Hydraulic circuit controlling preferred movement of moveable arm to lift or rotate

A hydraulic circuit and action technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of uncoordinated body rotation and slow swing of the boom, and achieve The effect of reducing energy consumption, increasing comfort and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

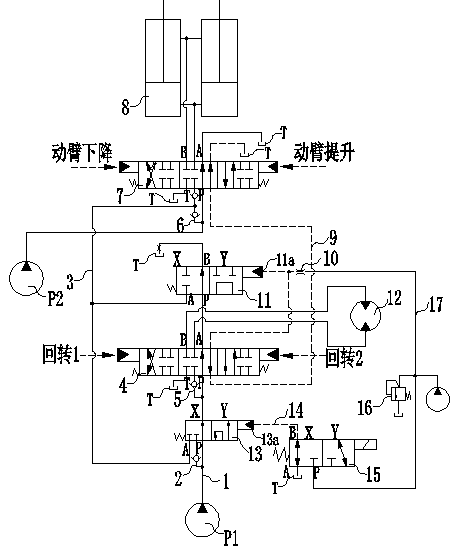

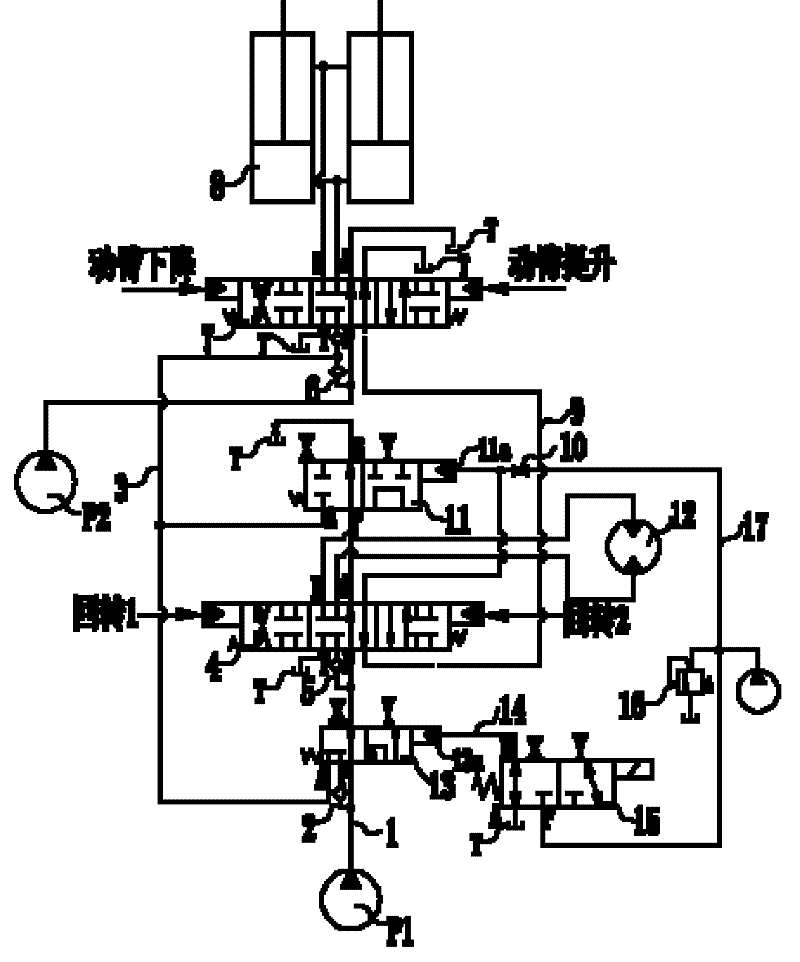

[0020] Such as figure 1 The hydraulic circuit shown to control the lift and swing priority motion of the excavator boom has:

[0021] The hydraulic actuator includes the rotary motor 12 of the rotary platform and the lifting cylinder 8 of the boom.

[0022] The hydraulic pumps include a first hydraulic pump P1 for driving the hydraulic actuator, a second hydraulic pump P2, and a pilot oil pump P3 for providing a pilot pressure oil source.

[0023] Boom control valve 7, the boom control valve 7 is installed downstream of the second hydraulic pump P2 and upstream of the boom lifting cylinder 8, the inlet P port of the boom control valve 7 is connected to the bypass oil circuit 6 with a check valve, The outlets A and B are connected to the boom lifting cylinder 8, and the control signal is the hydraulic control signal or electric control signal output by the joystick, and the control signal input from the joystick makes the spool of the boom control valve 7 switch, thereby The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com