Point-by-point correcting system and point-by-point correcting method for LED display screen

An LED display, point-by-point correction technology, used in static indicators, cathode ray tube indicators, instruments, etc., can solve problems such as uneven chromaticity, eliminate snow spots and pits, and improve chromaticity uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

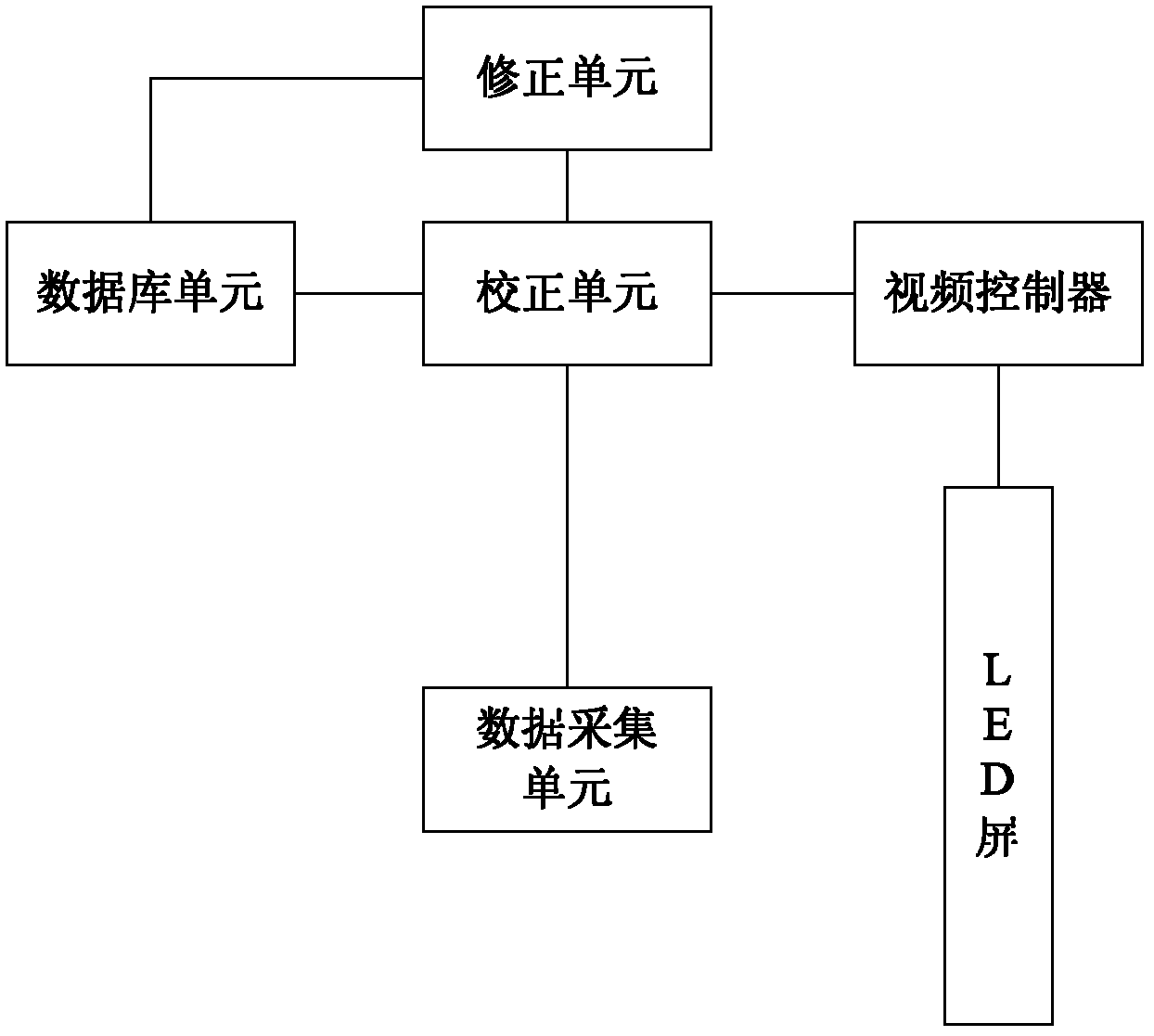

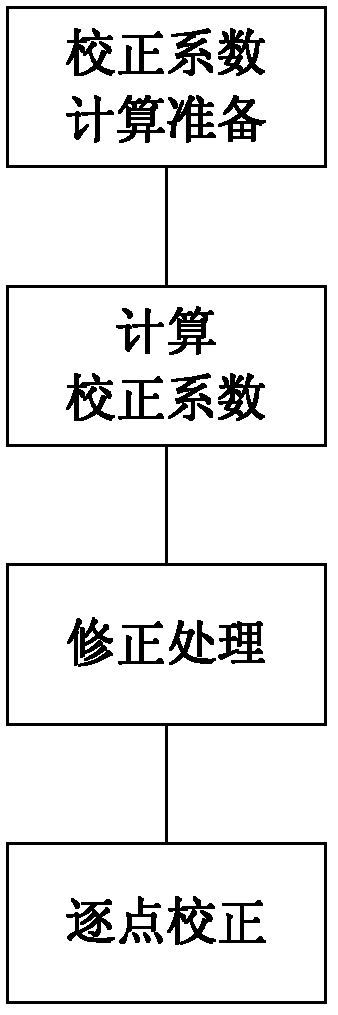

[0033] A point-by-point correction system for an LED display provided in this specific embodiment is as follows: figure 1 As shown, it includes: LED display screen, data acquisition unit, correction unit, correction unit and video controller; the data acquisition unit is connected with the correction unit, and the correction unit is connected with the LED display screen through the video controller, and the correction unit Connect to calibration unit. In actual use, the calibration unit and the correction unit can be the calibration software and the correction software running on the host computer, and the correction software can actually be a correction module in the correction software. Since the correction unit is set, the correction coefficient can be corrected, so while improving the chromaticity uniformity of the LED display screen, the phenomena of snowflakes and pitting can also be eliminated.

[0034]In a preferred technical solution, the LED display point-by-point c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com