Double-section ice cream cone and production method thereof

A production method, crisp tube technology, applied in baking, frozen desserts, dough processing, etc., can solve the problem of no face, etc., and achieve the effect of strong novelty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

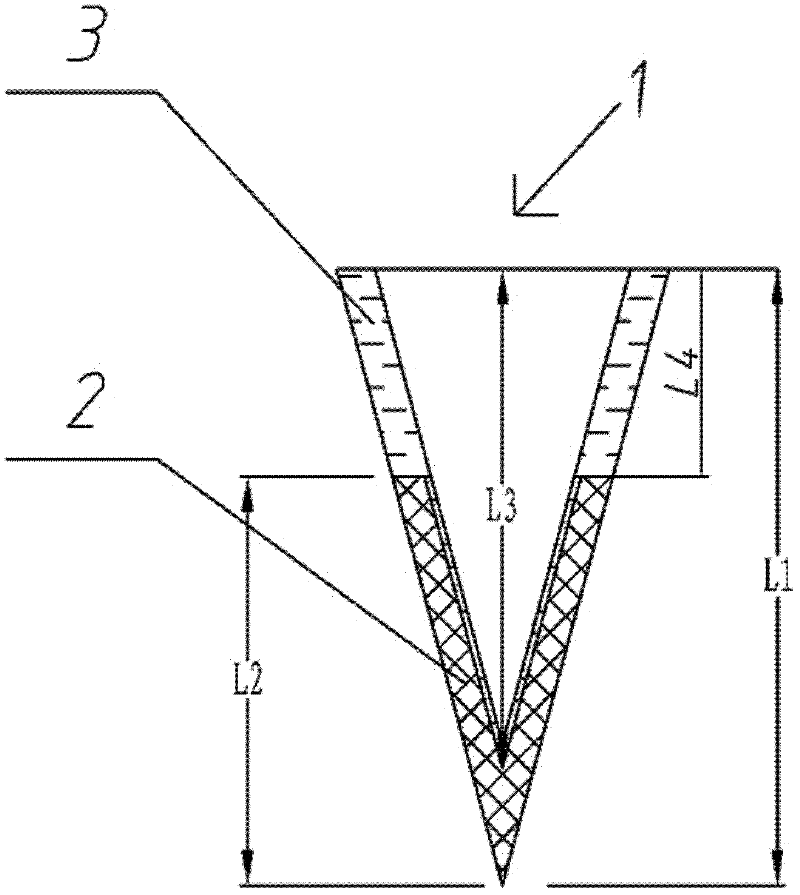

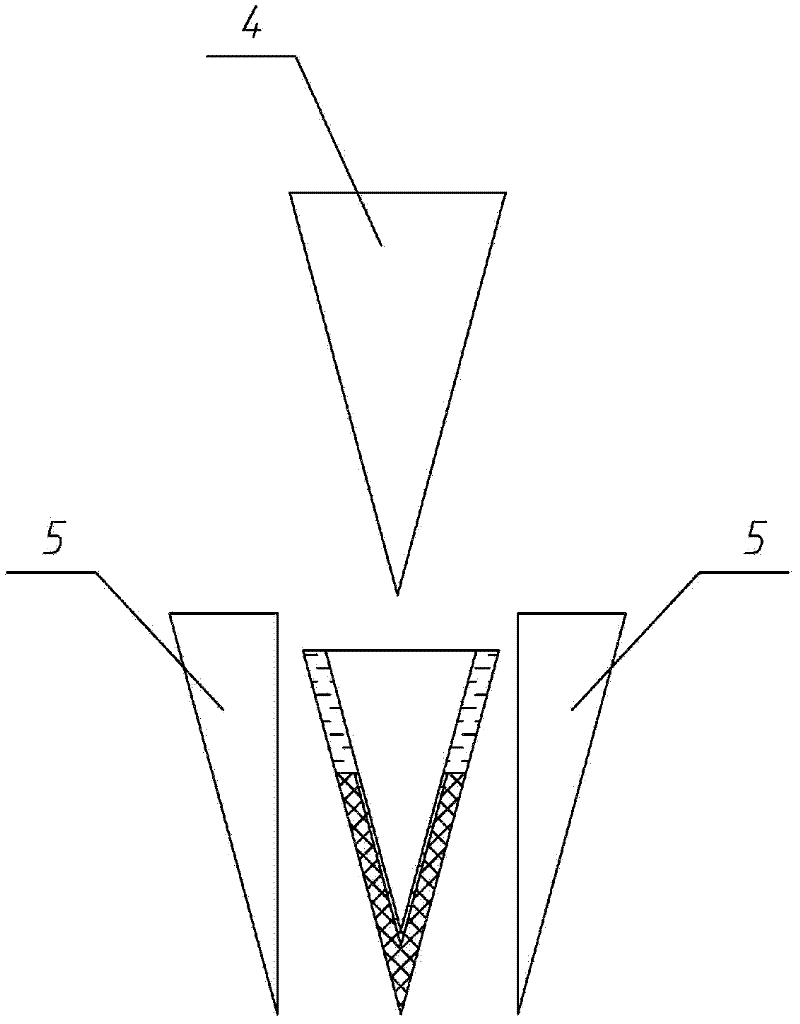

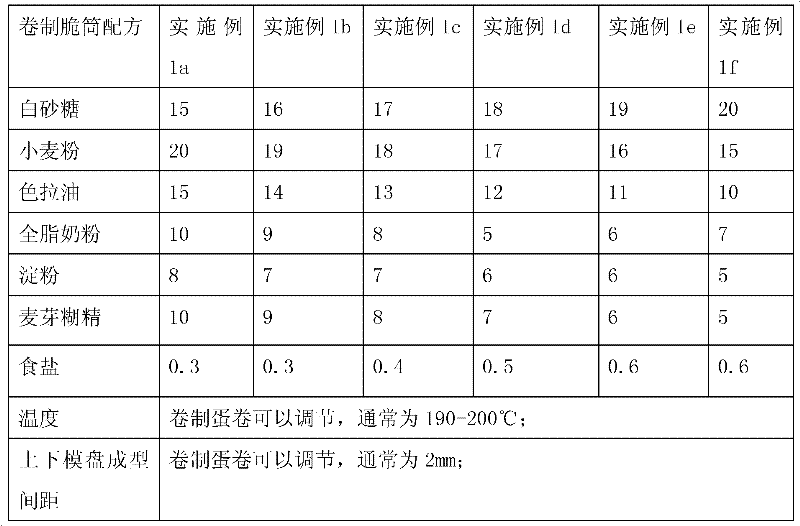

[0022] The lower half of the double-section crispy tube 1 is in the form of rolled crispy tube 2, and the taste is very crispy. When making it, a roll-rolled egg roll machine is used. The upper part of the double-section crispy tube 1 is in the form of the wafer crispy tube 3, and the wafer is fluffy in taste. When making it, a mold-closing baking egg tray machine is used. Rolling egg roll machine and mold closing baking egg tray machine are all existing forming equipment. The difference between rolled crispy tube 2 and wafer crispy tube 3 is that there is a big difference in taste, and the raw materials used in formulating the formula are different.

[0023] In the vertical direction of the double-section crispy tube, the height L2 of the rolled crispy tube accounts for one-third to two-thirds of the height L1 of the double-section crispy tube; in the vertical direction of the double-section crispy tube, the height of the wafer crispy tube is L3 Accounting for one-third to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com