transmission (wind power generation, solar power generation, fuel cells, etc.), electric railways, UPS (uninterruptible power supply), etc.

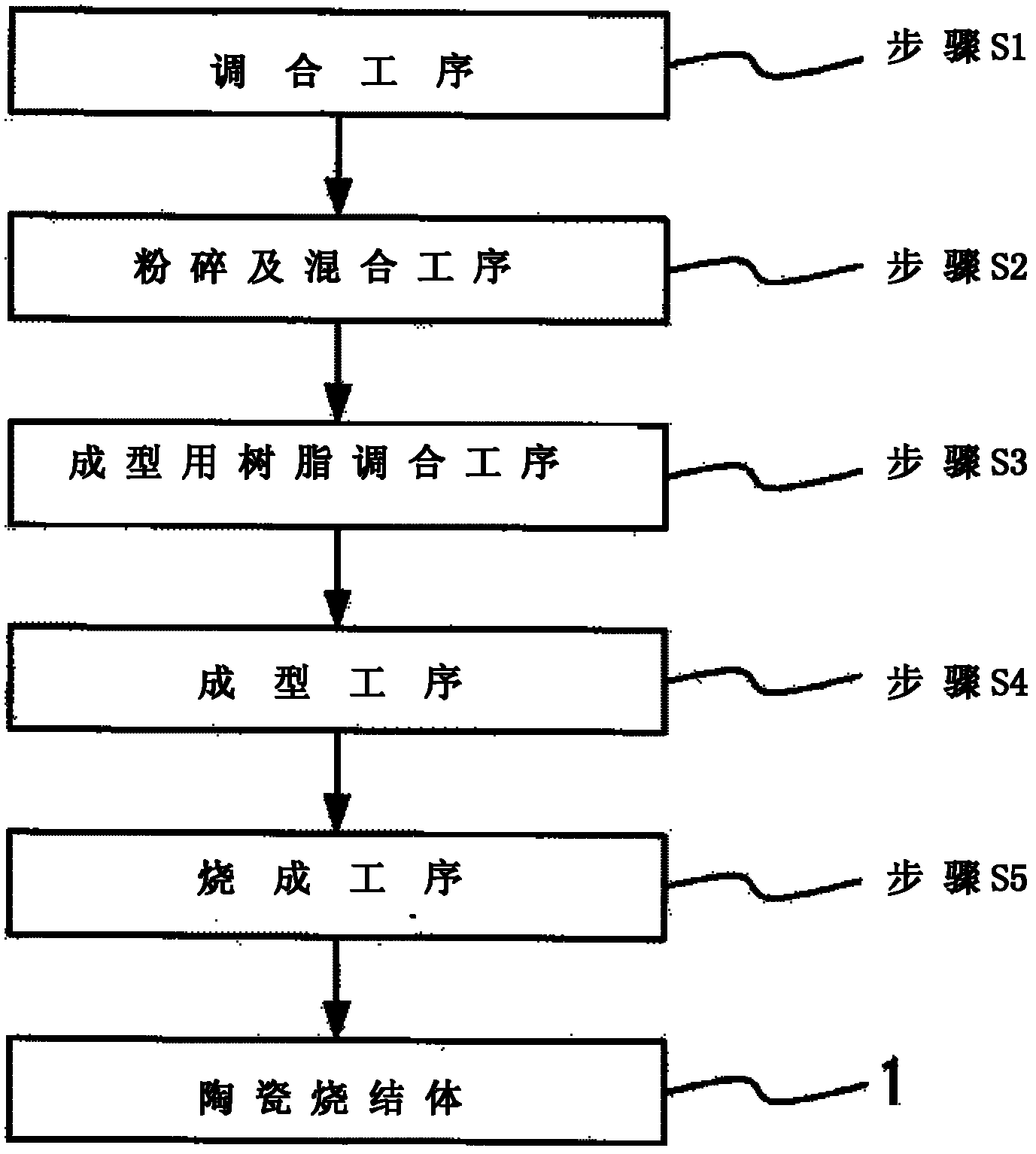

[0122] First, compare figure 1 The method of manufacturing the ceramic sintered body according to Example 1 will be described in detail.

[0123] figure 1 It is a flow chart showing the manufacturing method of the ceramic sintered body concerning Example 1.

[0124] Such as figure 1 As shown, in the production of the ceramic sintered body 1 according to Example 1, first, alumina, partially stabilized zirconia, and magnesi...

Embodiment 2

[0198] Next, a semiconductor device substrate according to Embodiment 2 will be described with reference to FIG. 8 .

[0199] 8( a ) is a cross-sectional view of a semiconductor device substrate according to Example 2, and FIG. 8( b ) is a cross-sectional view of a semiconductor device using the semiconductor device substrate.

[0200] Regarding the semiconductor device substrate 2 according to the second embodiment, the copper plate 4 is disposed on at least a part of the front surface and the back surface of the ceramic substrate 3 composed of the ceramic sintered body 1 according to the above-mentioned first embodiment. More specifically, the copper plate 4 forming the power transmission circuit is arranged on the surface of the flat ceramic substrate 3, and after the flat copper plate 4 is arranged on the back surface of the ceramic substrate 3, it is heated under a nitrogen atmosphere at a temperature of 1070 to 1075°C. After about 10 minutes, a Cu—O eutectic liquid phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com