Transverse buffers for train bogies

A technology of transverse buffers and bogies, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, and can solve problems such as large vibration and noise, low running quality, and poor train safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

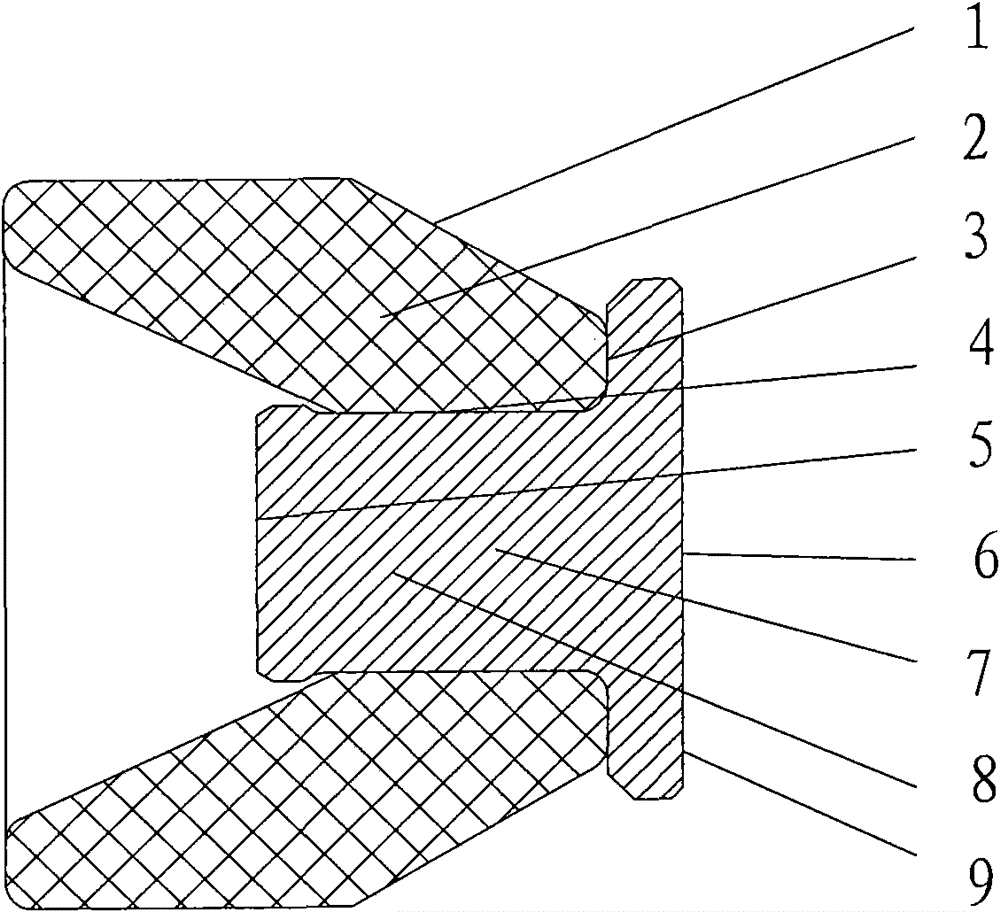

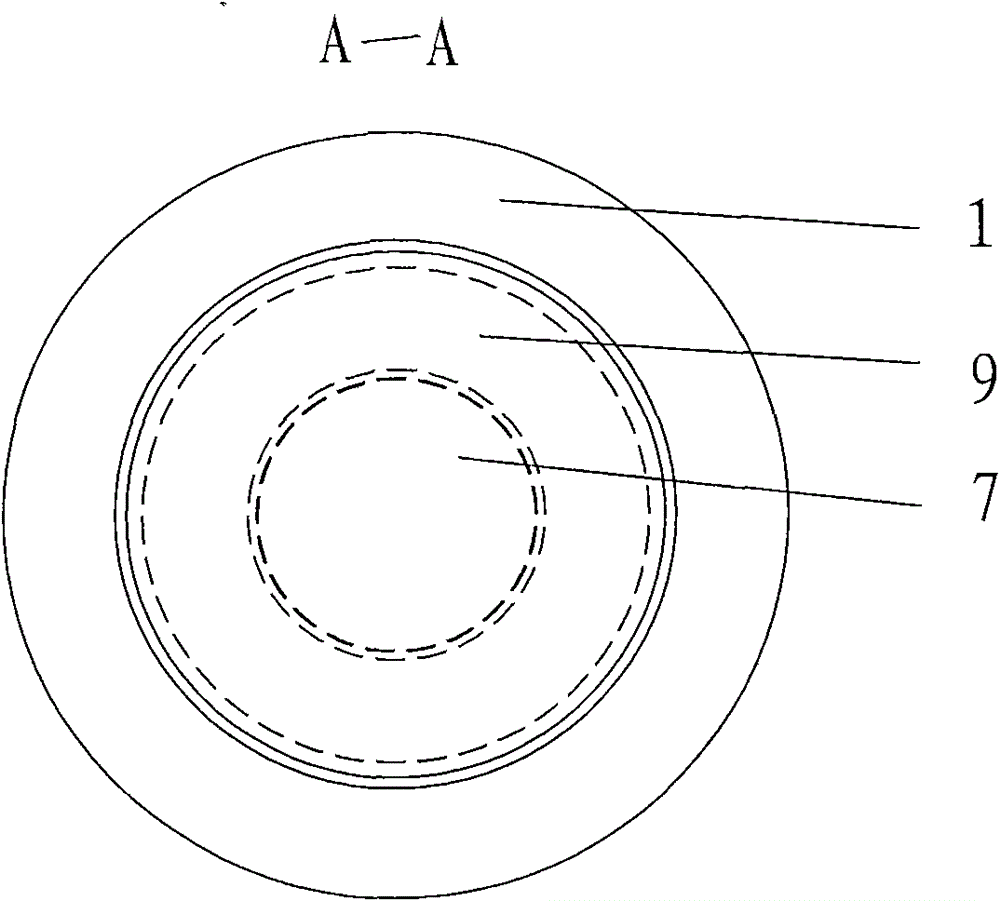

[0013] As shown in each figure: a transverse buffer of a train bogie, which includes a blocking shaft 9 and a rubber blocking 1.

[0014] Described stop shaft 9 adopts metal material to make. The right end of the blocking shaft 9 is a large oblate cylinder 6, and the left end of the blocking shaft 9 is an elongated cylinder 8. The left end 5 of the elongated cylinder is slightly thicker than the middle part 7 of the elongated cylinder.

[0015] The rubber stopper 1 is made of rubber material. The right end of the rubber stopper 1 is thick and the left end is thin in the shape of a conical hollow cone 2 . The right end 3 of the tapered hollow cone abuts against the large oblate cylinder 6 of the blocking shaft 9 . The inner ring 4 of the tapered hollow cone is set on the outer ring of the middle part 7 of the elongated cylinder.

[0016] The said retaining shaft 9 and the rubber retainer 1 are integrally bonded together by the rubber vulcanization of the rubber retainer 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com