Liquid discharge opening of die and casting die

A technology for casting molds and molds, which is used in casting molding equipment, molds, mold components, etc., can solve problems such as poor product quality, unstable process, and short life expectancy, and achieve long service life and reduce the amount of hot water. Mold, casting smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

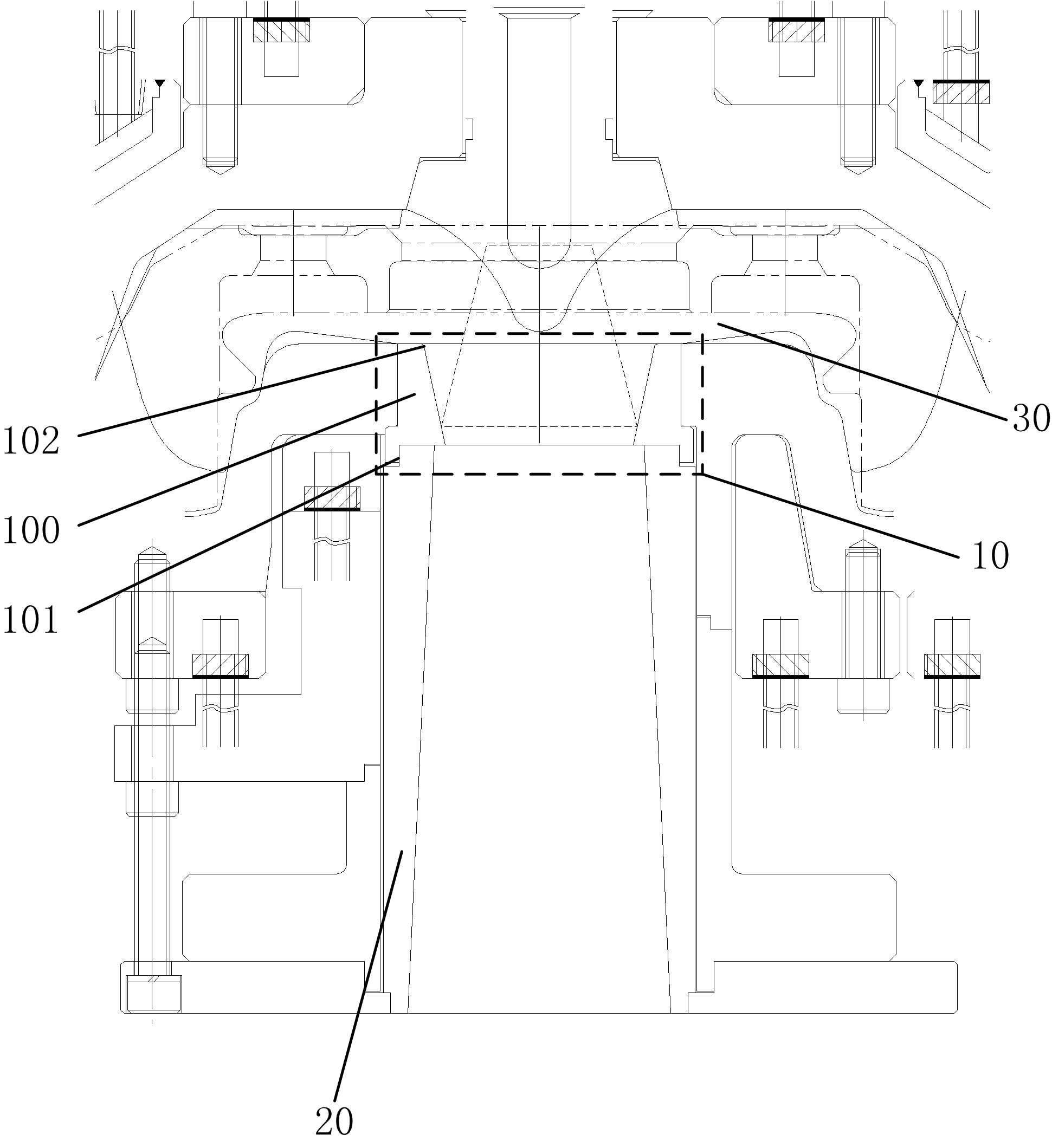

[0022] Next, in conjunction with the accompanying drawings, the specific embodiments of the mold mouth and the casting mold of the present invention will be described in detail.

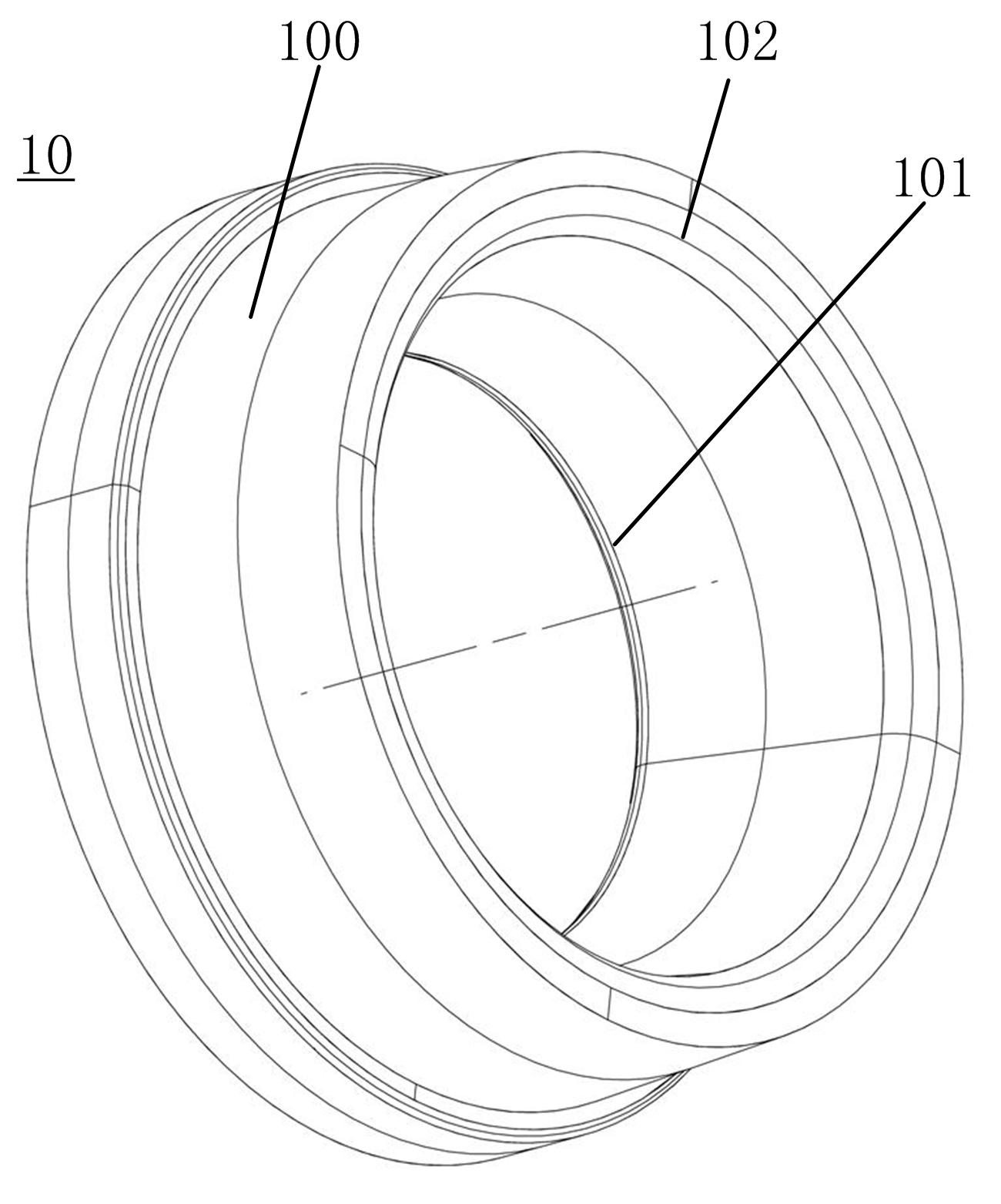

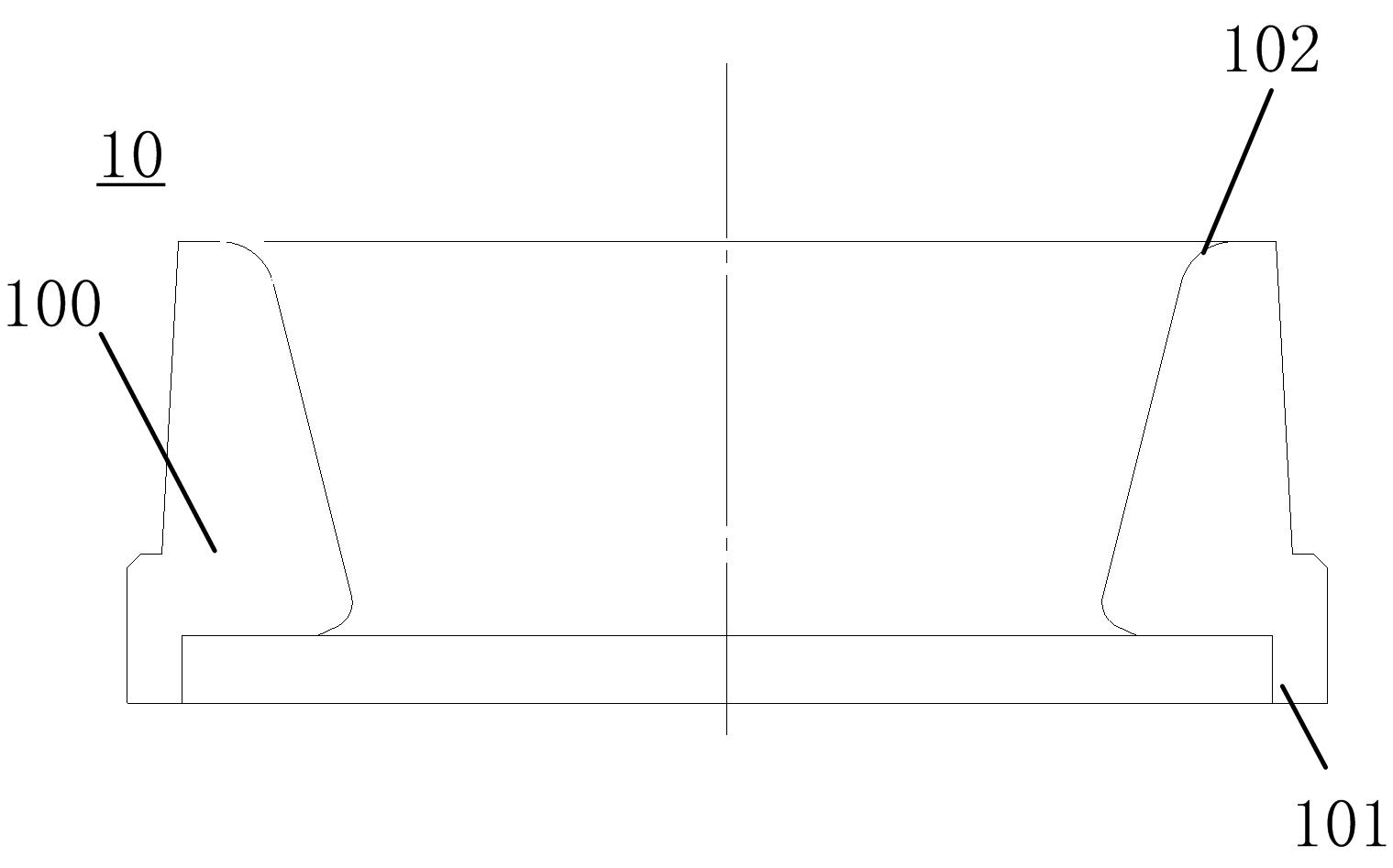

[0023] attached figure 1 Shown is a three-dimensional view of the mold opening 10 according to this specific embodiment, the mold opening is in the shape of a ring, with the attached figure 2 is attached figure 1 Sectional view along any diameter. Reference attached figure 1 and attached figure 2 , the shown mold mouth 10 includes an inner bayonet 101 with a body 100 sleeved to a ceramic sleeve and an arc-shaped opening 102 facing the filter screen, and the material of the mold mouth 10 is ceramic, not metal.

[0024] The advantage of using ceramic material for the mold pot 10 is that it has a long service life, which is generally replaced once every 30-60 days, while the existing iron pot needs to be replaced every 1-2 days. In addition, the ceramic soup mouth riser has a better effect of bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com