Mixed higher-order deformed elliptical gear planetary pot seedling transplanter seedling separation mechanism

A denatured ellipse and gear technology, which is applied in the direction of transplanting machinery, gear transmission, belt/chain/gear, etc., can solve the problem of hindering the application of the rotary planetary gear system, increasing the rate of seedling damage and missing seedlings, and the transplanting machine The vibration of the frame is aggravated and other problems, and the effect of light weight, high work efficiency and small vibration is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

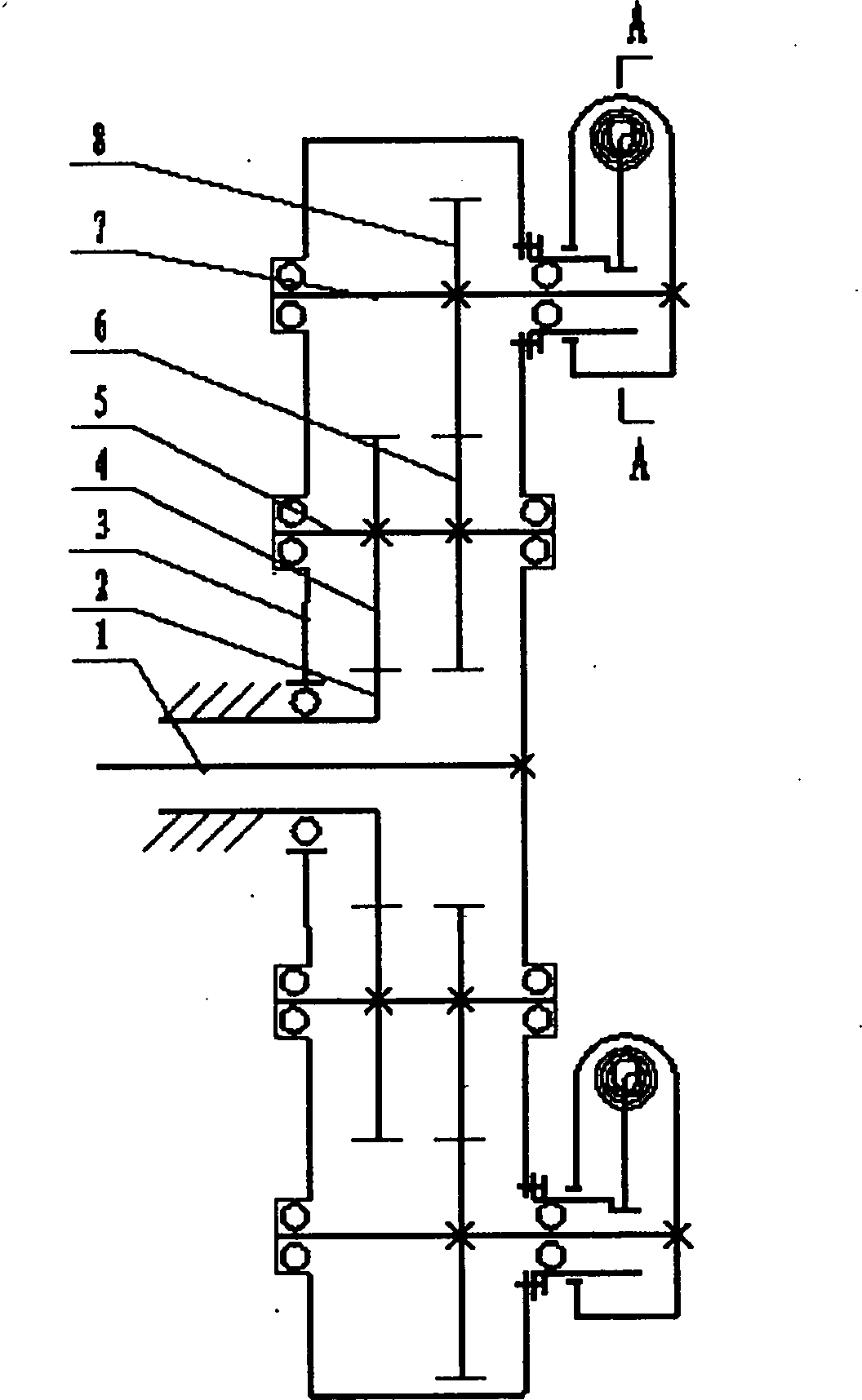

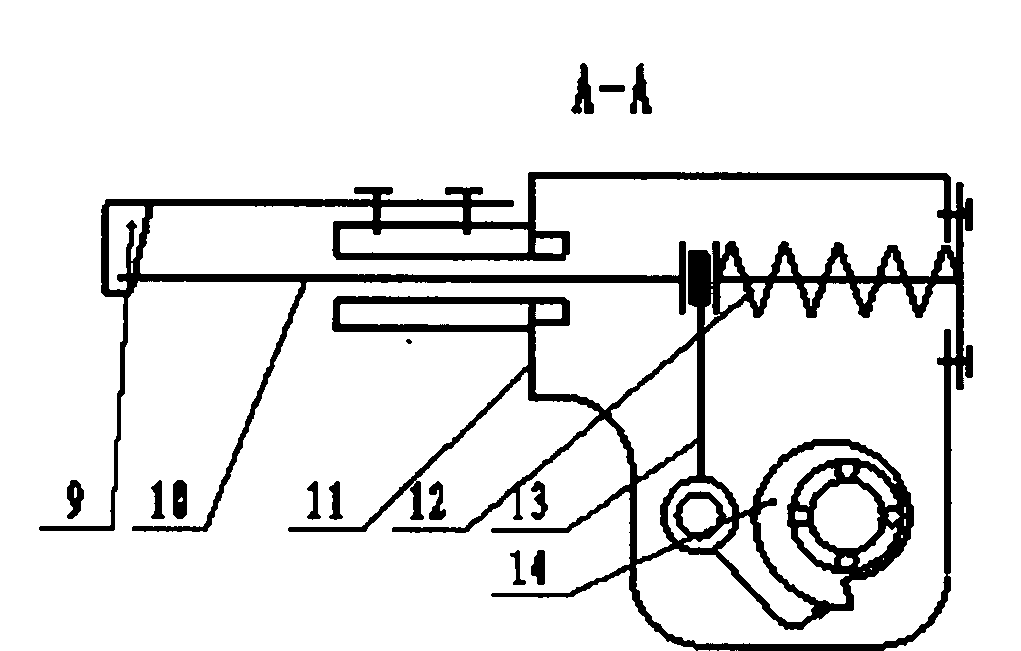

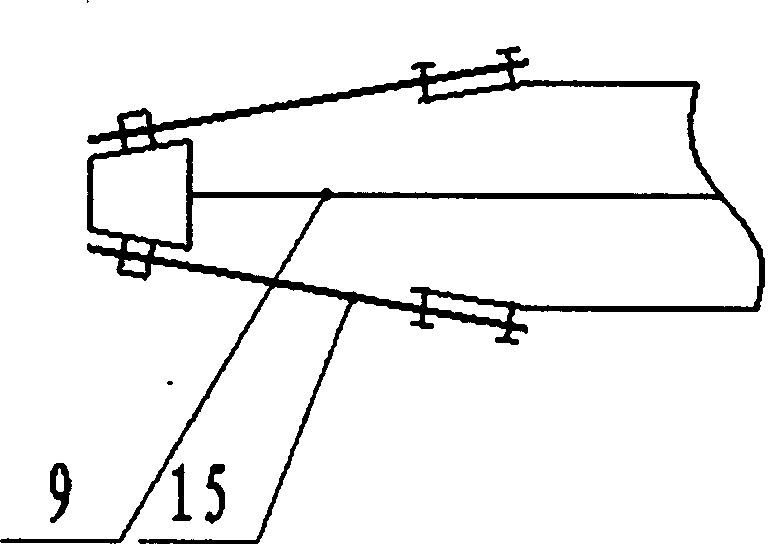

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] A hybrid high-order denatured elliptical gear planetary system seedling-separating mechanism for pot seedling transplanting machines. The sun denatured oval gear 2 is rotatably installed on the center of the gear housing 3, and the driving central shaft 1 is rotatably inserted into the sun denatured oval gear. In the central hole of the shaped gear 2, one end of the driving central shaft 1 is fixedly connected to the gear housing 3; on the inner side of the gear housing 3, the intermediate axles 5 are respectively fitted parallel to each other at the symmetrical positions on both sides of the driving central shaft 1, Intermediate denatured oval gears 4 and intermediate denatured oval gears 6 are fitted on the intermediate wheel shafts 5 on both sides, and the intermediate denatured oval gears 4 mesh with sun denatured oval gears 2 to form a seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com