Time-sharing preheating system for combustion-supporting air of hot-blast stove

A combustion-supporting air and hot blast stove technology, which is applied in the field of hot blast stoves in the metallurgical industry, can solve the problems of low cost input, large energy consumption, and high operating costs, and achieve the effects of strong applicability, efficient recovery, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

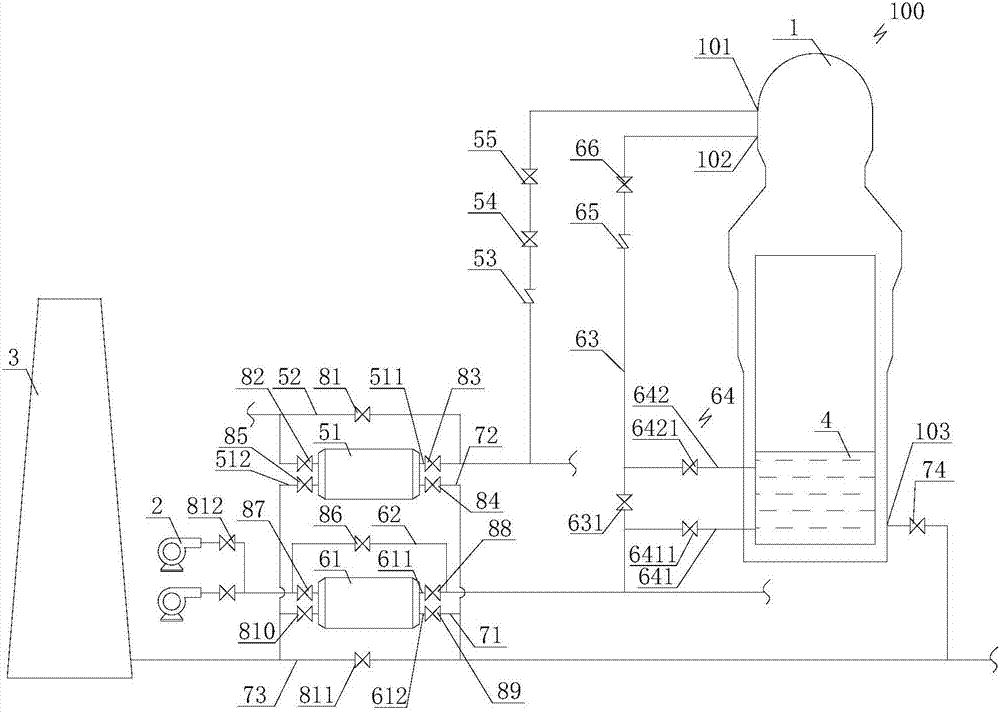

[0049] Such as figure 1 As shown, the present invention provides a time-sharing preheating system 100 for hot blast stove combustion-supporting air, including a hot blast stove 1 and a combustion-supporting fan 2. In this embodiment, the hot blast stove 1 can be top-combustion, external combustion, internal combustion or Spherical hot blast stoves and other different forms, the number of hot blast stoves is multiple, and the plurality of hot blast stoves are arranged in parallel; the top of the hot blast stove 1 is provided with a gas inlet 101 and a combustion air inlet 102, and the bottom of the hot blast stove 1 is arranged There is a waste gas outlet 103, and the waste gas outlet 103 communicates with the bottom of the chimne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com