Bio-absorbable medical compound material and preparation method thereof

A composite material and biological technology, applied in the fields of bone trauma surgery, bone defect repair surgery, biomedical equipment, plastic and cosmetic medical equipment, can solve the problem of reducing the ability of fracture fixation, affecting imaging examination, chemotherapy of tumor patients, non-degradable absorption, etc. problems, to achieve the effect of improving strength and toughness, controllable degradation and absorption speed, and overcoming too high and too strong acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

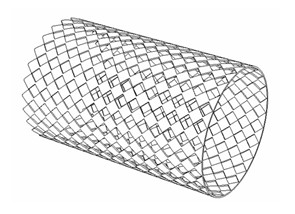

[0033] The preparation method of the bioabsorbable medical composite material is as follows: selecting a magnesium alloy wire or fiber with a suitable length and diameter as a reinforcing phase, weighing the corresponding weight of the magnesium alloy wire (or fiber) and polylactic acid according to the formula, Prepare a ceramic protective film on the surface of magnesium alloy wire (or fiber) by micro-arc oxidation method, and according to the arrangement and distribution requirements of the reinforcement phase in the matrix, the magnesium alloy wire or fiber with a ceramic protective layer on the surface is first oriented with a mold The arrangement is fixed, or the magnesium alloy wire or fiber is artificially woven into a two-dimensional grid or a three-dimensional tube grid, and fixed with a mold; secondly, the polylactic acid powder is directly mixed with the magnesium alloy wire or fiber until it is evenly prepared, and then The mixture is molded or extruded at 80°C to ...

Embodiment 1

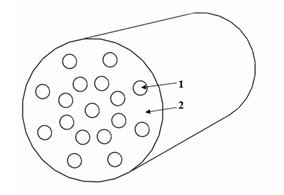

[0038] Seventeen AZ31B magnesium alloy wires with a diameter of 0.32mm and a length of 80mm were selected as the reinforcing phase, and 10g / L sodium silicate, 2g / L NaOH and 10g / L hydroxyapatite nanoparticles were used as the micro-arc oxidation electrolyte system. Magnesium alloy wire is immersed in it, 400V voltage is applied, and micro-arc oxidation treatment is carried out for 10 minutes, so that a layer of ceramic protective film rich in magnesium oxide, magnesium silicate and hydroxyapatite is formed on the surface in situ. Fix the reinforcing phase through two ends as follows figure 1 The orientation shown in the schematic diagram is arranged in the cavity of a 70mmxφ5mm mold. Weigh 1.7g of polylactic acid with a molecular weight of 200,000, heat it to 200°C to melt, then inject the solution into the mold cavity, mix the polylactic acid solution and magnesium alloy wire evenly, and mold it into a rod at 190°C. Finally, it is processed into orthopedic fixation devices su...

Embodiment 2

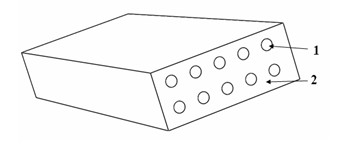

[0040] Select 10 MB8 magnesium alloy wires with a length of φ0.8mm and a length of 80mm as the reinforcing phase, and pass it through the micro-arc oxidation treatment method as shown in Example 1 to obtain a film layer rich in magnesium oxide, magnesium silicate, and hydroxyapatite . The magnesium alloy wire after micro-arc oxidation is fixed at both ends, arranged and fixed along the length direction of the mold cavity with a specification of 5mmx20mmx70mm, such as figure 2 As shown, the distance between the wires should be more than 1mm; take 8.7g of polylactic acid with a molecular weight of 200,000, heat it to 200°C and melt it, then inject the solution into the mold cavity, and mix the polylactic acid solution with the magnesium alloy wire. Uniform, molded at 190°C. Finally, it is processed into orthopedic fixation devices such as bone plates by ordinary machining methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap