Ventilation structure for slip ring cover of wound-rotor motor

A technology of wire wound motor and slip ring cover, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc. It can solve the problems of unsmooth discharge of toner, affect the operation of the motor, and affect the cooling of slip rings, etc., so as to eliminate hidden dangers in use , Reduce the accumulation of toner and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

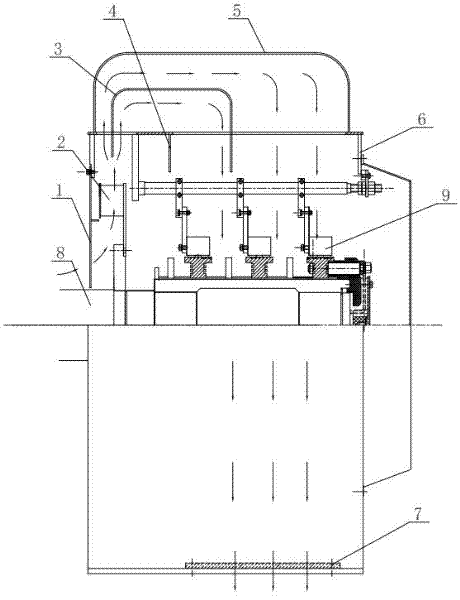

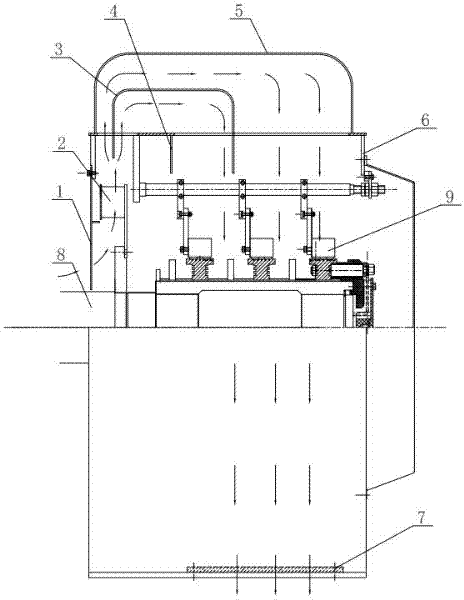

[0012] Such as figure 1 As shown, the present invention is provided with fan blades 2 inside the front side air inlet of the casing 6, the fan blades 2 are driven by the motor shaft 8, and the outer wind deflector 5 is arranged on the upper part of the casing 6, and passes through the lower part of the outer wind deflector 5. Bending inner deflectors 3 and straight inner deflectors 4 construct a number of air passages, and the outlets of the air passages are respectively located at the upper part of each set of slip rings 9 and windings; and bending inner deflectors 3 and straight inner deflectors 4 The end is designed with a smaller air collection port. An air outlet is provided at the bottom of the casing 6 . The air inlet is equipped with an air inlet net plate 1, and the air outlet is equipped with an air outlet net plate 7 and an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com