Sheet tape-threading and locating and punching device and method

A technology for positioning punches and positioning holes, which is used in perforating tools, metal rolling, manufacturing tools, etc., and can solve the problem of the relative position of the rope hole and the reinforcing round steel being incorrect, the strip steel around the rope hole being torn, the point of force and the force Unequal problems, to avoid re-tear phenomenon, uniform force distribution, reasonable spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with the accompanying drawings.

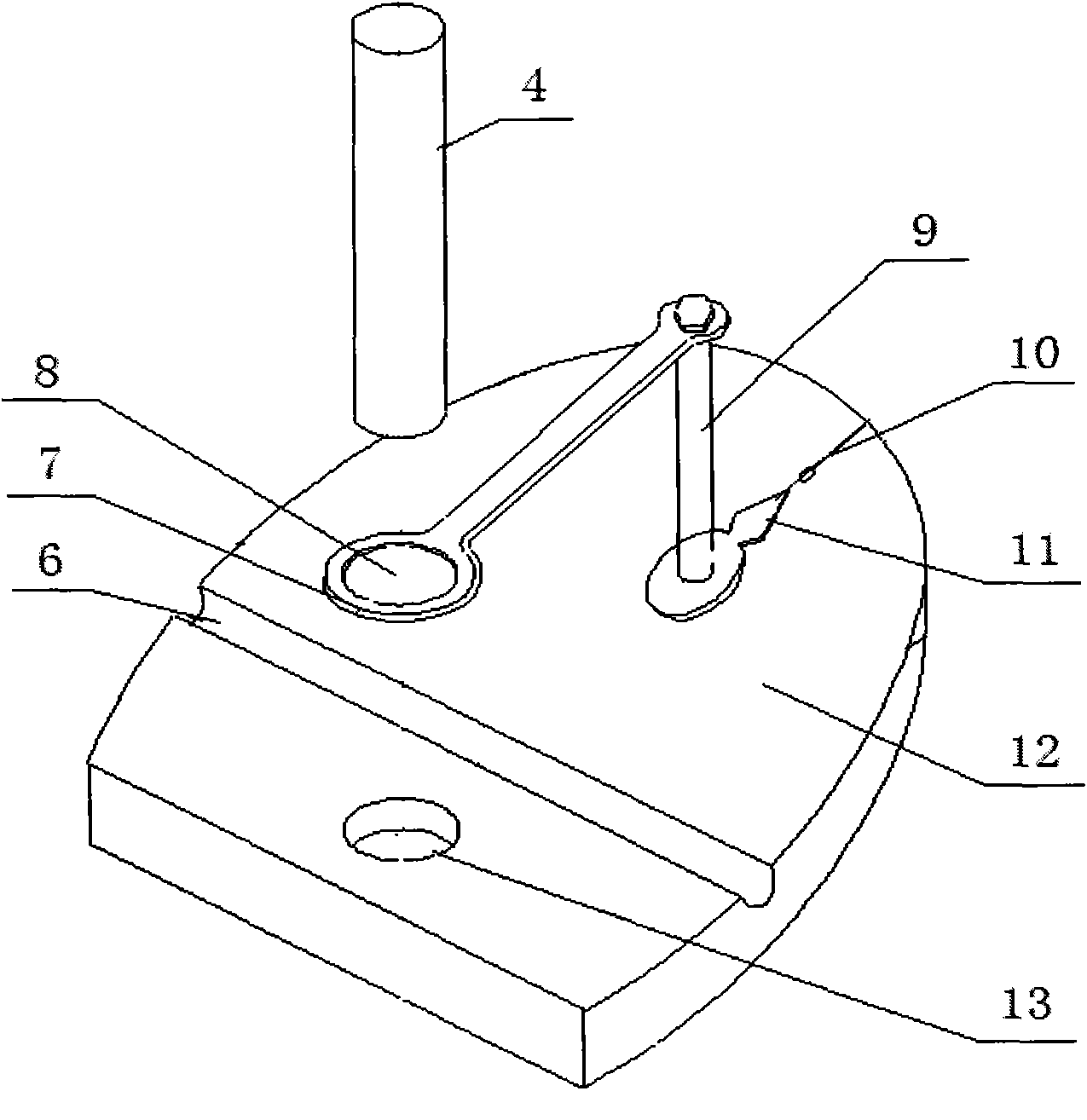

[0028] As can be seen from the accompanying drawings, the thin plate threading belt positioning punching device of the present invention is mainly composed of a stamping die, a punching chisel 4 and a positioner.

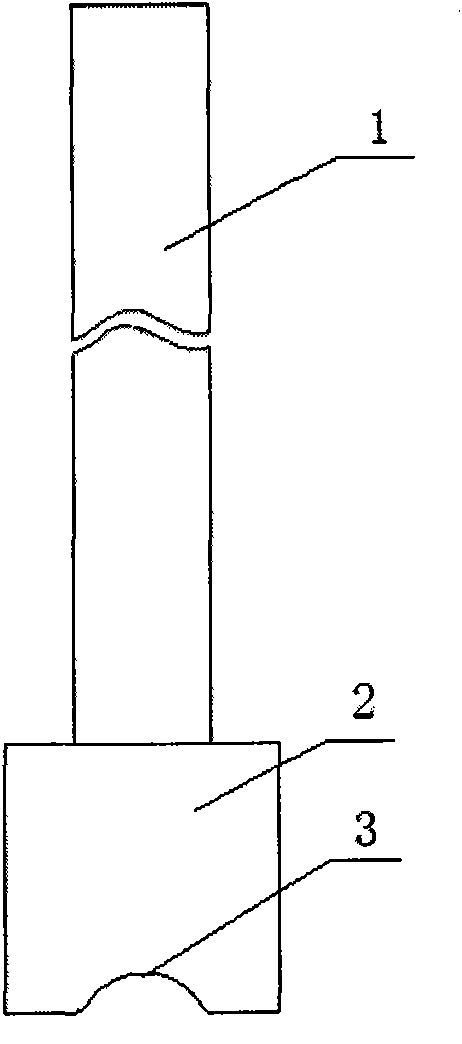

[0029] The stamping mold system is composed of an upper stamping rod 1 and a lower mold 2, that is, a stamping rod 1 is vertically welded in the middle of a cuboid mold 2, and a long arc-shaped groove 3 is processed along the lower part of the mold 2. . The mold 2 is made of 40×40×105mm square steel, and the total height of the stamping die is 200mm. The radius of the arc of the arc groove 3 is determined according to the diameter of the round steel in the punched steel sleeve, generally slightly larger than the radius of the round steel by 2mm.

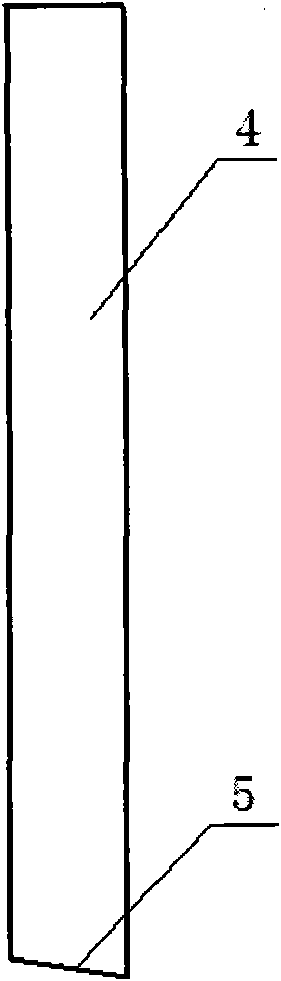

[0030] The punching chisel 4 is a cylinder, and the chisel head 5 at the lower end of the punching chisel 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com