High pressure combustion method for blast-furnace hot blast stove

A hot blast stove and blast furnace technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as wasting energy, and achieve the effects of improving heat storage capacity, increasing air supply temperature, and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

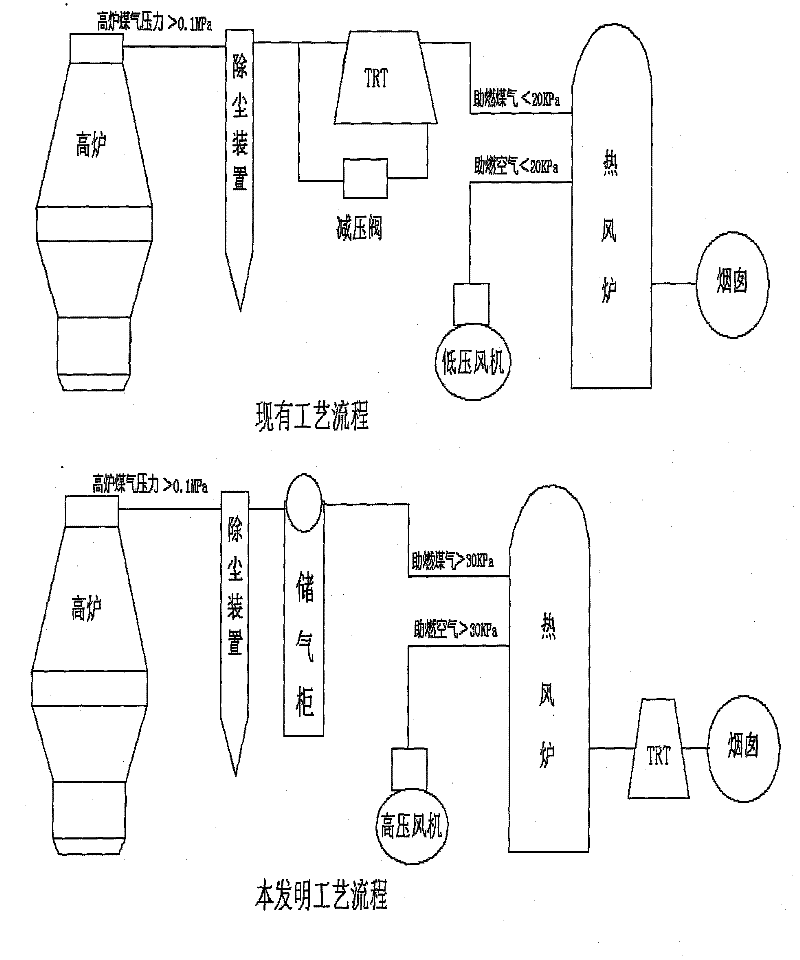

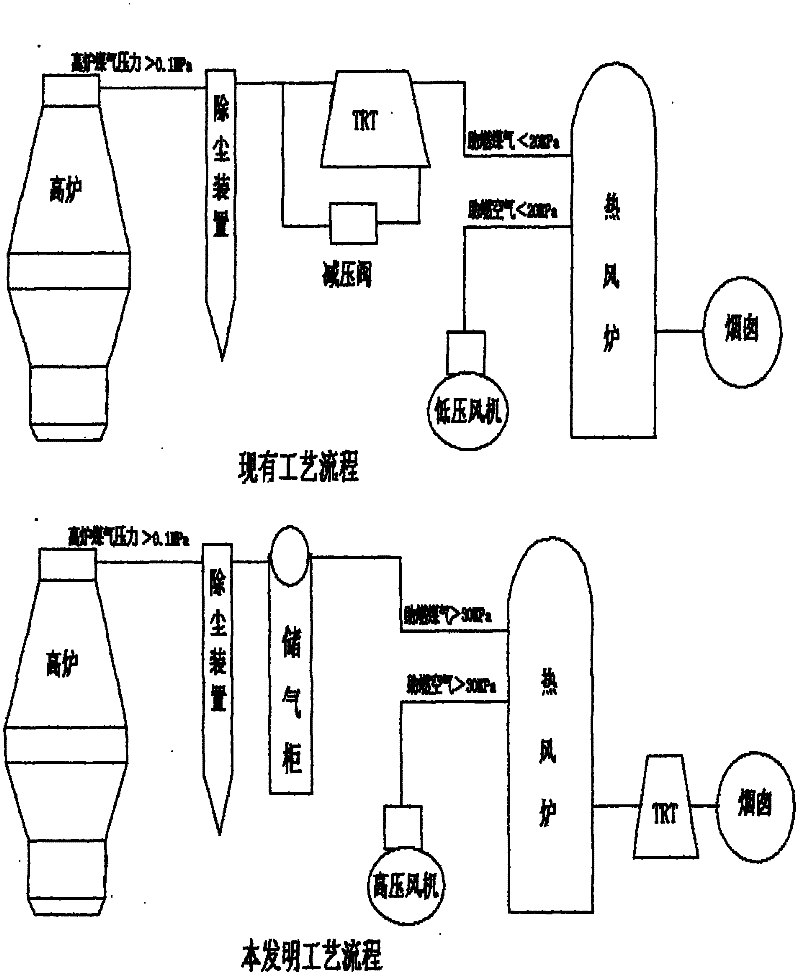

[0005] The blast furnace gas is directly sent to the hot blast stove after passing through the dust removal device and the buffer device, so as to keep the gas pressure loss as small as possible. To increase the pressure of the combustion-supporting gas when entering the hot blast stove. Depending on the size and operation mode of the blast furnace, the pressure range of the blast furnace gas is generally between 100KPa-500KPa. The combustion-supporting air is blown in by a high-pressure fan, and the inlet pressure of the combustion-supporting air is the average value of the inlet pressure of the combustion-supporting gas to ensure that the burner in the hot blast stove works normally. The exhaust gas generated by the combustion of the hot blast stove is sent to the TRT (residual pressure recovery turbine power generation device) to recover the residual pressure and waste heat.

[0006] In order to ensure the absolute safety of the hot blast stove under high pressure during c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com