X130 pipe line steel with low yield ratio and ultrahigh strength and manufacturing method of hot rolled flat plate of X130 pipe line steel

A technology with ultra-high strength and low yield-to-strength ratio, applied in temperature control and other directions, can solve the problems of increasing manufacturing cost and process complexity, unfavorable high-strength pipeline steel engineering application, low yield strength, etc., to simplify the composition design scheme, flexible Hot rolling production process, the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below by way of examples.

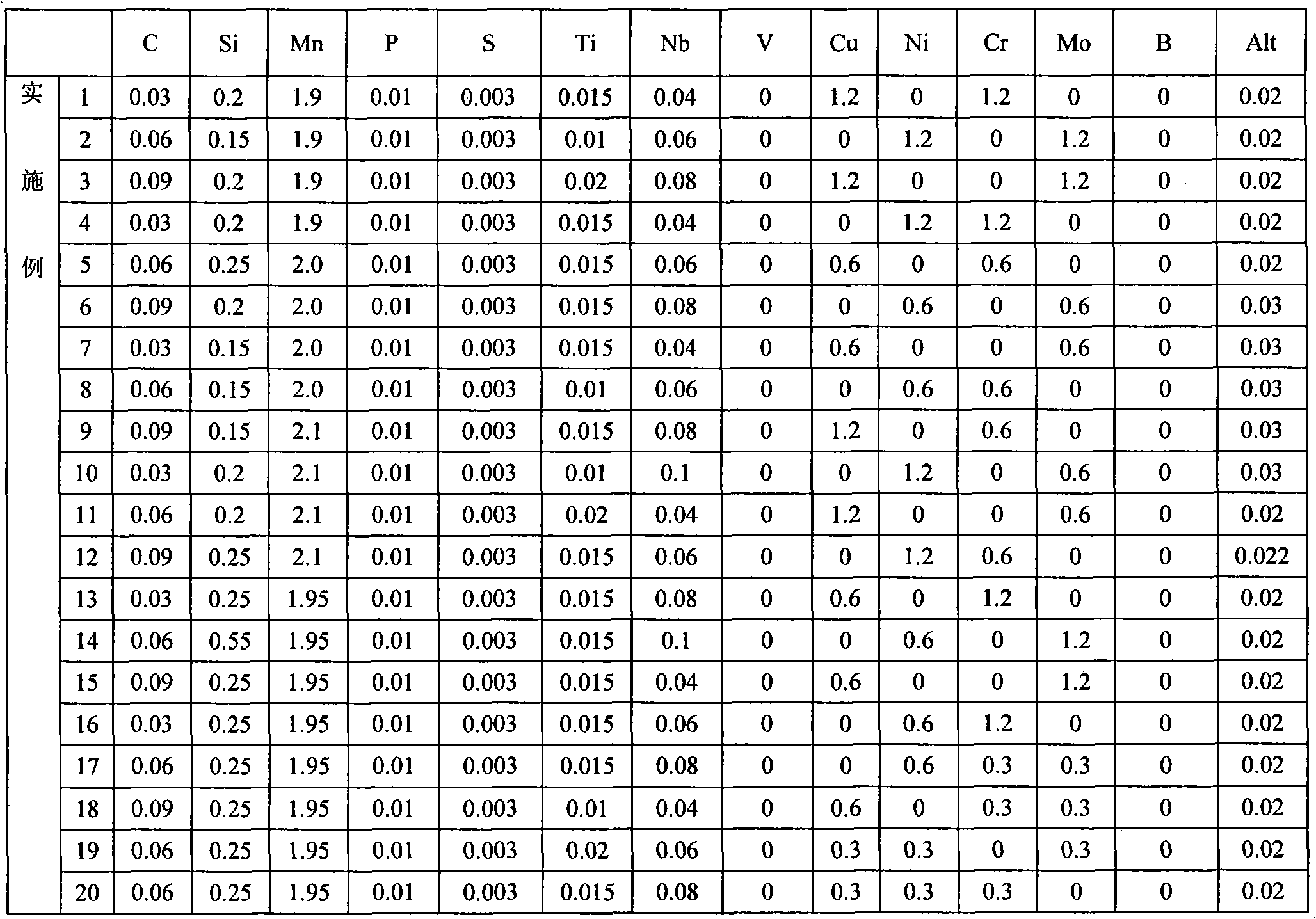

[0038] The chemical composition of the steel of the embodiment of the present invention is shown in Table 1. Among them, comparative examples 24 and 25 are from WO2008 / 054166Al patent, and comparative example 26 is from JP2003003233 patent. The hot rolling process parameters of the steel in the embodiment of the present invention are shown in Table 2. The mechanical properties of the steels in the examples of the present invention are shown in Table 3.

[0039] Table 1 The chemical composition (wt%) of the embodiment steel of the present invention

[0040]

[0041]

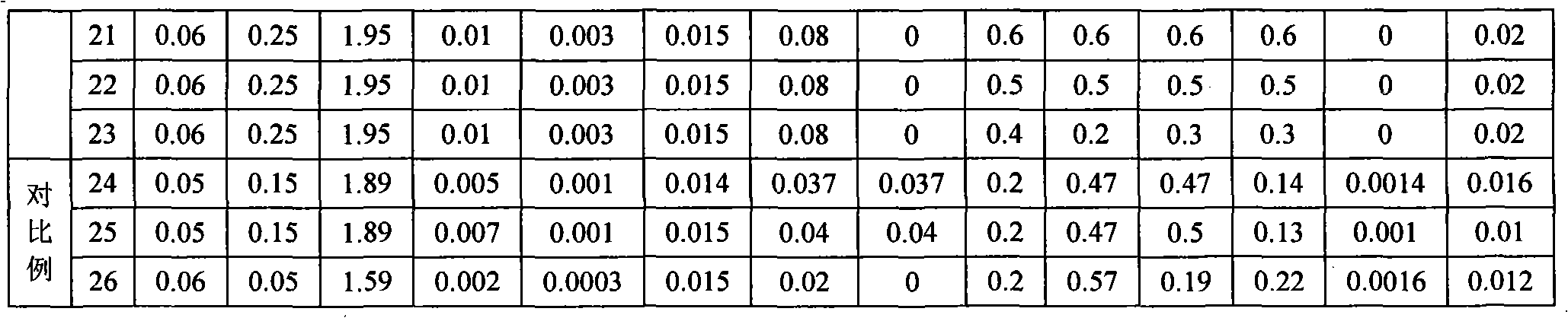

[0042] The hot-rolling process of table 2 embodiment steel of the present invention

[0043]

[0044] Note: * means that the original patent did not provide specific values of relevant parameters.

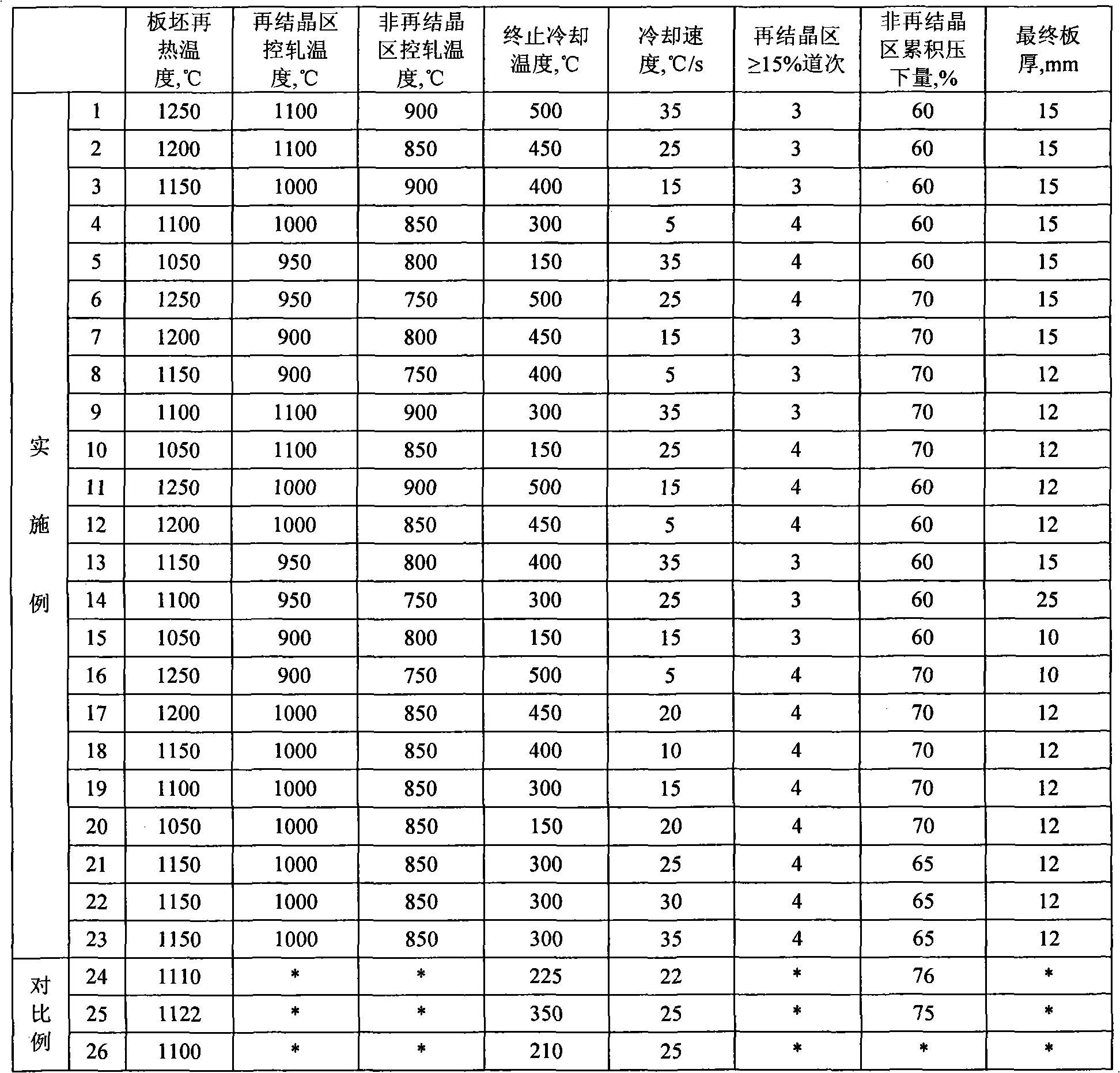

[0045] The mechanical property of table 3 embodiment steel of the present invention

[0046]

[0047] Note: * means ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com