Refuse derived fuel rotary wind-locking loading and unloading device and method

A garbage-derived fuel and loading and unloading device technology, applied in the direction of combustion method, fuel supply, combustion equipment, etc., can solve the problems of unfavorable environmental protection, high cost, stuck transmission device, etc., to avoid large space, improve environmental protection, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

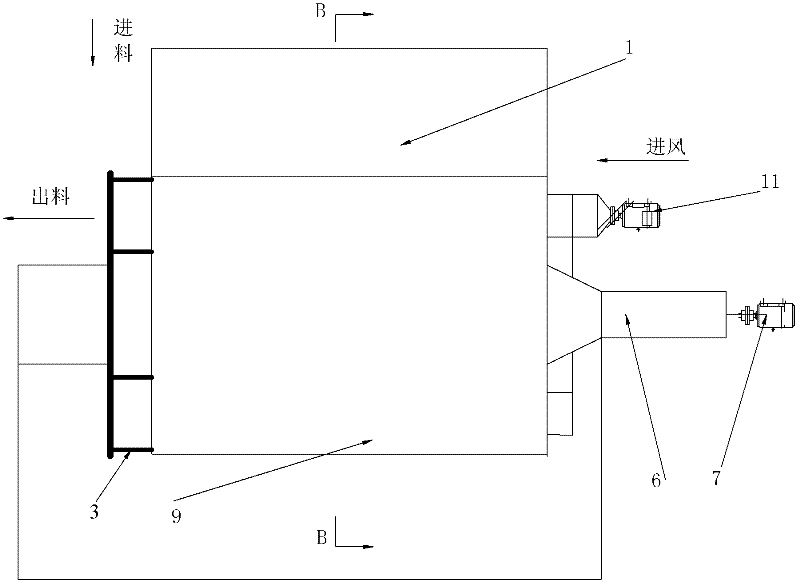

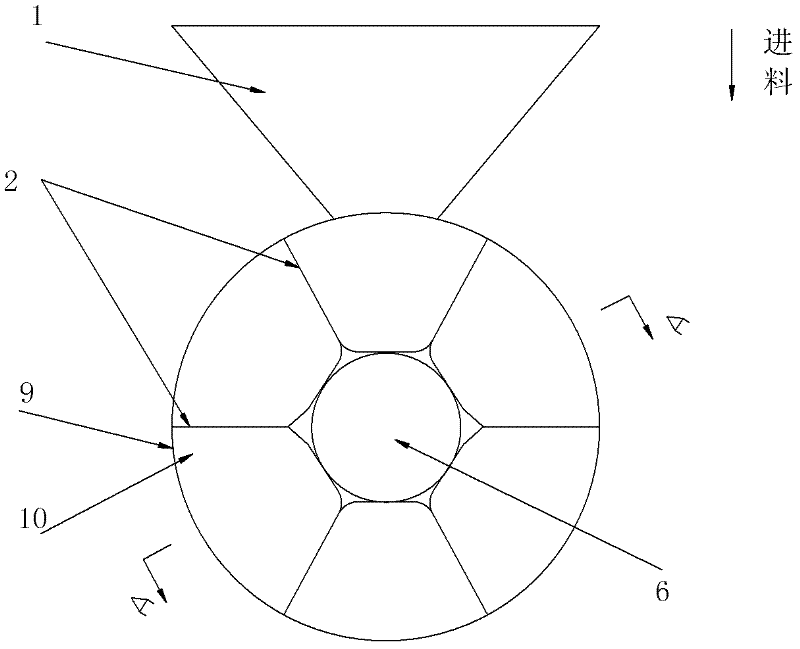

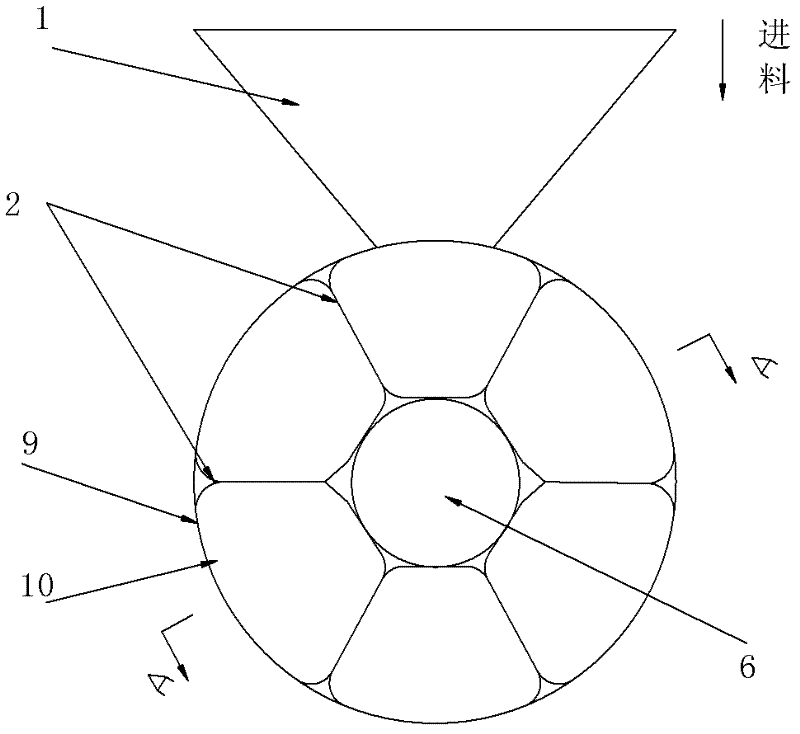

[0031] Attached below Figure 1-4 The device of the present invention is further described.

[0032] Such as Figure 1-4 As shown, the garbage-derived fuel rotary windlock loading and unloading device used in the present invention mainly includes a hopper 1, a cylinder 9, a rotor 6, and a drive motor 7. The cylinder 9 is placed horizontally, and the hopper 1 is positioned above the cylinder 9 and connected to the The cylinder 9 is docked, the rotor 6 is horizontally located inside the cylinder 9 and one end of the rotating shaft of the rotor 6 is connected to the drive motor 7; it is characterized in that the rotor 6 is provided with a plurality of blades 2, the blades 2 and the blades 2 and the inner wall of the cylinder 9 Separate independent rotating material storage spaces 10 are formed between them, and the cylinder wall corresponding to each rotating material storage space 10 is provided with a feeding port matching the discharge end of the hopper; Figure 4 It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com